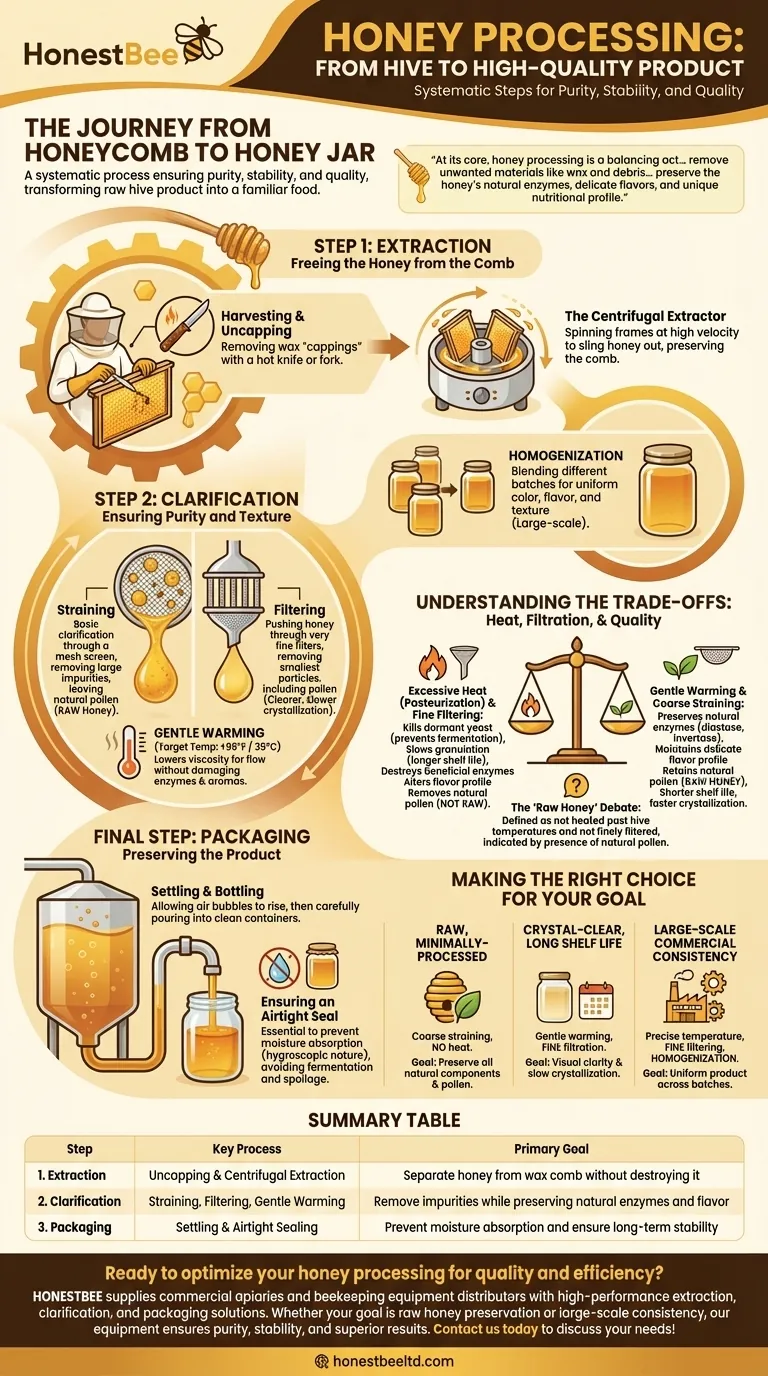

The journey from honeycomb to honey jar is a systematic process designed to ensure purity, stability, and quality. The essential steps involve extracting the honey from the wax comb, clarifying it through filtration to remove impurities, and finally, packaging it into airtight containers for distribution and sale. Each stage plays a critical role in transforming the raw product from the hive into the familiar food we enjoy.

At its core, honey processing is a balancing act. The goal is to remove unwanted materials like wax and debris and ensure a stable, long-lasting product, all while striving to preserve the honey's natural enzymes, delicate flavors, and unique nutritional profile.

Step 1: Extraction - Freeing the Honey from the Comb

The first physical step after removing honey frames from the hive is to separate the liquid honey from the beeswax structure that holds it.

Harvesting and Uncapping

Before extraction can begin, beekeepers carefully remove the thin layer of beeswax, known as "cappings," that bees build to seal the honey-filled cells. This is typically done with a specialized hot knife or an uncapping fork.

