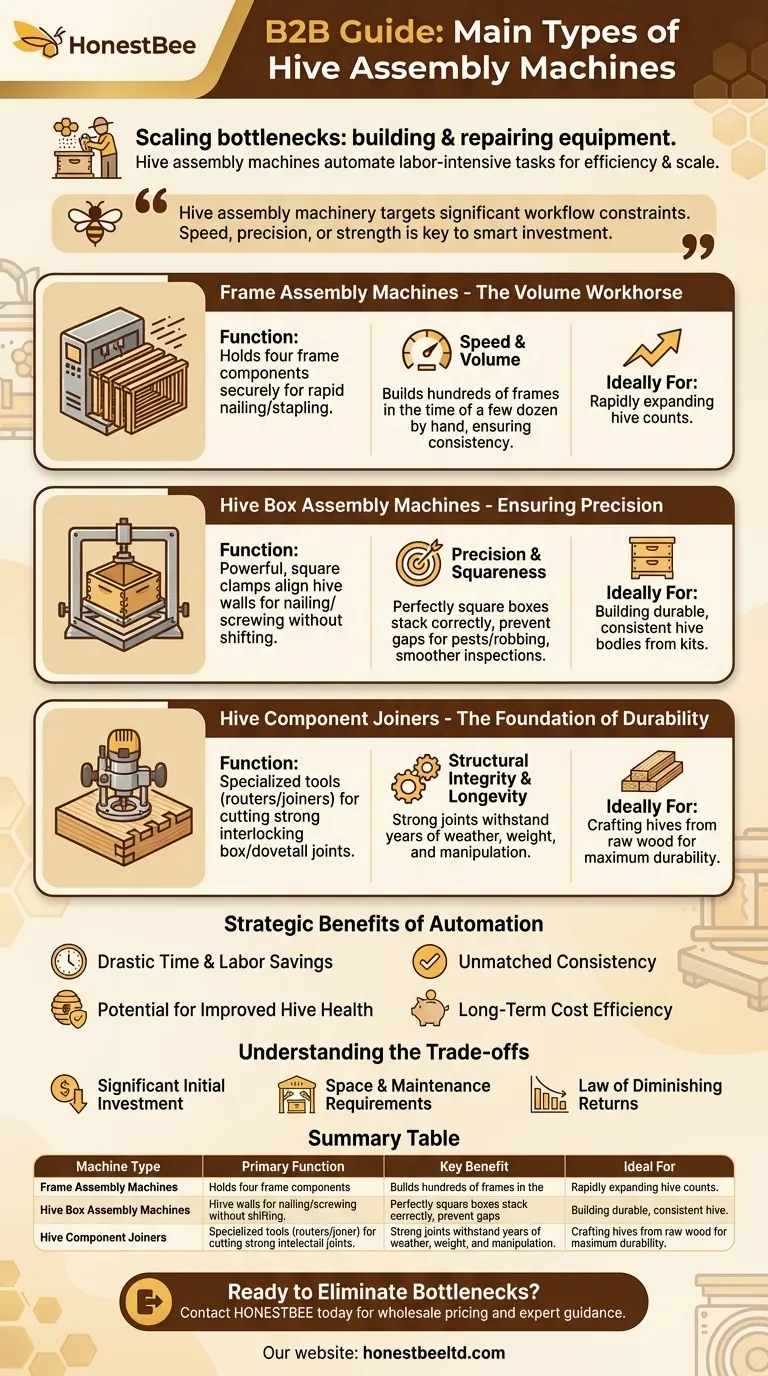

When scaling a beekeeping operation, the most common bottlenecks involve building and repairing equipment. The primary types of hive assembly machines designed to solve this are frame assembly machines, hive box assembly machines, and specialized hive component joiners. Each machine automates a distinct, labor-intensive part of creating a modern beehive.

Hive assembly machinery is about targeting the most significant constraints in your workflow. Understanding the specific function of each machine—speed for frames, precision for boxes, or strength for joints—is the key to making a smart investment that genuinely improves your apiary's efficiency and scale.

The Core Categories of Hive Assembly Machinery

Each type of machine is built to solve a very specific problem. Your choice depends entirely on which task consumes the most time and labor in your operation.

Frame Assembly Machines: The Volume Workhorse

A single hive requires up to ten frames per box, making frame assembly the most repetitive task in beekeeping. A frame assembly machine, or a simpler frame assembly jig, is designed to hold the four wooden components of a frame securely in place for rapid nailing or stapling.

The primary benefit here is speed. These devices allow a beekeeper to build hundreds of frames in the time it might take to build a few dozen by hand, ensuring consistency across every single one.

Hive Box Assembly Machines: Ensuring Precision

Hive box assembly machines are essentially powerful, perfectly square clamps. Their purpose is to hold the four walls of a hive body or super in rigid alignment, allowing you to nail or screw the corners together without any shifting.

