Successful wax milling requires a precise balance of temperature control, lubrication, and careful handling. Key precautions include heating both the room and the mill rollers to specific temperatures, using a soap-suds water bath to prevent sticking, and handling the wax sheets in a way that avoids stretching or distorting the final foundation.

The core principle of milling wax is to make the wax pliable enough to emboss without becoming so soft that it sticks or deforms. Mastering this process is about meticulously controlling your environment, your equipment, and your technique to prevent damage to both the wax and the mill itself.

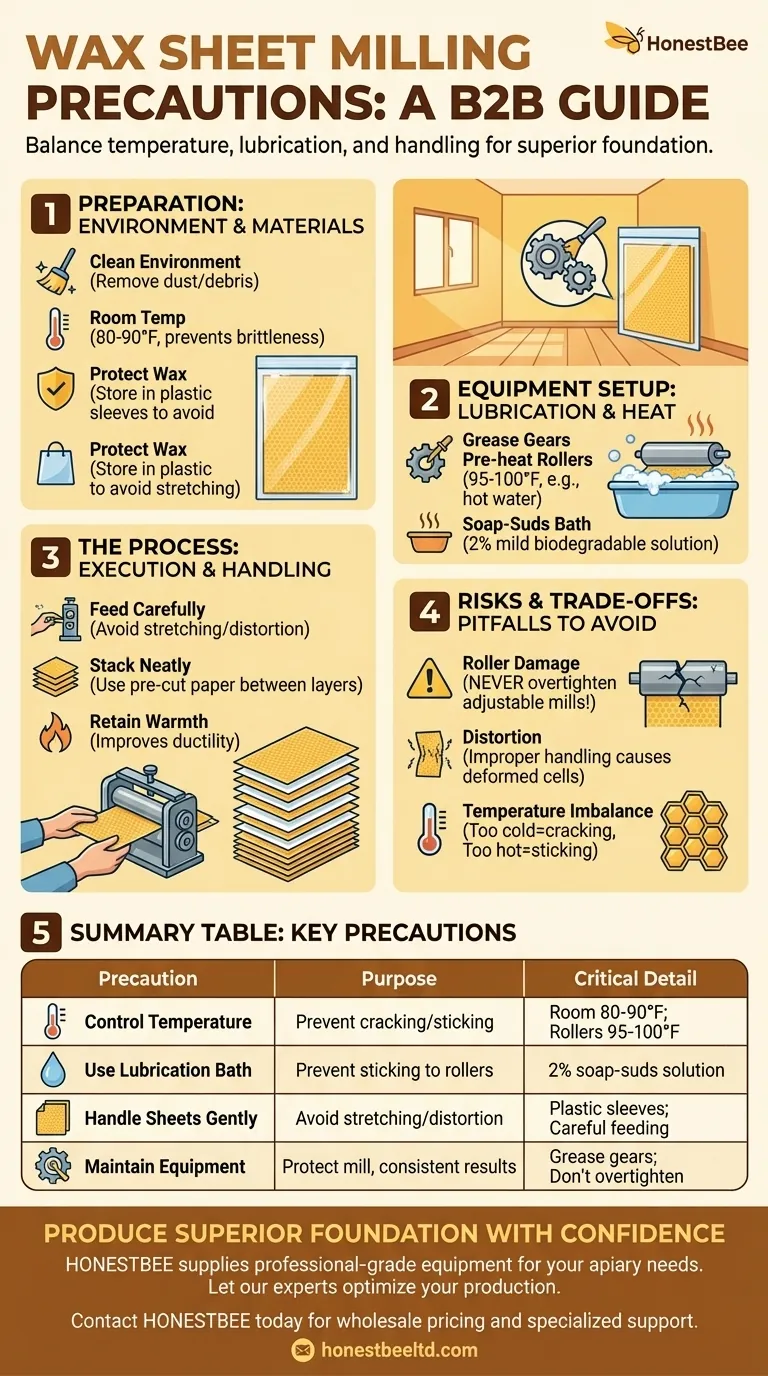

Preparing Your Workspace and Materials

Proper preparation is the foundation for a smooth milling operation. Neglecting this stage introduces variables that can lead to poor quality and frustration.

Ensure a Clean Environment

Your milling area must be meticulously clean. Any dust, debris, or foreign particles can become permanently embedded in the wax sheets, compromising the final product.

Control Room Temperature

The room where you are milling should be heated to at least 80°F, with 90°F being preferable. This prevents the wax sheets from cooling too quickly as they are processed, which would make them brittle and prone to cracking.

