The primary benefits of using a honey filling machine are increased accuracy, speed, and consistency in your packaging process. These advantages directly lead to minimal product waste, improved hygiene, and a higher quality, more professional final product.

The core challenge in packaging honey is its high viscosity, which makes manual filling slow, messy, and inconsistent. A specialized honey filling machine is not just about speed; it's an engineered solution designed specifically to handle this unique characteristic, transforming a difficult manual task into a streamlined, scalable business operation.

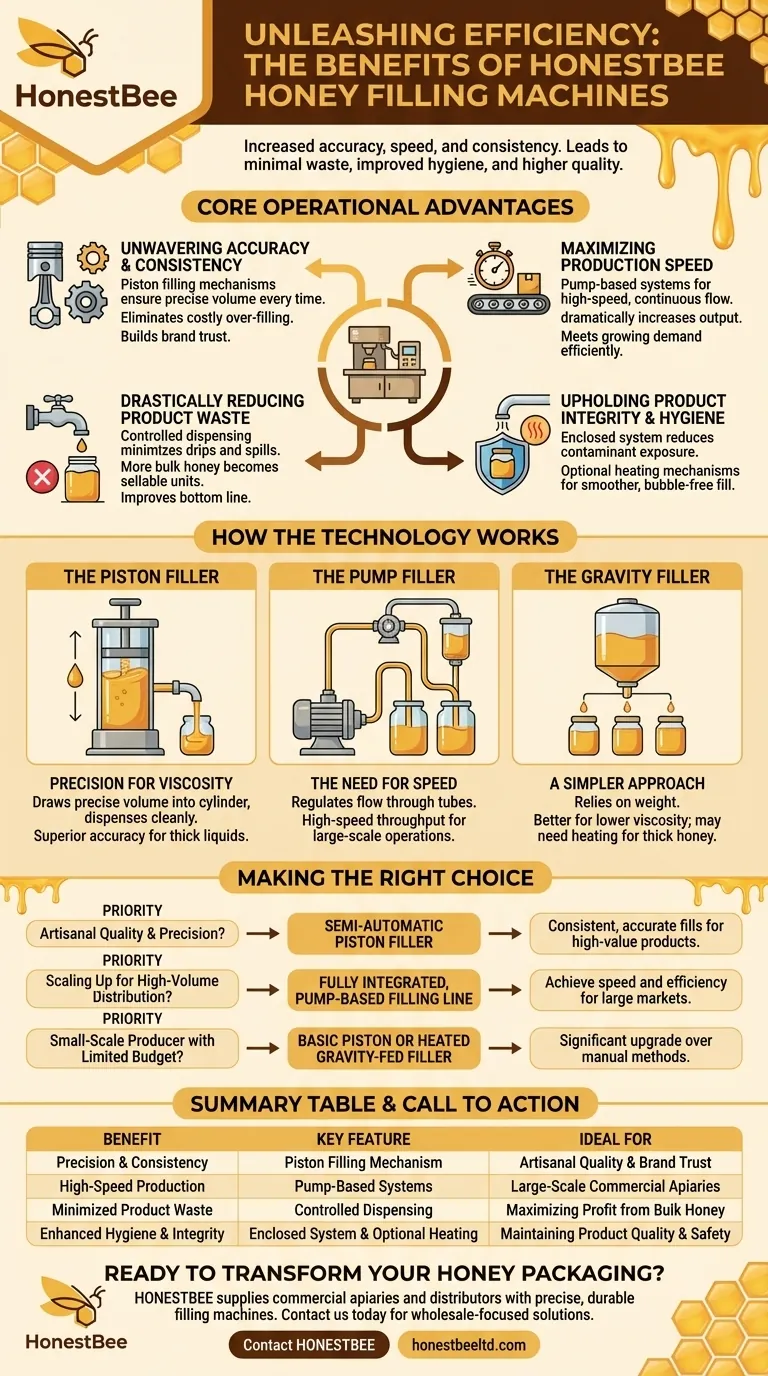

The Core Operational Advantages

A honey filling machine addresses the most significant bottlenecks in honey production, offering clear advantages over manual or non-specialized methods. Each benefit contributes directly to efficiency and profitability.

Unwavering Accuracy and Consistency

Automated fillers dispense the exact same volume of honey into every container, every single time. This eliminates costly over-filling and ensures customers receive precisely what they paid for, building brand trust.

This level of precision is typically achieved through piston filling mechanisms, which are ideal for thick liquids.

Maximizing Production Speed

The most obvious benefit is a dramatic increase in output. An automated system can fill, cap, and seal containers far faster than any manual process, allowing you to meet growing demand without a proportional increase in labor.

For high-volume needs, pump-based systems are often used to regulate a continuous, high-speed flow of honey into jars.

