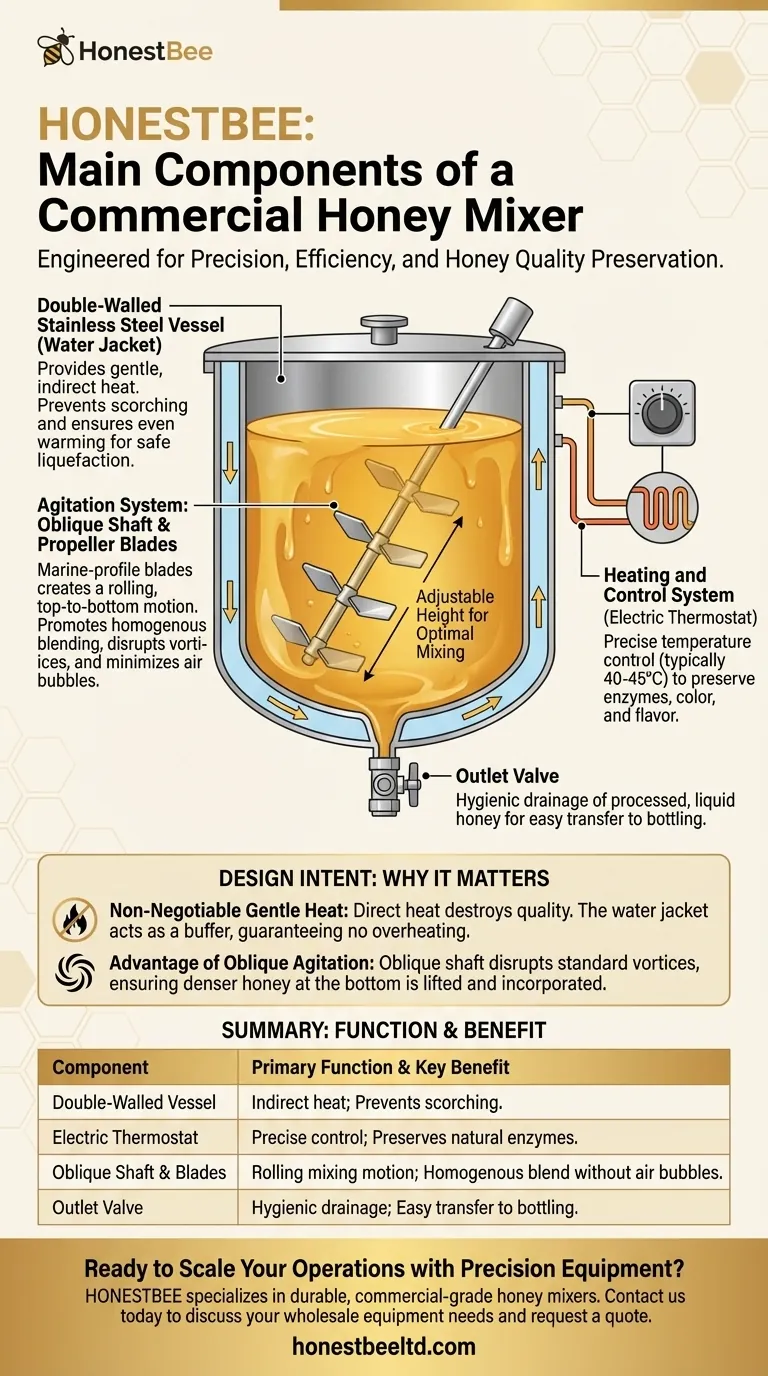

A honey mixer is a specialized piece of equipment built from several distinct components working in unison. Its core elements include a double-walled stainless steel vessel that acts as a water jacket, an electric thermostat for heating, and a unique mixing assembly featuring an oblique shaft with adjustable, propeller-style blades.

The design of a honey mixer is not just about stirring. Each component is engineered to gently liquefy and blend honey by applying controlled, indirect heat while ensuring a thorough mix, all to preserve the honey's natural quality.

The Core Components and Their Purpose

To understand how a honey mixer functions, it's essential to look at how each part contributes to the overall goal of processing honey without degrading it.

The Double-Walled Vessel

The main body of the mixer is a double-walled cylindrical vessel, almost always made of food-grade stainless steel for hygiene and durability.

This design creates a sealed cavity, or "jacket," around the inner container that holds the honey. This cavity is filled with water.

The purpose of this water jacket is to provide gentle and indirect heat. It prevents hot spots that would scorch and damage the honey, ensuring the entire batch is warmed evenly.

