The primary importance of soaping rollers during milling is to act as a crucial release agent. This simple step creates a micro-thin, non-stick barrier that prevents wax from adhering to the rollers, ensuring a smooth and uninterrupted operation.

Soaping is not an optional suggestion but a fundamental requirement for operational efficiency. It directly prevents equipment jamming, product defects, and the significant downtime required for cleaning.

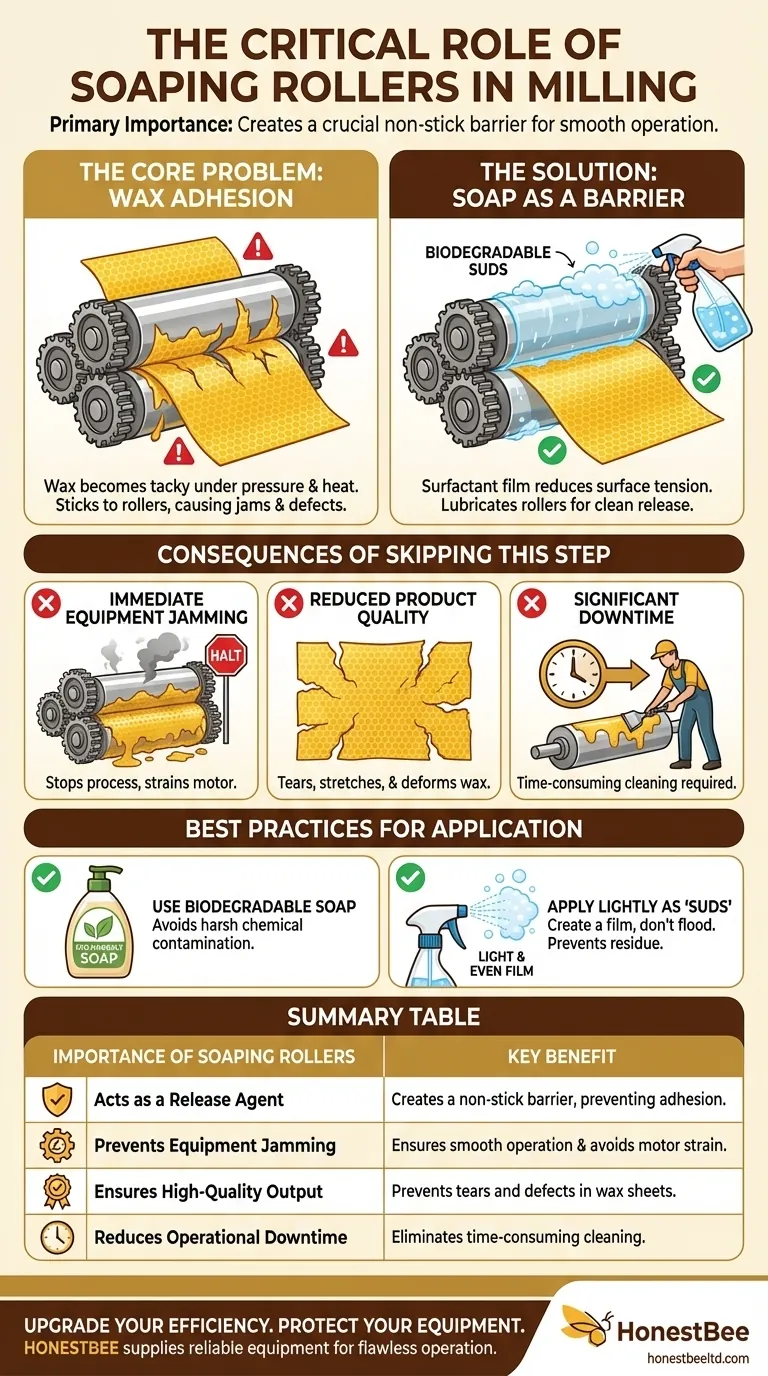

The Core Problem: Wax Adhesion

To understand why soaping is so critical, we must first understand the nature of wax and its interaction with the milling equipment under pressure.