Prepare the Wax Sheets

To prevent stretching and distortion of the cell size before milling, store and handle your smooth wax sheets in a plastic sleeve. Some processes may also involve soaking the sheets in a briny water bath after initial decontamination.

Setting Up the Milling Equipment

Your mill is a precision tool. Proper setup and maintenance are critical to protect your investment and ensure consistent results.

Lubricate the Mill Gears

The gears of the mill must be greased often. Use a heavy gear grease to keep them running tightly, which reduces wear and maintains the precise alignment of the rollers.

Pre-heat the Rollers

The mill rollers themselves must be pre-heated to between 95°F and 100°F. You can achieve this by carefully pouring boiling water over them or by using a heating pad. This ensures the wax flows into the embossing pattern correctly rather than cracking.

Prepare the Lubrication Bath

A water bath containing a 2% solution of mild, biodegradable soap-suds is essential. This solution serves two purposes: it prevents the warm wax from sticking to the rollers and it helps "season" the mill's surface for future use.

The Milling Process: Executing with Precision

With everything prepared, the focus shifts to careful and consistent execution. Your technique during the milling process directly impacts the quality of the foundation.

Feed the Wax Sheets Carefully

Handle the sheets gently as you feed them into the mill. The goal is to avoid any stretching, which would distort the final cell dimensions and weaken the foundation.

Handle Embossed Sheets Correctly

As the embossed foundation sheets exit the mill, stack them neatly on a flat board or plate. Place a sheet of pre-cut paper between each layer of wax to prevent them from sticking together as they cool.

Neat stacks also retain warmth more effectively. This residual heat improves the ductility of the foundation, making it less brittle and easier to handle or install in frames later.

Understanding the Risks and Trade-offs

Milling wax is not without its pitfalls. Understanding these risks is key to avoiding costly mistakes and equipment damage.

The Risk of Roller Damage

If you are using an adjustable mill, never screw the rollers down too tightly. Applying excessive pressure can permanently damage the embossing heads, ruining the mill's ability to produce a correct cell pattern.

The Problem of Distortion

The most common quality issue is foundation that is stretched or distorted. This is caused by improper handling before or during milling. Distorted cells will not be accepted as readily by the bees, defeating the purpose of creating foundation.

Temperature Imbalance

Temperature is a constant balancing act. If the room or rollers are too cold, the wax will be brittle and crack. If they are too hot, the wax will be overly soft, stick to the rollers despite lubrication, and easily lose its shape.

Making the Right Choice for Your Goal

Your approach should be guided by your primary objective. Use these guidelines to focus your efforts.

- If your primary focus is producing high-quality foundation: Your top priority is meticulous temperature control of both the room and the rollers, combined with careful handling to prevent stretching.

- If your primary focus is protecting your equipment investment: Pay close attention to regular gear lubrication and, above all, avoid overtightening the rollers on an adjustable mill.

By managing these critical variables, you can consistently produce high-quality foundation while protecting your valuable equipment.

Summary Table:

| Key Precaution | Purpose | Critical Detail |

|---|---|---|

| Control Temperature | Prevent wax from cracking or sticking | Heat room to 80-90°F; pre-heat rollers to 95-100°F |

| Use Lubrication Bath | Prevent wax from sticking to rollers | Use a 2% solution of mild, biodegradable soap-suds |

| Handle Sheets Gently | Avoid stretching and cell distortion | Handle sheets in plastic sleeves; feed carefully into mill |

| Maintain Equipment | Protect mill and ensure consistent results | Grease gears often; never overtighten adjustable rollers |

Produce Superior Foundation with Confidence

Mastering the milling process is essential for commercial apiaries and distributors who demand high-quality, durable wax foundation that bees readily accept. HONESTBEE supplies the professional-grade beekeeping equipment and supplies needed to achieve these precise results.

Let our experts help you select the right mills and accessories to optimize your foundation production. Contact HONESTBEE today for wholesale pricing and specialized support for your operation.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

People Also Ask

- What is the primary function of a wax printer in beekeeping? Optimize Hive Energy and Boost Honey Yields

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency

- What is the specific function of a casting mold in beeswax foundation? Boost Efficiency with Precision Patterns

- What is the primary function of high-precision foundation rollers? Achieve Perfect Beeswax Texture & Hive Stability

- What is a fully automatic wax foundation machine used for? Maximize Hive Productivity & Honey Yield

- What is the purpose of a Metal Casting Mold? Boost Honey Yield with Precise Beeswax Foundation Sheets

- What happens to the beeswax sheet after it has been flattened and embossed? Essential Steps for Structural Integrity

- How does beeswax contribute to the technical output and economic value? Unlock New Revenue Streams with Processing