The primary cost-saving benefit of a fully automatic wax foundation machine is the significant reduction in direct labor costs. By automating the entire production process, these machines eliminate the need for constant human supervision and manual intervention, allowing for continuous, high-volume output with minimal staff.

The decision to invest in a fully automatic machine is an economic one. It involves trading a high initial capital expenditure for substantial long-term savings in labor, increased production efficiency, and reduced material waste.

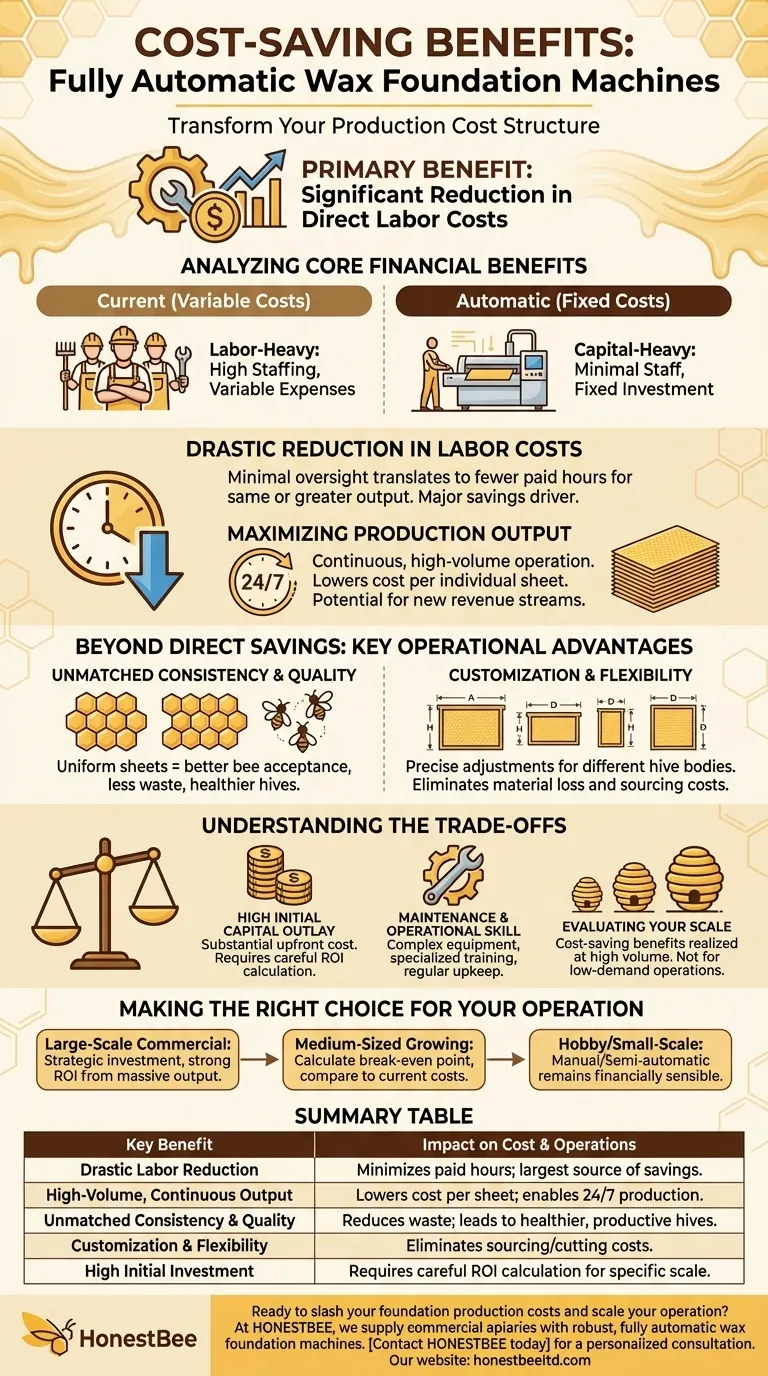

Analyzing the Core Financial Benefits

The financial case for an automatic machine rests on its ability to fundamentally change your production cost structure from variable (labor-heavy) to fixed (capital-heavy).