The Role of the Centrifugal Extractor

Once uncapped, the frames are placed inside a honey extractor. This device uses centrifugal force, spinning the frames at a high velocity to sling the honey out of the comb cells without destroying the comb itself, which can often be returned to the hive.

Step 2: Clarification - Ensuring Purity and Texture

After extraction, the raw honey contains various particles, including bits of beeswax, pollen, and other hive debris. The clarification stage cleans the honey and prepares it for bottling.

Straining vs. Filtering: A Critical Distinction

Straining is the most basic form of clarification, where honey is passed through a mesh screen to remove large, visible impurities. This is common for "raw" honey, as it leaves natural pollen grains intact.

Filtering, on the other hand, can involve pushing honey under pressure through very fine filters. This process removes even the smallest particles, including pollen, resulting in a perfectly clear, liquid product that is slower to crystallize.

The Purpose of Gentle Warming

To make honey flow more easily for straining or filtering, processors often warm it gently. This temporarily lowers the honey's viscosity. The key is to keep the temperature low to avoid damaging the delicate enzymes and aromas that define the honey's quality.

Homogenization for Batch Consistency

In large-scale commercial operations, honey from different hives or apiaries may be blended. Homogenization is a process that ensures every jar from that batch has a uniform color, flavor, and texture. This step is rarely used by small-scale producers.

Understanding the Trade-offs: Heat, Filtration, and Quality

The methods used during clarification are the most significant factor in determining the final character of the honey. Understanding these trade-offs is crucial for both producers and consumers.

The Impact of Excessive Heat

While gentle warming is beneficial, excessive heat (pasteurization) fundamentally changes the honey. High temperatures can destroy beneficial enzymes like diastase and invertase and can alter the delicate flavor profile, effectively "cooking" the honey.

The "Raw Honey" Debate

The definition of "raw honey" typically means the honey has not been heated past hive temperatures (around 95°F or 35°C) and has not been finely filtered. The presence of natural pollen is a key marker, which is why ultra-filtered honey is not considered raw.

Balancing Shelf Life and Natural State

Processing offers clear benefits. Heating and fine-filtering can kill dormant yeast cells, preventing fermentation. It also significantly slows down granulation (crystallization), resulting in a product that remains liquid on the shelf for much longer, which many consumers prefer.

Final Step: Packaging - Preserving the Product

The last step is to transfer the processed honey into clean, food-safe containers.

Settling and Bottling

Before bottling, honey is often left in a tank to allow air bubbles introduced during processing to rise to the surface. It is then carefully poured into jars or bottles.

Ensuring an Airtight Seal

Honey is hygroscopic, meaning it readily absorbs moisture from the air. A proper, airtight seal is essential to prevent this, as excess moisture can lead to fermentation and spoilage over time.

Making the Right Choice for Your Goal

The ideal processing method depends entirely on the desired outcome for the final product.

- If your primary focus is raw, minimally-processed honey: Rely on coarse straining without any heat to preserve all natural components and pollen.

- If your primary focus is a crystal-clear product with a long shelf life: Employ gentle warming and fine filtration to achieve visual clarity and slow down crystallization.

- If your primary focus is large-scale commercial consistency: Incorporate precise temperature controls, fine filtering, and homogenization to guarantee a uniform product across all batches.

By understanding the purpose of each step, you can make informed decisions that align with your specific goals for quality, appearance, and shelf life.

Summary Table:

| Step | Key Process | Primary Goal |

|---|---|---|

| 1. Extraction | Uncapping & Centrifugal Extraction | Separate honey from wax comb without destroying it |

| 2. Clarification | Straining, Filtering, Gentle Warming | Remove impurities while preserving natural enzymes and flavor |

| 3. Packaging | Settling & Airtight Sealing | Prevent moisture absorption and ensure long-term stability |

Ready to optimize your honey processing for quality and efficiency? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance extraction, clarification, and packaging solutions through our wholesale-focused operations. Whether your goal is raw honey preservation or large-scale consistency, our equipment ensures purity, stability, and superior results. Contact us today to discuss your needs and discover how we can support your operation!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the characteristics of motors used in honey extractors? Ensure Efficient, Damage-Free Honey Harvesting

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency

- What are some safety tips for using electric honey extractors? Ensure a Smooth, Hazard-Free Harvest

- What is the energy consumption like for automatic honey extractors? Maximize Your Harvest Efficiency

- What is the difference between manual and electric honey extractors? Choose the Right Tool for Your Hive Count