At its core, a standard honey stick machine is a piece of equipment that produces honey sticks of a consistent size, typically 6-7 inches long and a quarter-inch wide. While the final product is standardized, the machines themselves vary dramatically in their operation, speed, and level of automation. The defining characteristics are less about the stick and more about the machine's production capacity.

The term "standard machine" is misleading; there is no single model. Instead, you must understand a spectrum of machines, from manual-assist to fully automated, and select one based on your specific production volume, budget, and operational scale.

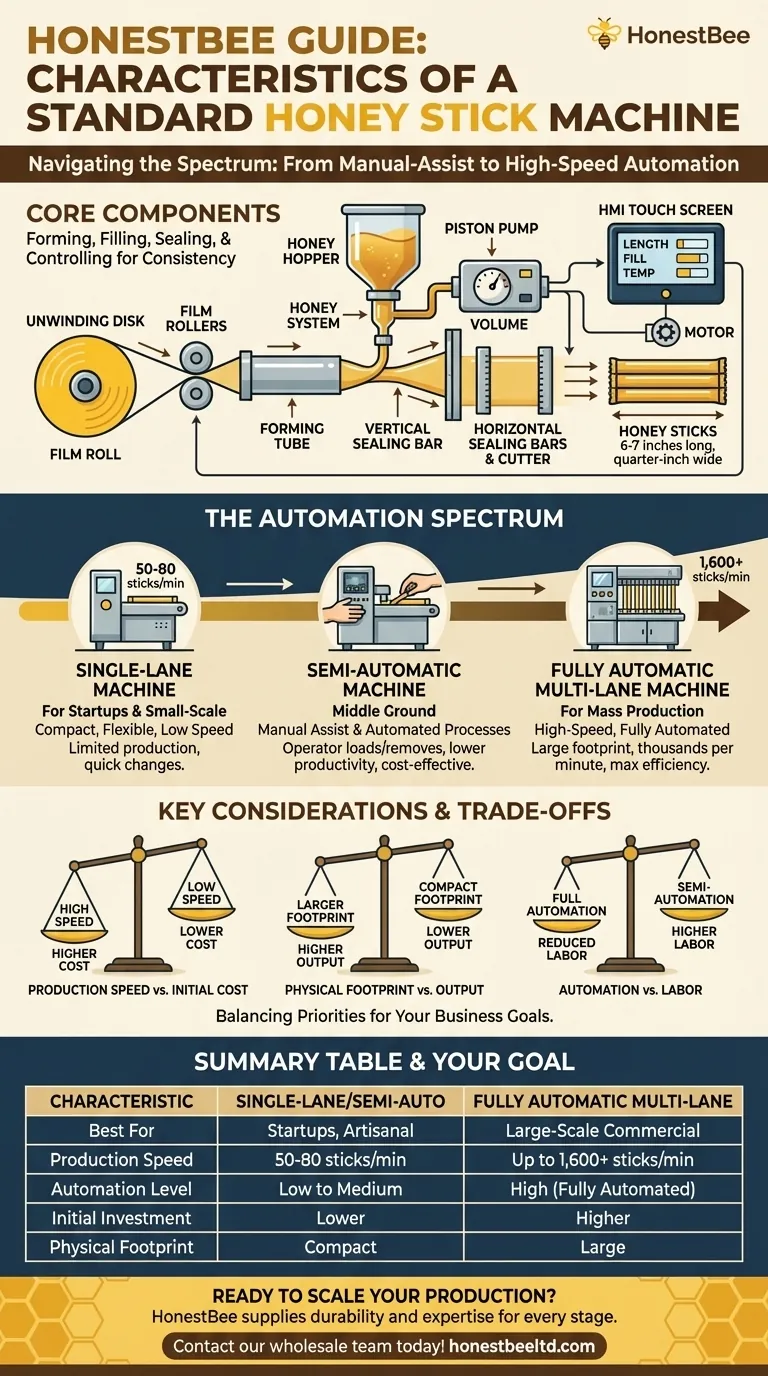

The Core Components of a Honey Stick Machine

Regardless of size or speed, all honey stick machines operate on the same fundamental principles and share a common set of components designed to form, fill, and seal the product.

The Film and Forming System

The process begins with a roll of packaging film. An unwinding disk holds this roll, feeding it through film rollers that guide it to a forming tube, which shapes the flat film into the familiar stick-like cylinder.

The Filling and Sealing Process

A honey hopper holds the bulk honey, which is then precisely measured and dispensed into the formed tube by a piston pump. Immediately after filling, a vertical sealing bar creates the long seam down the stick, while horizontal sealing bars seal and cut the individual sticks to length.

Control and Operation

Modern machines are typically managed via an HMI (Human-Machine Interface) touch screen. This control panel allows the operator to set parameters like stick length, fill volume, and temperature. A motor drives the mechanical actions, and a cutter separates the finished sticks.

Understanding the Spectrum of Automation

The most critical differentiator between machines is their level of automation, which directly correlates to their production capacity and is the key factor in your selection process.

The Single-Lane Machine: For Small-Scale and Startups

A single-lane machine is the most basic automated option. It produces one honey stick per cycle from a single lane of production.

Its compact size makes it ideal for facilities with space constraints. While its production capacity is limited, it often allows for quick part changes to produce sticks of different lengths.

The Semi-Automatic Machine: The Middle Ground

This machine blends automated processes with manual labor. An operator is typically required to load the film roll and manually remove the finished honey sticks.

The core filling and sealing actions are automated, but the manual touchpoints result in lower productivity. This makes it a suitable and cost-effective choice for small and medium-sized packaging lines.

The Fully Automatic Multi-Lane Machine: For Mass Production

Designed for large-scale operations, these machines are workhorses. They feature multiple lanes—some models have up to 20—allowing them to produce thousands of honey sticks per minute.

From loading the film to filling, sealing, and discharging the final product, the entire process is automated. This requires a much larger physical footprint and initial investment but delivers unmatched speed and efficiency.

Key Considerations and Trade-offs

Choosing the right machine involves balancing competing priorities. Understanding these trade-offs is essential to avoid making a costly mistake.

Production Speed vs. Initial Cost

The correlation is direct and unavoidable. A high-speed, multi-lane machine capable of producing 1,600 sticks per minute carries a significantly higher price tag than a single-lane model that produces 50-80 sticks per minute.

Physical Footprint vs. Output

Greater output requires a larger, more complex machine. You must ensure your facility can accommodate the physical size of a multi-lane machine if your production goals demand it.

Automation vs. Labor

Full automation reduces the need for constant operator intervention, freeing up labor for other tasks. However, semi-automatic machines, while requiring more hands-on work, have a lower barrier to entry and simpler maintenance requirements.

Making the Right Choice for Your Goal

Your decision should be driven entirely by your business objectives. Match the machine's capabilities to your production needs, not the other way around.

- If your primary focus is starting a small business or artisanal production: A single-lane or semi-automatic machine offers the lowest initial investment and greatest operational flexibility.

- If your primary focus is scaling a medium-sized operation: A semi-automatic or a twin-lane automatic machine provides a significant boost in efficiency without the cost and footprint of a massive system.

- If your primary focus is large-scale commercial distribution: A fully automatic, multi-lane machine is the only way to achieve the necessary speed, consistency, and volume for market demands.

Ultimately, selecting the right equipment is the foundational step in efficiently turning your raw product into a market-ready success.

Summary Table:

| Characteristic | Single-Lane/Semi-Auto | Fully Automatic Multi-Lane |

|---|---|---|

| Best For | Startups, Artisanal Production | Large-Scale Commercial Distribution |

| Production Speed | 50-80 sticks/minute | Up to 1,600+ sticks/minute |

| Automation Level | Low to Medium (Manual Assistance) | High (Fully Automated) |

| Initial Investment | Lower | Higher |

| Physical Footprint | Compact | Large |

Ready to scale your honey stick production efficiently?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the right honey stick machinery for their specific operational scale. Whether you're starting a small business or need a high-volume multi-lane system, we provide the durable, high-performance equipment and expert support to ensure your success.

Contact our wholesale team today to discuss your production goals and find the perfect machine for your needs.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

People Also Ask

- In what ways do automated honey-filling machines enhance the competitiveness of commercial apiaries? Scale Your Success

- How does industrial-scale honey filling equipment enhance the competitiveness of honey products? Boost Global Export Success

- Why is it necessary for commercial apiaries to utilize automated honey filling machines? Scale Your Production Safely

- How do professional honey filling and labeling machines enhance competitiveness? Boost Brand Trust and Scale Profits

- How do Automated Filling and Capping Equipment help maintain the long-term physicochemical stability of honey?

- What role do automated honey filling machines play in peak harvests? Scale Your Honey Production Efficiently

- How do industrial-grade honey filling machines contribute to the processing of honeybee products? Maximize Safety & Scale

- In what ways do automated honey-filling machines safeguard purity? Enhance Your API Quality Control