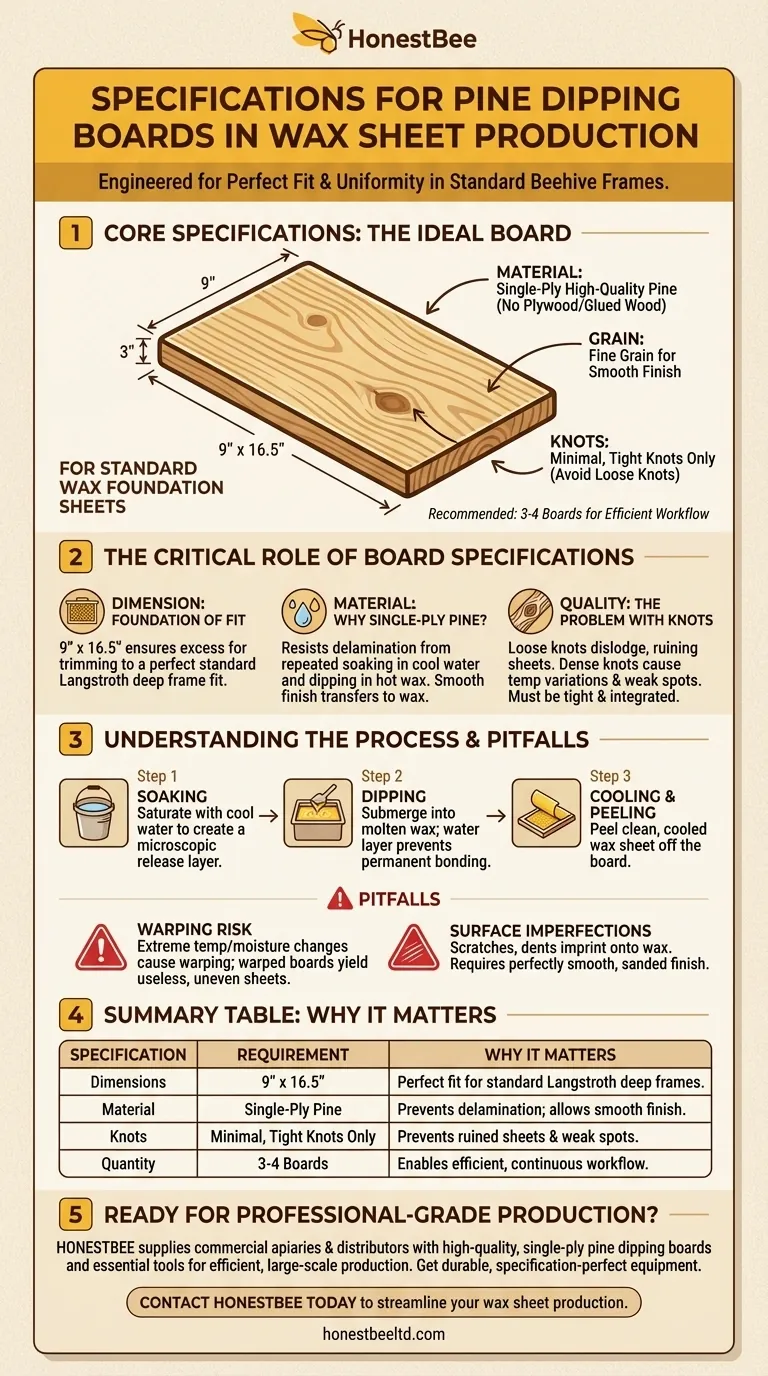

For making standard wax foundation sheets, the ideal dipping board must measure 9" x 16.5" and be crafted from a single piece of high-quality pine. The wood should have as few knots as possible, and any present must be tight, as they can loosen during the production cycle. Having at least three to four of these boards is recommended for an efficient workflow.

The specifications for a dipping board are not arbitrary; they are engineered to ensure the final wax sheet fits a standard beehive frame and possesses a smooth, uniform surface critical for the bees to build upon.