Drastic Reduction in Labor Costs

A fully automatic machine operates with minimal human oversight. This directly translates to fewer paid hours required to produce the same, or even a greater, number of foundation sheets compared to manual or semi-automatic methods.

This reduction is the single most significant driver of cost savings, especially in regions with high labor costs.

Maximizing Production Output

These machines are designed for continuous operation, enabling you to produce foundation sheets 24/7 if necessary. This high-volume capability drastically lowers the cost per individual sheet.

By maximizing output, you can meet large-scale demands internally or even create a new revenue stream by selling excess foundation to other beekeepers.

Beyond Direct Savings: Key Operational Advantages

While direct cost reduction is compelling, the operational benefits also contribute to a stronger financial position over time.

Unmatched Consistency and Quality

Automation ensures that every sheet is produced to the exact same specifications. This uniformity leads to better acceptance by bees, more consistent comb construction, and fewer rejected or wasted sheets.

High-quality foundation contributes to healthier, more productive hives, which is an indirect but valuable economic benefit.

Customization and Flexibility

Modern automatic machines allow for precise adjustments to sheet dimensions. You can tailor foundation for different hive bodies, nucs, or specific beekeeping practices without waste.

This eliminates the costs associated with sourcing multiple sizes of foundation or the labor and material loss involved in cutting down standard sheets.

Understanding the Trade-offs

A balanced assessment requires acknowledging the significant initial investment and ongoing operational considerations. An automatic machine is not the right choice for every operation.

The High Initial Capital Outlay

The primary drawback is the substantial upfront cost. This investment can be prohibitive for smaller operations and requires careful financial planning and a clear return on investment (ROI) calculation.

Maintenance and Operational Skill

These are complex pieces of equipment that require regular maintenance to perform optimally. Operators may also need specialized training to run and troubleshoot the machine effectively, which represents an additional time and cost factor.

Evaluating Your Scale of Operation

The cost-saving benefits are only realized at a certain production volume. If your need for foundation is relatively low, the machine may sit idle, making it impossible to recoup the initial investment.

Making the Right Choice for Your Operation

To determine if this investment is right for you, analyze your decision based on the scale and goals of your beekeeping operation.

- If your primary focus is large-scale commercial production: A fully automatic machine is a strategic investment that will almost certainly provide a strong ROI through labor savings and massive output.

- If your primary focus is a medium-sized, growing operation: Carefully calculate your break-even point by comparing the machine's cost against your current annual labor and foundation purchasing expenses.

- If your primary focus is hobby or small-scale beekeeping: Manual or semi-automatic methods remain the most financially sensible and practical solution for your needs.

Ultimately, the right machine is the one that aligns with the specific economic realities of your beekeeping enterprise.

Summary Table:

| Key Benefit | Impact on Cost & Operations |

|---|---|

| Drastic Labor Reduction | Minimizes paid hours; largest source of savings, especially in high labor-cost regions. |

| High-Volume, Continuous Output | Lowers cost per sheet; enables 24/7 production to meet large demands or create new revenue. |

| Unmatched Consistency & Quality | Reduces material waste from rejected sheets; leads to healthier, more productive hives. |

| Customization & Flexibility | Eliminates costs of sourcing multiple foundation sizes or labor involved in manual cutting. |

| High Initial Investment | Significant upfront capital outlay requires careful ROI calculation for your specific scale. |

Ready to slash your foundation production costs and scale your operation?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, fully automatic wax foundation machines designed for high-volume, cost-effective production. Our experts can help you calculate your specific ROI and select the perfect machine to transform your cost structure.

Contact HONESTBEE today for a personalized consultation and discover how automation can strengthen your bottom line.

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- What miscellaneous equipment is useful when making beeswax foundation? Essential Support Tools for Beekeepers

- What are the key features of the beeswax foundation machine's mold surface? Non-Stick, Durable & Precise

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- How do fully automatic wax foundation machines benefit beekeepers? Boost Efficiency & Scale Your Apiary

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency