In beekeeping, a plastic foundation sheet is a rigid, man-made guide inserted into a hive frame to provide a stable base for bees to build their honeycomb. It is an alternative to traditional beeswax foundation and is typically made from food-grade plastic imprinted with a hexagonal cell pattern, which encourages the bees to build straight, uniform comb.

The core concept is simple: plastic foundation offers superior durability and reusability compared to traditional wax, but it requires a coating of beeswax to ensure the bees will accept and build upon it.

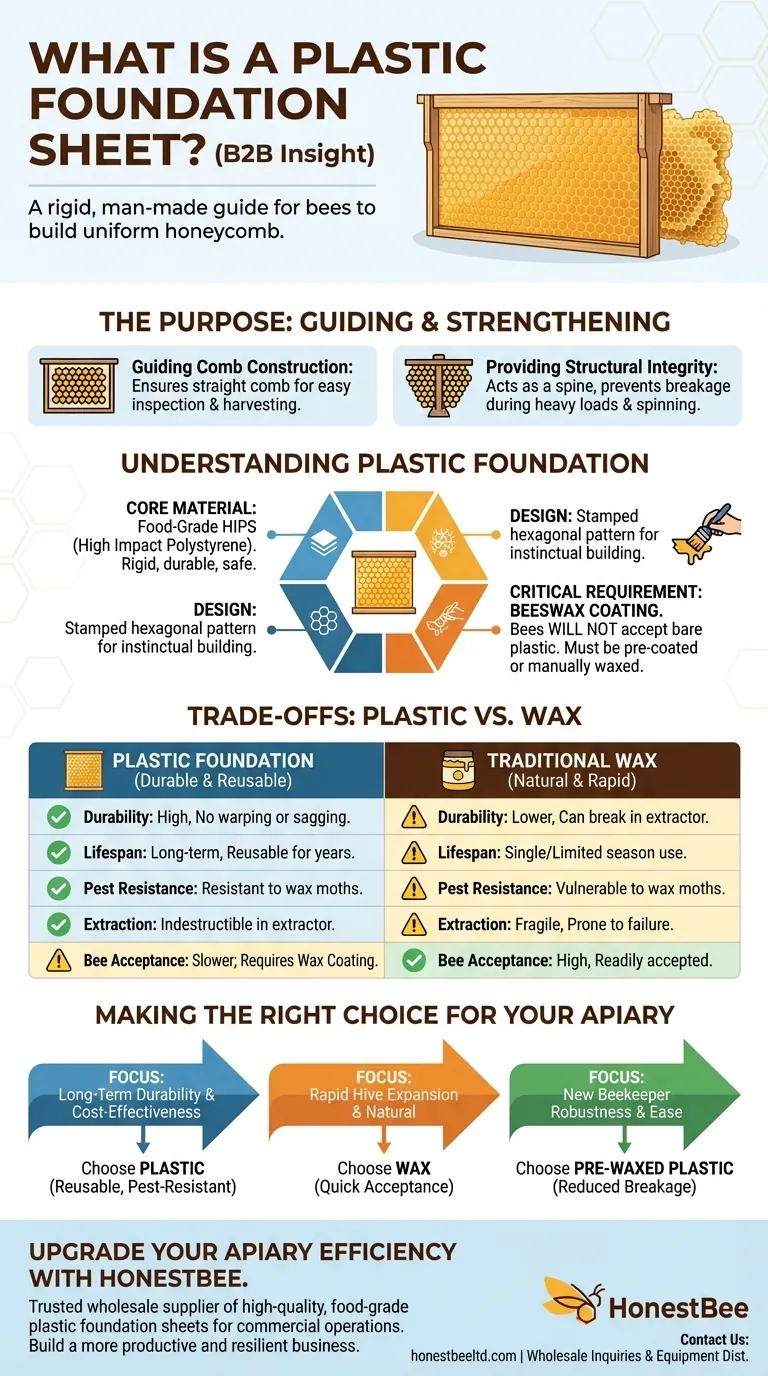

The Purpose of Foundation in the Hive

Foundation, whether wax or plastic, serves as a blueprint for the colony. It solves a critical problem for the beekeeper: managing the hive's internal structure.

Guiding Comb Construction

Without a guide, bees will build comb in natural, often irregular patterns. This can make it impossible to remove frames for inspection or honey harvesting without destroying the comb and potentially harming the queen.

Foundation encourages bees to build straight comb within the confines of the frame, ensuring each frame can be removed and inspected easily.

Providing Structural Integrity

The foundation sheet acts as a strong central spine for the honeycomb. This prevents the delicate comb from breaking, especially when it's heavy with honey or during the high-speed spinning of a honey extractor.

Understanding Plastic Foundation

Plastic foundation sheets are engineered for efficiency and longevity. Their design and material choice directly address some of the shortcomings of traditional beeswax.

Core Material and Design

Most plastic foundation is made from food-grade High Impact Polystyrene (HIPS). This material is chosen for its rigidity, durability, and safety for use in the hive.

The surface is stamped with the hexagonal cell pattern that bees instinctively use, providing them with a clear and efficient template to begin their work.

The Critical Beeswax Coating

Bees will not work with bare plastic. For a plastic foundation to be effective, it must be coated with a thin layer of beeswax.

Many manufacturers sell sheets that are already pre-coated. However, beekeepers can also buy uncoated sheets and apply melted beeswax themselves. A proper coating is the single most important factor for bee acceptance.

The Trade-offs: Plastic vs. Wax Foundation

Choosing between plastic and traditional beeswax foundation involves a clear set of compromises. Your decision depends entirely on your beekeeping goals and management style.

Key Advantages of Plastic

The primary benefit of plastic is its durability. It does not warp in high heat or sag under the weight of honey.

It is also largely indestructible during honey extraction, a common point of failure for fragile wax foundation. Furthermore, pests like wax moths cannot destroy the plastic base, and the sheets can be scraped clean and reused for many seasons.

Potential Downsides

The main challenge with plastic is bee acceptance. Some colonies are slower to build comb on plastic, even when it is well-coated with wax, compared to a pure beeswax foundation.

There is also the initial preparation. If the foundation is not pre-waxed, the beekeeper must take the extra step of melting and applying a wax coating before it can be used in the hive.

Making the Right Choice for Your Apiary

Your choice of foundation should align directly with your operational priorities.

- If your primary focus is long-term durability and cost-effectiveness: Plastic foundation is the superior choice because it can be reused for years, withstanding extraction and pests far better than wax.

- If your primary focus is rapid hive expansion and natural materials: Traditional beeswax foundation may be preferred, as bees often accept it and draw it out into comb more quickly.

- If you are a new beekeeper seeking robustness and ease of handling: Pre-waxed plastic foundation is an excellent starting point, as it significantly reduces the risk of breakages during your first inspections and honey harvests.

Ultimately, selecting the right foundation is a strategic decision that impacts the efficiency of your hive management.

Summary Table:

| Feature | Plastic Foundation | Traditional Wax Foundation |

|---|---|---|

| Durability | High (Won't warp or sag) | Lower (Can break in extractor) |

| Lifespan | Long-term, reusable | Single or limited season use |

| Pest Resistance | Resistant to wax moths | Vulnerable to wax moths |

| Bee Acceptance | Requires beeswax coating | High, readily accepted |

| Initial Prep | May require wax coating | Ready to use |

Upgrade your apiary's efficiency and durability with HONESTBEE.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide high-quality, food-grade plastic foundation sheets designed for superior performance and long-term value. Our wholesale-focused operations ensure you get the reliable equipment you need to build a more productive and resilient operation.

Contact HONESTBEE today to discuss your foundation needs and discover how our beekeeping supplies can benefit your business.

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- How do plastic bee frames and non-wax foundations contribute to the operational efficiency of a commercial apiary?

- What are the technical advantages of using wax-coated plastic sheets? Boost Royal Jelly Yields and Larval Acceptance

- What are the two ends of the spectrum in terms of frame and foundation choices? Plastic Efficiency vs. Natural Freedom

- What are the technical advantages of using beeswax-rich plastic foundation in commercial apiaries? Boost Your Honey Yield

- What are the advantages of using wood frames with plastic foundation in beekeeping? Boost Hive Durability & Efficiency

- What challenges in modern beehive management are addressed by using beeswax-coated plastic foundations? Boost Efficiency

- What are the pros and cons of using plastic foundation covered with beeswax? Boost Your Hive Acceptance and Durability

- What are the advantages of using pre-assembled plastic frames and foundations? Boost Commercial Beekeeping Efficiency