Drastically Reducing Product Waste

Spills and inaccurate fills during manual processing result in lost product and lost revenue. A filling machine's controlled dispensing minimizes drips and overfills, ensuring that nearly all your valuable honey ends up in the final package.

This efficiency means more of your bulk honey is converted into sellable units, directly improving your bottom line.

Upholding Product Integrity and Hygiene

Automated systems enclose the honey during the filling process, significantly reducing its exposure to airborne contaminants compared to open, manual methods. This helps maintain the honey's natural integrity and ensures a safe, hygienic product.

Many machines also include optional heating mechanisms to gently reduce the honey's viscosity, allowing for a smoother, bubble-free fill without damaging its delicate properties.

How the Technology Works

Different filling machines use distinct mechanisms to handle honey. Understanding these methods helps clarify which type is best suited for a particular scale of operation.

The Piston Filler: Precision for Viscosity

This is the most common and effective method for honey. A piston draws a precise volume of honey into a cylinder and then dispenses it cleanly into the container.

This mechanism provides exceptional volumetric accuracy, making it the superior choice for handling thick, viscous liquids like honey where consistency is paramount.

The Pump Filler: The Need for Speed

In high-speed, large-scale operations, pump fillers are used. These systems regulate the flow of honey through tubes and into containers, often controlled by a timer or flow meter.

While very fast, they may require more calibration to achieve the same level of pinpoint accuracy as a piston filler, especially for smaller containers.

The Gravity Filler: A Simpler Approach

Gravity fillers rely on the weight of the honey in an overhead tank to fill containers below. This method is simpler and often less expensive.

However, it is better suited for lower viscosity liquids. For honey, it can be slow and less precise unless paired with a heating system to make the honey flow more easily.

Understanding the Trade-offs

Investing in a honey filling machine requires balancing competing priorities. There is no single "best" machine, only the one that is right for your specific goals.

Precision vs. Speed

There is often a trade-off between fill accuracy and overall speed. Piston fillers offer the highest level of precision but may operate at a more moderate pace. Pump-based systems prioritize high-speed throughput, which may be a better fit for large commercial producers.

Equipment Cost and Complexity

A simple, semi-automatic piston filler is a significant step up from manual filling. However, a fully automated line with container cleaning, filling, capping, and labeling capabilities represents a much larger capital investment. Your production volume must justify the complexity.

The Viscosity Challenge

Not all machines handle thick, crystallized honey well. A basic gravity filler may struggle, leading to slow fills and inaccuracies. A machine equipped with a gentle heating system and a powerful piston mechanism is purpose-built to overcome this challenge, but it comes at a higher cost.

Making the Right Choice for Your Operation

Selecting the correct machine is critical for scaling your business effectively. Your decision should be guided by your primary operational goal.

- If your primary focus is artisanal quality and precision: A semi-automatic piston filler will provide consistent, accurate fills that reflect the high value of your product.

- If your primary focus is scaling up for high-volume distribution: A fully integrated, pump-based filling line is necessary to achieve the speed and efficiency required for large markets.

- If you are a small-scale producer with a limited budget: A basic piston or heated gravity-fed filler offers a significant and worthwhile upgrade over purely manual methods.

Ultimately, the right honey filling machine transforms your packaging process from a bottleneck into a professional, efficient, and profitable asset.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Precision & Consistency | Piston Filling Mechanism | Artisanal Quality & Brand Trust |

| High-Speed Production | Pump-Based Systems | Large-Scale Commercial Apiaries |

| Minimized Product Waste | Controlled Dispensing | Maximizing Profit from Bulk Honey |

| Enhanced Hygiene & Integrity | Enclosed System & Optional Heating | Maintaining Product Quality & Safety |

Ready to transform your honey packaging into a scalable, profitable operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the precise, durable honey filling machines they need to grow. Whether your priority is artisanal precision for high-value products or high-speed throughput for large-scale distribution, our wholesale-focused operations provide the right equipment to boost your efficiency and protect your bottom line.

Contact HONESTBEE today to discuss the best filling solution for your apiary's needs.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why are automated honey filling machines critical for the commercialization of honey? Build a Consistent, Scalable Brand

- In what way do commercial honey-filling machines indirectly support the stability of grain production? Economic Insights

- Why is the use of professional filling and sealing packaging machinery necessary for the production of high-value honey?

- In what way does professional honey-filling equipment ensure the purity of the final product? Maintain Residue-Free Quality

- How do high-precision honey-filling machines contribute to the incentive mechanisms for pollination services?

- What advantages does industrial honey filling and bottling equipment offer? Boost Efficiency and Product Purity

- What are the primary benefits of using automatic honey-filling machines? Scale Your Commercial Production and Efficiency

- How does a volumetric filling machine work? Achieve Precise Volume Filling for Your Products