At its core, honey extraction requires three categories of equipment: a tool to uncap the wax-sealed honeycomb, a method to get the honey out of the comb, and a system to filter and bottle the final product. While a beginner can start with simple kitchen tools, dedicated equipment makes the process dramatically more efficient and yields a cleaner result.

The specific equipment you need depends directly on your scale and your goals. The most significant decision is whether you will use a centrifugal extractor to preserve your honeycomb for the bees to reuse, or use a simpler "crush and strain" method which destroys the comb.

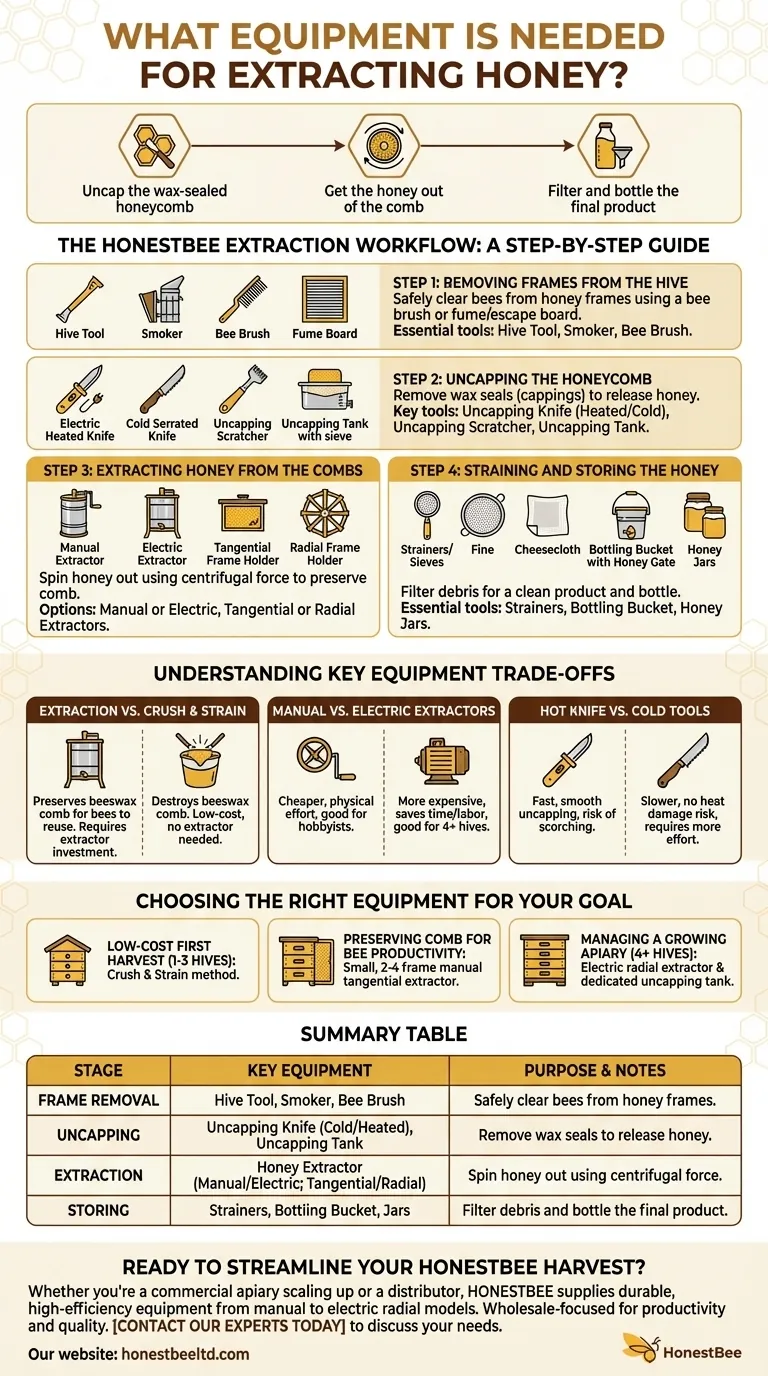

The Honey Extraction Workflow: A Step-by-Step Equipment Guide

The process of extracting honey can be broken down into four distinct stages, each with its own set of essential tools.

Step 1: Removing Honey Frames from the Hive

Before you can extract, you must safely remove the frames of honey from the hive and clear them of bees.

You will need a standard hive tool and smoker, but the key tool for this step is a bee brush. This soft-bristled brush is used to gently sweep the remaining bees off the comb without harming them.

Alternatively, some beekeepers use a fume board or an escape board to clear the honey supers of bees a day before removal, reducing the need for extensive brushing.

Step 2: Uncapping the Honeycomb

The bees seal each cell of honey with a layer of beeswax, called cappings. This must be removed to release the honey.

The primary tool here is an uncapping knife. These can be "cold" serrated knives or, for faster work, electric heated knives that slice through the wax with ease.

For any missed spots or uneven areas of the comb, an uncapping scratcher or fork is used to pierce the remaining cappings.

You will also need an uncapping tank or a simple food-grade bucket with a sieve to catch the wax cappings. This allows the honey that sticks to the cappings to slowly drain and be collected.

Step 3: Extracting Honey from the Combs

This is the central step where honey is removed from the frames. The most common tool is a honey extractor.

A honey extractor is a drum that uses centrifugal force to spin the honey out of the open cells while leaving the delicate wax comb intact. They come in two main varieties: manual (hand-crank) and motorized (electric).

Extractors are also categorized by how they hold the frames. Tangential extractors hold frames like spokes in a wheel and require you to flip them halfway through, while radial extractors hold frames facing outwards and extract from both sides at once.

Step 4: Straining and Storing the Honey

Raw honey coming out of the extractor contains small bits of beeswax, pollen, and other hive debris. This needs to be filtered for a clean, clear final product.

A system of strainers or sieves is used. These are often designed to fit directly on top of a collection bucket and come in coarse and fine grades. Some beekeepers also use cheesecloth as a final filter.

The filtered honey is collected in a bottling bucket. This is a food-grade bucket equipped with a honey gate—a simple valve at the bottom that allows for easy, mess-free filling of jars and containers. Finally, you need your honey jars and lids for storage.

Understanding the Key Equipment Trade-offs

Your choice of equipment involves balancing cost, efficiency, and your long-term beekeeping philosophy.

Extraction vs. Crush and Strain Method

The biggest decision is whether to invest in an extractor. The alternative is the crush and strain method, where you simply crush the entire honeycomb and let the honey strain out through a filter.

This method requires no extractor, making it very low-cost for a first-time harvest. However, it destroys the beeswax comb, forcing the bees to expend significant energy rebuilding it from scratch instead of making more honey.

Manual vs. Electric Extractors

For those who choose extraction, the next choice is power. Manual extractors are cheaper and simpler, making them ideal for hobbyists with only a few hives. They require physical effort to crank.

Electric extractors are more expensive but save significant time and labor, especially when processing honey from four or more hives. They offer consistent speed for more efficient extraction.

Hot Knife vs. Cold Tools

An electric heated knife makes uncapping fast and smooth. However, there is a small risk of scorching the honey if you move too slowly, which can alter its flavor.

A cold serrated knife or uncapping scratcher eliminates any risk of heat damage but is slower and requires more physical effort to slice through the wax cappings.

Choosing the Right Equipment for Your Goal

Select your gear based on the size of your apiary and your long-term priorities.

- If your primary focus is a low-cost first harvest (1-3 hives): Start with the crush and strain method using a bucket, a tool to crush the comb, and a good set of strainers.

- If your primary focus is preserving comb for bee productivity: A small, 2- or 4-frame manual tangential extractor is your most important investment.

- If you are managing a growing apiary (4+ hives): An electric radial extractor and a dedicated uncapping tank will save you an immense amount of time and labor.

Ultimately, investing in the right equipment transforms honey extraction from a laborious chore into a rewarding part of the beekeeping journey.

Summary Table:

| Stage | Key Equipment | Purpose & Notes |

|---|---|---|

| Frame Removal | Hive Tool, Smoker, Bee Brush | Safely clear bees from honey frames. |

| Uncapping | Uncapping Knife (Cold/Heated), Uncapping Tank | Remove wax seals to release honey. |

| Extraction | Honey Extractor (Manual/Electric; Tangential/Radial) | Spin honey out using centrifugal force. |

| Storing | Strainers, Bottling Bucket with Honey Gate, Jars | Filter debris and bottle the final product. |

Ready to streamline your honey harvest?

Whether you're a commercial apiary scaling up or a distributor stocking for the season, HONESTBEE supplies the durable, high-efficiency equipment you need—from manual extractors for small batches to electric radial models for large-scale operations. Our wholesale-focused operations ensure you get the right gear to maximize productivity and honey quality.

Contact our experts today to discuss your specific needs and get a quote tailored to your operation.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What speed should a honey extractor be? Master the RPM Range for Safe, Efficient Extraction

- Why is the width of iron rings varied for radial honey extractor tilt? Optimize Your Harvest with Precise Engineering

- Why is specialized extraction equipment necessary? Maximize Honey Purity, Scale Production, and Meet Export Standards

- How much honey does a beekeeper extract from a hive? Balancing Colony Health with Sustainable Yields

- What are the core advantages of centrifugal automatic honey extractors? Maximize Yield and Preserve Your Honeycomb

- What are the technical advantages of using a centrifuge for honey extraction? Maximize Yield & Preserve Comb Quality

- What are the key considerations for the extraction location? Secure Your Honey Harvest with the Perfect Setup

- Why use a honey extractor? Boost Apiary Health & Harvest Efficiency