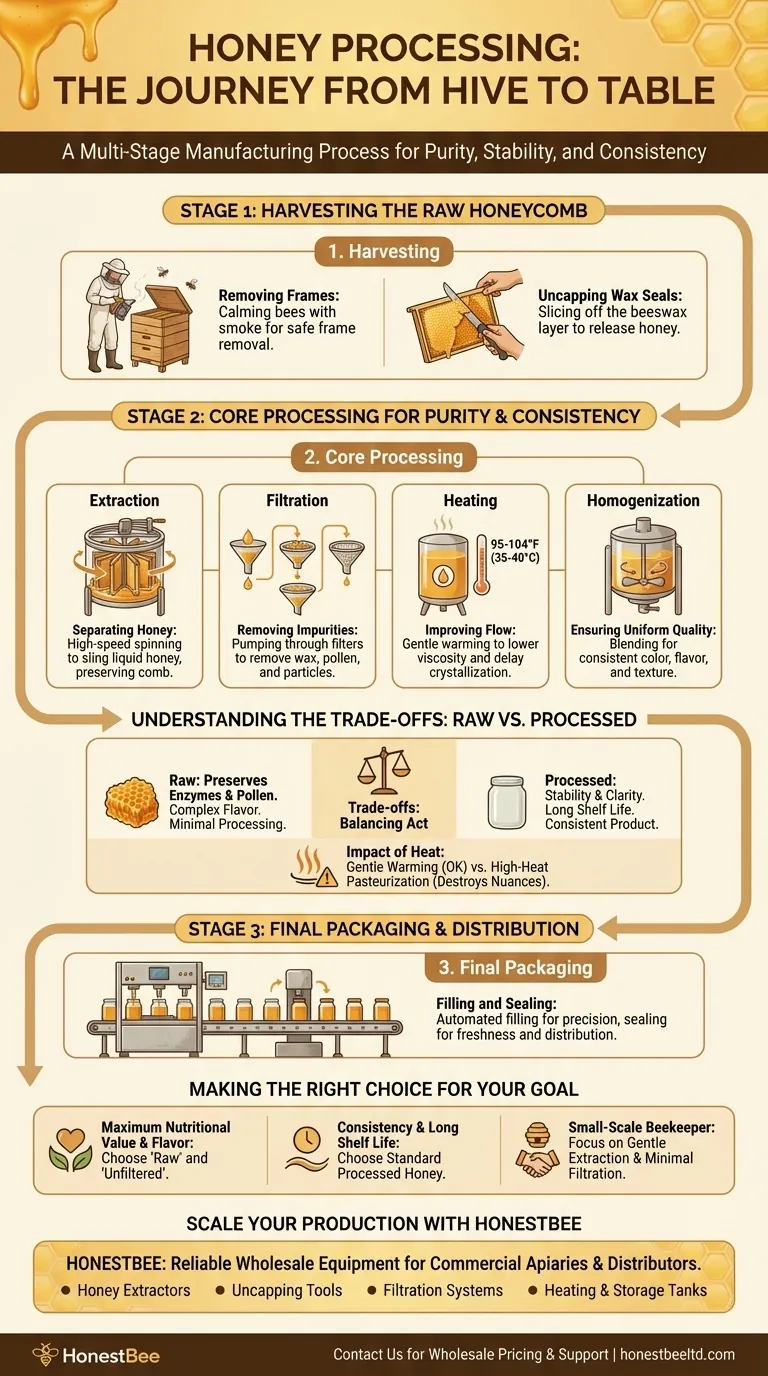

From the hive to your table, the journey of honey involves a multi-stage manufacturing process designed to transform raw honeycomb into a stable, pure, and consistent product. The core steps include harvesting the combs, extracting the liquid honey, filtering out impurities like wax and debris, gently heating it for stability and flow, and finally, packaging it for distribution.

Honey processing is fundamentally a balancing act. The goal is to purify and stabilize the honey for a consistent consumer product, but every step, especially the application of heat and fine filtration, involves a trade-off that can alter it from its natural state.

Stage 1: Harvesting the Raw Honeycomb

The process begins in the field, where beekeepers carefully collect the finished product from the bees. This initial stage requires skill to ensure the hive remains healthy and the honey is collected efficiently.

Removing the Frames

First, beekeepers open the hive. A smoker is often used to puff cool smoke into the hive, which calms the bees and makes them less defensive, allowing for the safe removal of the frames laden with honeycomb.

Uncapping the Wax Seals

Once the frames are removed, you'll see the individual honeycomb cells are sealed with a layer of beeswax. This cap must be removed to release the honey. This is typically done using a heated knife or a specialized uncapping tool that slices off the top layer of wax.

