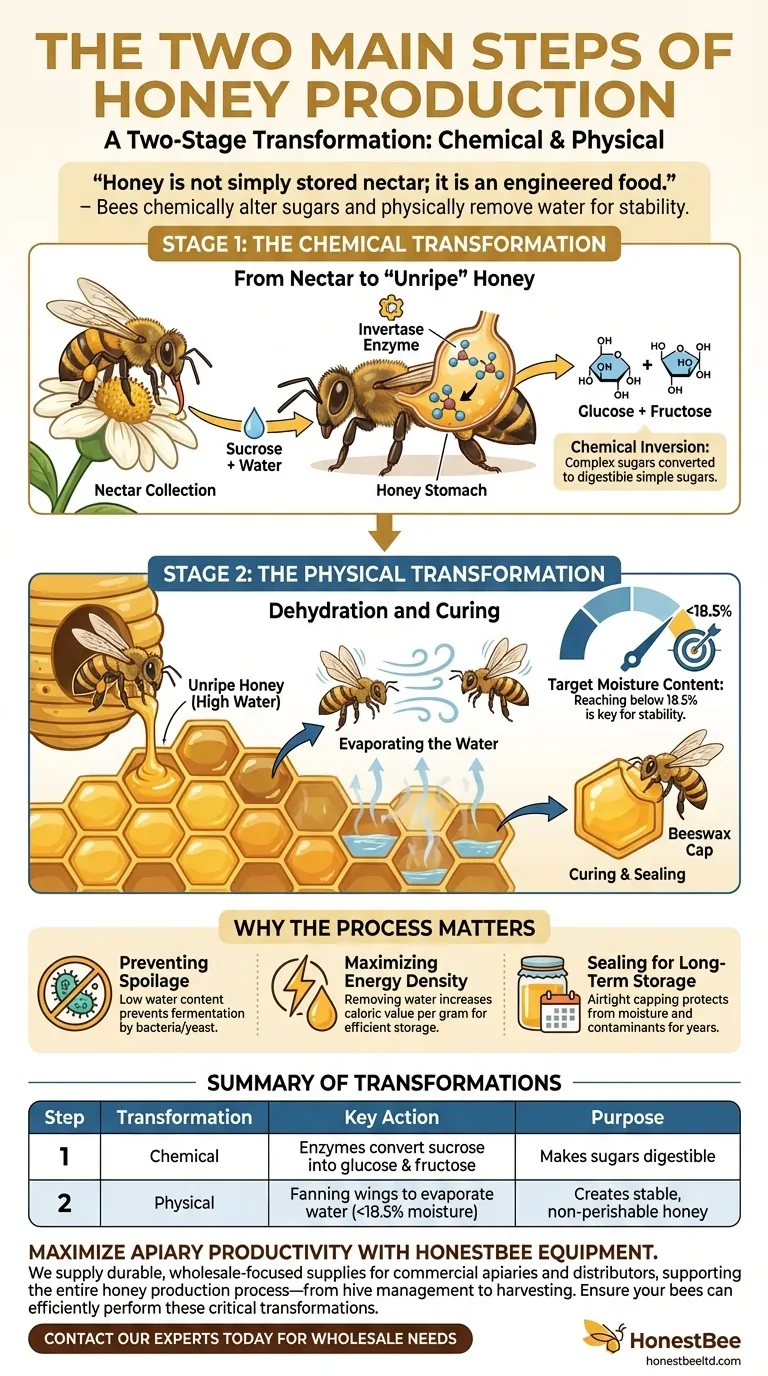

At its core, honey production is a two-stage process of transformation. Bees first perform a crucial chemical transformation, converting raw nectar's complex sugars into simpler ones. They follow this with a physical transformation, dehydrating that solution to create the stable, dense honey that can be stored indefinitely.

Honey is not simply stored nectar; it is an engineered food. Bees chemically alter nectar's sugars for easier digestion and then physically remove most of its water to prevent spoilage, ensuring a stable energy supply for the colony.

The First Transformation: From Nectar to "Unripe" Honey

The first phase of the process begins the moment a bee collects nectar and involves a fundamental chemical change.

Nectar Collection

Foraging worker bees fly from flower to flower, using their long tongues (proboscis) to suck up the sweet liquid nectar. This nectar is primarily composed of sucrose and a high percentage of water.

The Role of the Honey Stomach

The bee stores this nectar in a special organ called the honey stomach, or crop. This is separate from its digestive stomach, ensuring the nectar isn't used for the bee's own energy but is instead transported back to the hive.

Chemical Inversion via Enzymes

Inside the honey stomach, glands secrete an enzyme called invertase. This enzyme immediately begins breaking down the complex sucrose from the nectar into two simpler sugars: glucose and fructose. This process is called inversion.

The Second Transformation: Dehydration and Curing

Once the forager bee returns to the hive, it passes the partially-converted nectar to other worker bees who begin the second phase: removing water to create a stable, finished product.

Depositing the Nectar Solution

House bees take the nectar and deposit it into the hexagonal wax cells of the honeycomb. At this stage, the solution is still very watery and is often referred to as "unripe" honey.

Evaporating the Water

To dehydrate the honey, the bees work together to create airflow. They fan their wings vigorously at the entrance of the hive and throughout its interior, causing the excess water in the nectar solution to evaporate.

Reaching the Target Moisture Content

This fanning process continues until the water content of the honey drops to a specific, critical level—typically below 18.5%. This low moisture content is the key to honey's remarkable stability.

Understanding the Purpose of the Process

These two transformations are not accidental; they are a deliberate strategy for survival. The "why" is just as important as the "how."

Preventing Spoilage

Raw nectar, with its high water content, would quickly ferment and spoil. By reducing the water content to below 18.5% and increasing the sugar concentration, bees create an environment where bacteria and yeast cannot survive. This makes honey one of the most stable natural foods in the world.

Maximizing Energy Density

Removing water also concentrates the sugars, dramatically increasing the caloric value per gram. This creates a highly efficient and energy-dense food source that can sustain the colony through the cold winter months when flowers are not available.

Sealing for Long-Term Storage

Once the honey is fully "cured" with the correct moisture content, the bees cap the cell with a fresh layer of beeswax. This airtight seal protects the finished honey from moisture and contaminants, allowing it to be stored for months or even years.

How to Apply This Knowledge

Understanding this two-stage transformation provides different insights depending on your goal.

- If you are a beekeeper: Your focus is on ensuring bees have sufficient nectar sources and monitoring the hives to harvest only fully capped, low-moisture honey for a stable product.

- If you are a food scientist: The critical insight is that honey's unique properties—its stability and resistance to crystallization—are due to the specific glucose/fructose ratio and low water activity achieved through this process.

- If you are simply curious about nature: The most fascinating aspect is seeing how a collective organism actively engineers its food, turning a perishable liquid into a non-perishable energy source for long-term survival.

Understanding these two transformations reveals honey production not as a simple task, but as a masterpiece of natural chemical and physical engineering.

Summary Table:

| Step | Transformation | Key Action | Purpose |

|---|---|---|---|

| 1 | Chemical | Enzymes convert sucrose into glucose & fructose | Makes sugars digestible |

| 2 | Physical | Fanning wings to evaporate water (<18.5% moisture) | Creates stable, non-perishable honey |

Maximize your apiary's productivity with the right equipment. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed to support the entire honey production process—from hive management to harvesting. Ensure your bees can efficiently perform these critical transformations. Contact our experts today to discuss your wholesale needs!

Visual Guide

Related Products

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Honey Press Wax Press with Tank

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- What other materials can a honey press be used for besides honeycomb? Unlock Multi-Purpose Utility

- How can a honey press be used beyond honey extraction? Unlock Its Full Potential for Your Farm

- Why is the use of standardized honey harvesting tools critical? Enhance Purity and Colony Health in Your Apiary

- How easy is it to clean and maintain the Honey Press? Designed for Quick, Effortless Cleanup