The Heating and Control System

An electric resistance thermostat is used to heat the water within the vessel's outer wall.

This component is critical for precise temperature control. Honey is sensitive to high temperatures, which can destroy its beneficial enzymes, darken its color, and alter its flavor.

The thermostat allows the operator to heat the honey just enough to make it fluid for mixing and bottling—typically not exceeding 40-45°C (104-113°F)—thereby preserving its natural characteristics.

The Agitation System: Shaft and Blades

The mixing action is performed by blades with a marine propeller profile attached to a shaft.

This propeller design is specifically chosen for its efficiency in moving viscous liquids like honey. It creates a strong flow that blends the honey thoroughly while minimizing the introduction of air bubbles.

The shaft holding the blades is mounted at an oblique angle, not vertically. This angled placement creates a more complex and effective mixing pattern, ensuring a rolling motion that circulates the entire batch from top to bottom.

Furthermore, the blades are often adjustable in height along the shaft. This allows the operator to position them optimally for different batch sizes or to target dense areas of crystallized honey at the bottom of the tank.

The Outlet Valve

A drain hole and valve are located at the bottom of the vessel. This provides a simple and hygienic way to empty the processed, liquid honey from the mixer into storage or bottling equipment.

Understanding the Design's Intent

The specific combination of these components is deliberate and designed to overcome the challenges of working with honey. A simple heated pot with a standard stirrer would not suffice.

Why Gentle Heat is Non-Negotiable

Direct heat, like placing a pot on a burner, is too aggressive for honey. It would inevitably create localized hot spots, caramelizing sugars and destroying the delicate enzymes and aromatic compounds that define high-quality honey.

The water jacket acts as a buffer, guaranteeing that no part of the honey is exposed to temperatures higher than that of the circulating water.

The Advantage of Oblique Agitation

A standard vertical agitator often creates a vortex, pulling air into the mixture and potentially leaving unmixed "dead zones" at the bottom corners of the tank.

The oblique shaft disrupts this vortex, promoting a powerful top-to-bottom turnover. This ensures that denser, crystallized honey at the bottom is lifted and incorporated into the rest of the batch, resulting in a perfectly homogenous product.

How This Applies to Your Goal

Understanding these components helps you appreciate what the equipment is designed to achieve for your final product.

- If your primary focus is decrystallizing honey: The heated water jacket is your most important feature, as it safely liquefies crystals without damaging the product.

- If your primary focus is blending different honey varieties: The oblique shaft and propeller blades are critical for ensuring a completely uniform mix of colors, flavors, and textures.

- If your primary focus is preserving raw honey quality: The thermostat is the key component, as precise, low-temperature control is the only way to maintain the honey's natural enzymes and delicate aroma.

Ultimately, every part of a honey mixer is engineered to treat this valuable product with the specific care it requires.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Double-Walled Vessel | Provides indirect, gentle heat via a water jacket. | Prevents scorching and ensures even warming. |

| Electric Thermostat | Precisely controls the water temperature. | Preserves honey's natural enzymes and flavor. |

| Oblique Shaft & Blades | Creates a rolling, top-to-bottom mixing motion. | Ensures a homogenous blend without air bubbles. |

| Outlet Valve | Allows for hygienic drainage of processed honey. | Facilitates easy transfer to bottling equipment. |

Ready to Preserve Your Honey's Quality with Precision Equipment?

As HONESTBEE, we specialize in supplying durable, commercial-grade honey mixers and other essential beekeeping supplies to commercial apiaries and distributors. Our equipment is designed to meet the exacting standards of professional honey processing, ensuring efficiency and product integrity.

Let us help you scale your operations with reliable wholesale solutions. Contact our team today to discuss your equipment needs and request a quote.

Visual Guide

Related Products

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What are the processing advantages of producing Cream Honey? Turn High-Glucose Varieties into Smooth Premium Products

- How does an industrial high-power stirring machine with a flat grid impeller facilitate honey refining? Expert Guide

- Why is an industrial-grade electric mixer necessary when formulating fortified nutritional candy? Ensure Precise Dosing

- Why are high-precision refrigeration systems or cold rooms necessary in the production cycle of creamed honey?

- Why are industrial stirring and mixing machines essential for algae bee pollen substitutes? Ensure Hive Nutrition

- How does a high-torque mechanical stirrer facilitate the nucleation process in honey? Optimize Your Creaming Efficiency

- Why is vacuum homogenization and stirring equipment critical for manufacturing fortified honey? Enhance Honey Potency

- What role do high-precision scales play in creamed honey quality? Ensure Batch Consistency & Yield