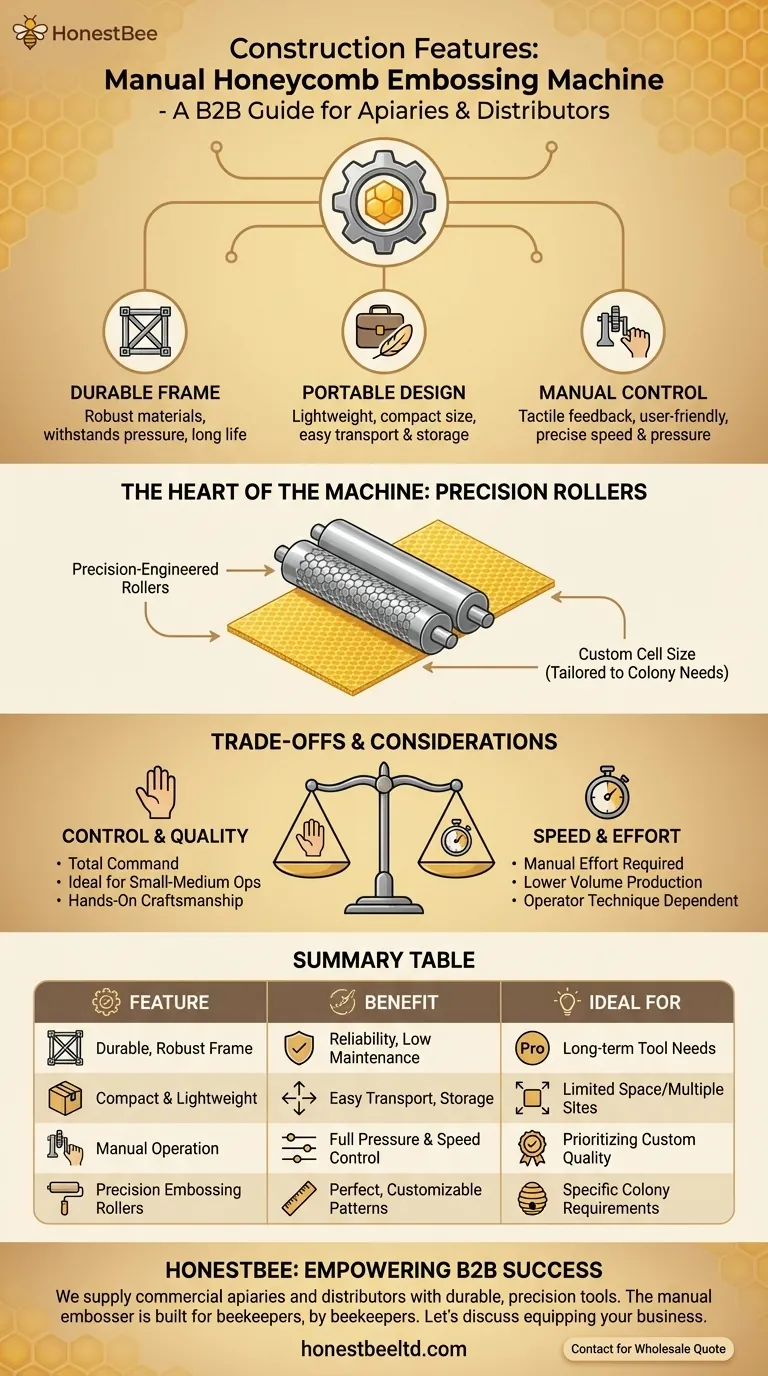

At its core, the manual honeycomb embossing machine is defined by three primary construction features: a durable, robust frame built to withstand pressure; a compact and lightweight design for portability; and a simple, manually operated mechanism that gives the user complete control over the process. These elements work together to create a reliable and user-friendly tool for beekeepers.

The machine's design philosophy is a deliberate trade-off, prioritizing hands-on control, durability, and portability over the speed of automated systems. Understanding this balance is key to determining if it fits your specific beekeeping needs.

Core Construction Principles

The design of a manual embosser is not accidental. Each feature is engineered to solve a specific challenge faced by beekeepers who wish to create their own beeswax foundation sheets.

Built for Durability and Pressure

The primary function involves pressing a precise pattern into a resistant material. The machine's frame is therefore constructed from durable materials capable of handling this repetitive stress.

This robust design ensures the machine can apply consistent and even pressure across the entire beeswax sheet, which is critical for forming perfect honeycomb cells. It also leads to longevity and minimal maintenance requirements.

Designed for Portability and Convenience

Many beekeepers work in varied locations, from workshops to barns. The machine is intentionally built to be lightweight and portable.

Its compact size is a significant feature, allowing for easy transport between locations and simple storage when not in use.

Engineered for Manual Control

The absence of a motor is a deliberate design choice. The machine is manually operated, giving the beekeeper tactile feedback and full authority over the embossing speed and pressure.

This user-friendly operation requires minimal setup and allows for a hands-on approach, which is often preferred for crafting high-quality foundation sheets.

The Heart of the Machine: The Embossing Mechanism

While the frame provides support, the actual work is done by the precision-engineered rollers.

The Embossing Rollers

The central components of the machine are two rollers engraved with the negative pattern of honeycomb cells. As a beeswax sheet is passed between them, the pattern is imprinted onto the wax.

The quality of these rollers directly determines the quality of the final foundation sheet.

Customization and Precision

A key construction feature is the ability to produce a specific honeycomb cell size. This allows beekeepers to customize their foundation sheets to match the needs of their specific bee colony, a level of control not always available with pre-made foundations.

Understanding the Trade-offs

No tool is perfect for every scenario. The manual embosser's strengths come with inherent limitations that are important to recognize.

Speed vs. Control

The greatest strength of the manual design is total control. However, this comes at the cost of speed. This machine is ideal for small to medium-sized operations but is not efficient for large-scale commercial production.

Physical Effort Required

Being manually operated means the process requires physical input from the user. Producing a large number of sheets can be labor-intensive.

Consistency Depends on the Operator

While the machine is consistent, the final quality of the embossed sheet also depends on the operator's technique. Achieving perfectly uniform results requires a bit of practice to master the right speed and pressure.

Making the Right Choice for Your Goal

To decide if this machine is the right investment, align its features with your primary objectives.

- If your primary focus is custom control and high-quality foundation for a small apiary: This machine is an excellent choice, giving you full command over cell size and material.

- If your primary focus is high-volume, commercial production: The manual process will likely be too slow, and an automated or larger-scale machine would be a more suitable investment.

- If your primary focus is portability and ease of storage: The lightweight and compact construction makes it a practical and convenient tool.

Ultimately, the manual honeycomb embossing machine is built to empower the beekeeper with direct control over one of the most fundamental elements of the hive.

Summary Table:

| Feature | Benefit | Ideal For |

|---|---|---|

| Durable, Robust Frame | Withstands high pressure, ensures longevity, minimal maintenance | Beekeepers needing a reliable, long-term tool |

| Compact & Lightweight | Easy to transport and store, highly portable | Beekeepers with limited space or multiple work locations |

| Manual Operation | Full control over pressure and speed for custom results | Beekeepers prioritizing hands-on quality over high volume |

| Precision Embossing Rollers | Creates perfect honeycomb cell patterns; customizable cell size | Beekeepers wanting to tailor foundation to their colony's needs |

Ready to take control of your foundation production?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, precision tools they need to succeed. The manual honeycomb embossing machine is just one example of our commitment to quality equipment built for beekeepers, by beekeepers.

Let's discuss how our wholesale-focused operations can equip your business for success.

Contact our team today to learn more and request a quote!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

People Also Ask

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets