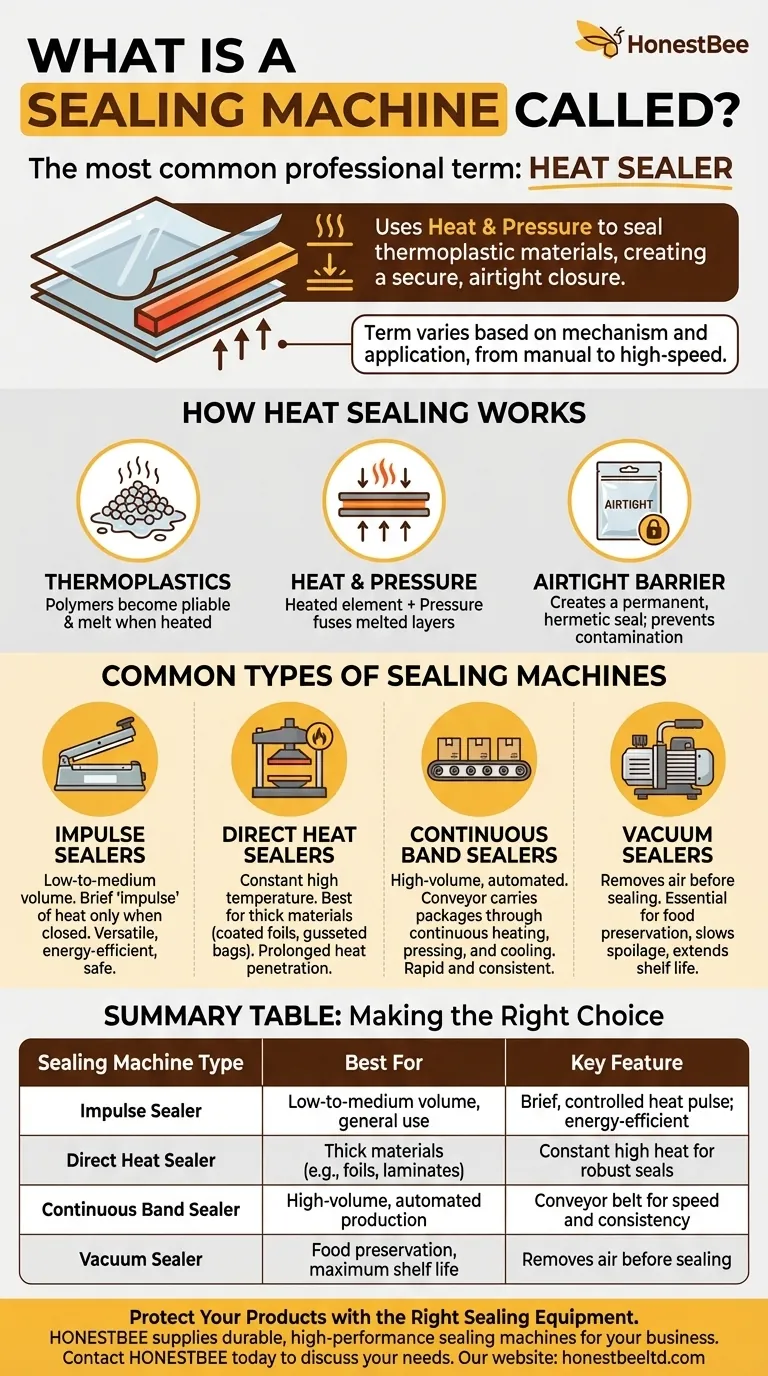

In professional and industrial contexts, a sealing machine is most commonly called a heat sealer. This device uses a combination of heat and pressure to seal thermoplastic materials, such as plastic bags or packaging films, creating a secure and often airtight closure.

While "heat sealer" is the correct general term, the specific name of the machine often changes based on its mechanism and intended application, ranging from simple manual devices to high-speed automated systems.

The Fundamental Principle: How Heat Sealing Works

At its core, heat sealing is a straightforward process that joins plastic materials together without adhesives. The effectiveness of the seal is critical for product protection, safety, and shelf life.

The Role of Thermoplastics

Heat sealers are designed to work with thermoplastics. These are polymers that become pliable and melt when heated and solidify upon cooling. This property is what allows two layers of film to be fused into a single, continuous piece.

Applying Heat and Pressure

The machine applies a heated element—such as a wire, bar, or wheel—to the packaging material. Simultaneously, pressure is applied to press the melted layers together, ensuring they fuse properly as they cool.

Creating an Airtight Barrier

The result is a permanent, hermetic seal. In industries like food and medical supplies, this airtight barrier is essential for preventing contamination, blocking moisture, and preserving the freshness and integrity of the contents.

Common Types of Sealing Machines

The term "heat sealer" is an umbrella category. The specific name often reflects how the machine operates and the scale of the operation it's designed for.

Impulse Sealers

These are the most common type for low-to-medium volume tasks. The heating element, typically a wire, is only energized for a brief moment (the impulse) when the sealing jaw is closed on the material. They are versatile, energy-efficient, and safe to operate.

Direct Heat Sealers

Also known as constant heat sealers, these machines maintain a high temperature in their sealing jaws at all times. They are better suited for thicker materials like coated foils or gusseted bags that require more prolonged heat penetration to achieve a strong seal.

Continuous Band Sealers

For high-volume, automated production lines, band sealers are the standard. Packages are placed on a motorized conveyor belt that carries them through a continuous process of heating, pressing, and cooling, resulting in rapid and consistent seals.

Vacuum Sealers

A specialized category of heat sealer, a vacuum sealer first removes air from the package before creating the final seal. This is crucial for food preservation, as removing oxygen significantly slows spoilage and extends shelf life.

Making the Right Choice for Your Goal

Selecting the correct machine depends entirely on your specific packaging needs, volume, and materials.

- If your primary focus is low-volume packaging for a small business or home use: An impulse sealer offers the best combination of affordability, versatility, and safety.

- If your primary focus is sealing thick, laminated, or foil-based bags: A direct heat sealer provides the consistent, high heat required for these robust materials.

- If your primary focus is high-volume, automated production: A continuous band sealer is the necessary tool for achieving industrial-level speed and consistency.

- If your primary focus is maximum food preservation and extending shelf life: A vacuum sealer is the essential device for removing air before sealing.

Understanding the correct terminology for your sealing needs allows you to select the precise tool to protect and present your product effectively.

Summary Table:

| Sealing Machine Type | Best For | Key Feature |

|---|---|---|

| Impulse Sealer | Low-to-medium volume, general use | Brief, controlled heat pulse; energy-efficient |

| Direct Heat Sealer | Thick materials (e.g., foils, laminates) | Constant high heat for robust seals |

| Continuous Band Sealer | High-volume, automated production | Conveyor belt for speed and consistency |

| Vacuum Sealer | Food preservation, maximum shelf life | Removes air before sealing |

Protect Your Products with the Right Sealing Equipment

Whether you're a commercial apiary sealing honey packs or a distributor supplying packaging solutions, choosing the correct heat sealer is critical for product integrity and efficiency. HONESTBEE supplies a full range of durable, high-performance beekeeping and packaging supplies, including sealing machines, through our wholesale-focused operations.

Contact HONESTBEE today to discuss your sealing needs. Our experts will help you select the ideal equipment to ensure your products are securely packaged and professionally presented.

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What are the benefits of using packaging machines? Boost Efficiency, Cut Costs & Elevate Your Brand

- What is a contour seal on a stick pack? Enhance Branding with Custom Shaped Packaging

- How do I choose a heat sealer? A Guide to Matching the Right Machine to Your Needs

- How is a heat sealer used in the production of honey sticks? Master the Art of Leak-Proof Sealing

- How does a sealing machine work? Ensure Product Integrity with a Perfect Hermetic Seal