How Soap Acts as a Barrier

Soap functions as a surfactant. When applied as light suds, it creates a microscopic film on the surface of the rollers.

This film drastically reduces the surface tension between the metal roller and the sticky wax. It effectively lubricates the roller, allowing the wax sheet to pass through and receive its impression without bonding to the metal.

Why Wax Sticks

Wax, particularly beeswax, becomes tacky and adhesive when subjected to the pressure and slight friction-generated heat from the milling rollers.

Without a release agent, the wax will naturally try to stick to the roller surface, especially within the fine details of the milling pattern.

The Consequences of Skipping This Step

Failing to soap the rollers introduces immediate and predictable problems into your workflow, turning an efficient process into a frustrating one.

Immediate Equipment Jamming

The most direct consequence is that the wax will stick firmly to the rollers. This can cause the equipment to jam, halting the entire process and potentially straining the motor.

Reduced Product Quality

When wax adheres to the rollers, it can tear, stretch, or deform the sheet being milled. This results in imperfections, unusable products, and wasted material.

Significant Downtime for Cleaning

A roller caked with hardened wax requires a complete shutdown. The cleaning process can be time-consuming and difficult, involving scraping and solvents that add unnecessary labor and delay to your operation.

Best Practices for Application

Properly applying the soap is just as important as using it in the first place. The goal is to create an effective, non-contaminating barrier.

Use a Biodegradable Soap

The references correctly specify using biodegradable soap. This is critical to avoid contaminating the wax with harsh chemicals, which is especially important if the final product is for use in applications like beekeeping.

Apply Lightly as "Suds"

The key is a light and even application. You are creating a film, not flooding the surface. Using "suds" or a very dilute soapy water solution is the ideal method for applying a thin, effective layer without introducing excess moisture or residue.

Making the Right Choice for Your Process

Integrating this step properly is a hallmark of a professional and efficient milling operation. It's a small investment of time that prevents significant problems.

- If your primary focus is equipment longevity and minimal downtime: Make soaping the rollers a mandatory, non-negotiable first step before every single milling session.

- If your primary focus is consistent, high-quality output: Ensure the soap suds are applied lightly and evenly to prevent any wax from tearing or sticking, which guarantees a clean and perfect impression.

Ultimately, this simple preventative measure is the most effective way to ensure a smooth, predictable, and productive workflow.

Summary Table:

| Importance of Soaping Rollers | Key Benefit |

|---|---|

| Acts as a Release Agent | Creates a non-stick barrier, preventing wax adhesion to rollers. |

| Prevents Equipment Jamming | Ensures smooth operation and avoids motor strain. |

| Ensures High-Quality Output | Prevents tears and defects in the wax foundation sheets. |

| Reduces Operational Downtime | Eliminates time-consuming cleaning of wax-caked rollers. |

Upgrade your milling efficiency and protect your equipment. HONESTBEE supplies commercial apiaries and distributors with the reliable beekeeping equipment and supplies needed for a flawless operation. Let our wholesale expertise help you maximize productivity and minimize downtime. Contact our team today to discuss your needs!

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Professional Honey Uncapping Roller for Efficient Harvesting

People Also Ask

- How does beekeeping wax processing equipment improve profitability? Unlock High-Margin Value-Added Revenue

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- Why does the commercial production of beeswax and other honey by-products depend on high-precision equipment?

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- What is the technological significance of the flat plate foundation press? Precision Engineering for Beekeeping Success

- What equipment is needed to manually make wax foundation sheets? Essential Tools for High-Quality Beekeeping Foundation

- What is the primary function of a beeswax flatting and embossing machine? Optimize Your Foundation Production

- What is the design of the beeswax foundation tool and what is its function? Master Manual Foundation Production