The key advantage is precision. A perfectly square box stacks correctly, prevents gaps that allow robbing or pests, and makes hive inspections smoother. This consistency is difficult to achieve by hand, especially when assembling many boxes.

Hive Component Joiners: The Foundation of Durability

This is a more specialized category for those who build hive bodies from raw lumber rather than pre-cut kits. These machines, often routers or dedicated joinery tools, are used to cut the strong, interlocking box joints (or dovetail joints) on the edges of the hive walls.

Their function is to create structural integrity. Strong, tight-fitting joints are the single most important factor in the longevity of a hive box, ensuring it can withstand years of weather, weight, and manipulation.

The Strategic Benefits of Automation

Investing in machinery is about more than just convenience. It introduces several strategic advantages that are critical for growth.

Drastic Time and Labor Savings

This is the most immediate and obvious benefit. Repetitive tasks are completed in a fraction of the time, freeing up valuable labor for more critical apiary management activities like inspections, treatments, and harvesting.

Unmatched Consistency

Machines eliminate human error. Every frame is identical, and every box is perfectly square. This uniformity simplifies management, as all components across all your hives become interchangeable.

Potential for Improved Hive Health

Well-assembled equipment with tight joints and no gaps provides better insulation for the colony. It also reduces crevices where pests like wax moths or small hive beetles can hide, contributing to a healthier hive environment.

Long-Term Cost Efficiency

While there is an upfront cost, the investment pays for itself over time through reduced labor hours and longer-lasting equipment. Durable, well-built hives require fewer repairs and replacements.

Understanding the Trade-offs

Machinery is a powerful tool, but it is not the right solution for every beekeeper. Objectivity is required before making an investment.

Significant Initial Investment

These machines represent a serious capital expense. For a hobbyist with only a handful of hives, the cost is unlikely to be justified by the time saved. Their value is realized at a commercial or serious sideline scale.

Space and Maintenance

Unlike hand tools, assembly machines require a dedicated workshop space. They also have moving parts that need regular cleaning, calibration, and maintenance to function correctly and safely.

The Law of Diminishing Returns

The efficiency gains are most dramatic when moving from a few hives to a few dozen. A beekeeper with two hives will not see a meaningful return on investment from a machine that can assemble fifty boxes per hour.

Making the Right Choice for Your Apiary

Your decision should be based on a clear analysis of the primary bottleneck in your current workflow.

- If your primary focus is rapidly expanding your hive count: A frame assembly machine or jig will deliver the biggest impact by tackling the most numerous and repetitive component.

- If your primary focus is building high-quality, long-lasting hive bodies from kits: A hive box assembly machine is your most valuable tool for ensuring perfect alignment and durability.

- If your primary focus is woodworking and creating hives from raw lumber: A component joiner for cutting box joints is the essential first step for foundational strength and quality.

Ultimately, the right machine is the one that directly solves the most significant constraint on your operation's growth and efficiency.

Summary Table:

| Machine Type | Primary Function | Key Benefit | Ideal For |

|---|---|---|---|

| Frame Assembly Machine | Holds frame parts for fast nailing/stapling | Speed & Volume | Rapidly expanding hive counts |

| Hive Box Assembly Machine | Clamps box walls for perfect alignment | Precision & Squareness | Building durable, consistent hive bodies from kits |

| Hive Component Joiner | Cuts strong box/dovetail joints on lumber | Structural Integrity & Longevity | Crafting hives from raw wood for maximum durability |

Ready to Eliminate Your Beekeeping Equipment Bottlenecks?

As a commercial apiary or beekeeping equipment distributor, your time and efficiency are paramount. HONESTBEE supplies the robust, wholesale-focused hive assembly machinery you need to scale your operation with confidence.

Our equipment is engineered to deliver the drastic time savings, unmatched consistency, and long-term cost efficiency that serious beekeepers depend on. Stop wasting hours on manual assembly and start building a more productive, profitable apiary.

Contact HONESTBEE today for wholesale pricing and expert guidance on the right machinery for your specific workflow.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Professional Engraved Round Hive Number Tags for Beekeeping

People Also Ask

- How does professional beehive manufacturing machinery contribute to the promotion of modern beekeeping models?

- How does the use of specialized hive-making machinery contribute to the modern beekeeping industry? Drive Scalability

- How do professional beekeeping machinery support sustainable management? Boost Ecosystems with Industrial Efficiency

- Why is high-precision woodworking machinery critical for Bee Space? Optimize Hive Manufacturing Efficiency

- What is the advantage of hive component joiners? Boost Efficiency for Commercial Apiaries

- What is the necessity of industrial-grade hive-making machines? Scale Your Commercial Apiary with Precision

- What is the function of Hive Component Joiners? Precision Assembly for Professional Beekeeping Equipment

- Why is a thickness planer necessary for beehive boards? Create Airtight, Professional-Grade Hives with Precision