The Critical Role of Board Specifications

A dipping board is more than just a template; it is the primary tool that dictates the quality and usability of your final wax foundation sheet. Each specification serves a distinct, functional purpose in the production process.

Dimension: The Foundation of Fit

The 9" x 16.5" dimension is deliberately chosen. It is slightly larger than a standard Langstroth deep frame, providing enough excess material for trimming the wax sheet to a perfect fit.

Using a board with incorrect dimensions will result in foundation that is either too small to be effective or too large to fit in the frame without excessive, wasteful trimming.

Material: Why Single-Ply Pine?

Pine is the preferred wood due to its fine grain, which allows for a very smooth finish after sanding. This smoothness is transferred directly to the wax sheet.

Using single-ply (a single, solid piece of wood) is non-negotiable. Plywood or glued-together boards will delaminate and fall apart after repeated cycles of soaking in water and dipping into hot wax.

Quality: The Problem with Knots

The ideal board has no knots. Knots are denser than the surrounding wood and can create slight temperature variations during dipping, leading to weak spots or imperfections in the wax.

Most critically, a loose knot can dislodge during the process of soaking or sanding, leaving a hole in the board that will ruin every subsequent wax sheet made with it. If knots are unavoidable, they must be "tight" and fully integrated with the wood grain.

Understanding the Process and Pitfalls

The specifications are designed to withstand the stresses of the dipping process. Understanding this context reveals why shortcuts or low-quality materials will ultimately fail.

The Purpose of Soaking

Before dipping into molten wax, the pine board is soaked in cool water. This water saturation creates a microscopic release layer that prevents the wax from bonding permanently to the wood.

This step is what allows you to peel the finished, cooled wax sheet off the board cleanly.

The Risk of Warping and Imperfections

The board is constantly subjected to extreme temperature and moisture changes. This cycle is what causes wood to warp.

A warped board will not produce a flat, even wax sheet, rendering it useless. This is another reason why a solid, single-ply, high-quality board is essential for longevity and consistent results.

The Necessity of a Smooth Surface

The board must be sanded to a perfectly smooth, glass-like finish. Any scratch, dent, or imperfection on the surface of the wood will be directly imprinted onto the wax foundation.

This requires periodic light sanding between uses to maintain the quality of the board's surface and, by extension, the quality of your wax sheets.

Making the Right Choice for Your Goal

Your approach to sourcing or making your boards should align with your end goal.

- If your primary focus is producing standard Langstroth foundation: Adhere strictly to the 9" x 16.5" dimension, as this is engineered for a perfect fit in deep frames after trimming.

- If your primary focus is creating high-quality, defect-free sheets: Prioritize selecting single-ply pine boards with the fewest knots possible, even if the initial cost is higher.

- If your primary focus is operational efficiency: Prepare at least three to four boards at once so you can cycle them through the soaking, dipping, and cooling process without downtime.

By understanding the principles behind these specifications, you can reliably produce high-quality wax foundation sheets for your hives.

Summary Table:

| Specification | Requirement | Why It Matters |

|---|---|---|

| Dimensions | 9" x 16.5" | Ensures perfect fit for standard Langstroth deep frames after trimming. |

| Material | Single-Ply Pine | Prevents delamination from repeated water/wax cycles; allows for a smooth finish. |

| Knots | Minimal, Tight Knots Only | Loose knots can dislodge and ruin sheets; tight knots prevent weak spots. |

| Quantity | 3-4 Boards | Enables an efficient, continuous dipping and cooling workflow. |

Ready to produce professional-grade wax foundation sheets?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, single-ply pine dipping boards and other essential tools needed for efficient, large-scale production. Our wholesale-focused operations ensure you get durable, specification-perfect equipment that stands up to rigorous use.

Contact HONESTBEE today to discuss your beekeeping supply needs and streamline your wax sheet production.

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

People Also Ask

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- What is the primary function of a beeswax flatting and embossing machine? Optimize Your Foundation Production

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production