Stage 2: Core Processing for Purity and Consistency

After harvesting, the honeycombs are moved to a processing facility. Here, the focus shifts from collection to refinement, turning the raw, wax-filled comb into the pure liquid honey sold in stores.

Extraction: Separating Honey from the Comb

The uncapped frames are placed inside a honey extractor. This machine uses centrifugal force, spinning the frames at high speed to sling the honey out of the comb, where it collects at the bottom of the drum. This method is highly efficient and keeps the wax comb largely intact for reuse.

Filtration: Removing Impurities

The extracted honey contains particles of beeswax, pollen, and other hive debris. It is pumped through a series of filters to remove these impurities. Coarse filtration removes large particles, while fine filtration can remove even microscopic solids, including pollen.

Heating: Improving Flow and Stability

Raw honey is often thick and can crystallize quickly. To manage this, processors gently heat the honey. This lowers its viscosity, making it flow more easily through filters and pipes. It also helps break down sugar crystals, delaying crystallization and extending shelf life.

Homogenization: Ensuring Uniform Quality

For large-scale operations, honey from many different hives is often blended in large tanks. The homogenization process ensures that every jar in a batch has the same color, texture, flavor, and consistency.

Understanding the Trade-offs: Raw vs. Processed

The decision of how much to process honey is a critical one that directly impacts the final product. There is no single "best" method; it depends entirely on the desired outcome.

The Argument for Processing: Stability and Clarity

Heavily filtered and heated honey has a crystal-clear appearance and a very long shelf life, as crystallization is significantly delayed. This creates a highly consistent product that many consumers have come to expect on supermarket shelves.

The Argument for Raw: Preserving Natural Qualities

Minimal processing, often defined as "raw" and "unfiltered" honey, avoids high heat and fine filtration. This method preserves beneficial enzymes, antioxidants, and the natural pollen content, which many believe contributes to honey's health benefits and complex flavor profile.

The Impact of Heat

This is the most critical trade-off. Gentle warming (to around 95-104°F or 35-40°C) is necessary for easy filtering and bottling. However, high-heat pasteurization can destroy the subtle nuances of flavor and degrade the naturally occurring enzymes that make raw honey unique.

Stage 3: Final Packaging and Distribution

The final step is preparing the honey for the consumer. This stage is crucial for maintaining the quality achieved during processing.

Filling and Sealing

The finished honey is transferred to an automated packaging unit. This machinery efficiently fills jars or other containers to precise levels and seals them to ensure freshness and prevent contamination. From here, the honey is labeled and sent out for distribution.

Making the Right Choice for Your Goal

By understanding the processing journey, you can select the honey that best suits your needs.

- If your primary focus is maximum nutritional value and complex flavor: Seek out honey labeled "raw" and "unfiltered" from local beekeepers or specialty stores.

- If your primary focus is consistency, a long shelf life, and a smooth texture: Standard processed honey is a reliable choice for baking, sweetening drinks, or general use.

- If you are a small-scale beekeeper: Focus on gentle extraction and minimal filtration to preserve the unique character and value of your honey.

Understanding this process empowers you to make an informed choice that aligns with your priorities for flavor, nutrition, and quality.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Harvesting | Uncapping wax seals from honeycomb frames | Release raw honey from the comb |

| 2. Extraction | Using centrifugal force in a honey extractor | Separate liquid honey from wax comb |

| 3. Filtration | Pumping through coarse and fine filters | Remove wax, pollen, and other impurities |

| 4. Heating | Gentle warming (95-104°F / 35-40°C) | Improve flow, delay crystallization, and extend shelf life |

| 5. Packaging | Automated filling and sealing of containers | Ensure product freshness and prepare for distribution |

Scale Your Honey Production with Reliable Equipment

Understanding the honey processing journey is the first step. Executing it efficiently requires durable, high-performance equipment. Whether you're a commercial apiary scaling up operations or a distributor supplying the beekeeping industry, HONESTBEE provides the wholesale-focused solutions you need.

We supply essential beekeeping supplies and equipment, including:

- Honey Extractors for efficient, comb-preserving extraction.

- Uncapping Tools and Knives for precise wax removal.

- Filtration Systems to achieve the desired clarity and purity.

- Heating and Storage Tanks for gentle warming and homogenization.

Let us help you optimize your process for maximum yield and quality. Contact HONESTBEE today for wholesale pricing and expert support tailored to commercial beekeepers and distributors.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently

- What are the three basic types of honey extractors? Choose the Right Tool for Your Apiary

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently

- What is an extractor in beekeeping? Unlock Sustainable Honey Harvesting

- What should be considered when using a honey extractor to avoid damage? Ensure a Smooth, Efficient Harvest