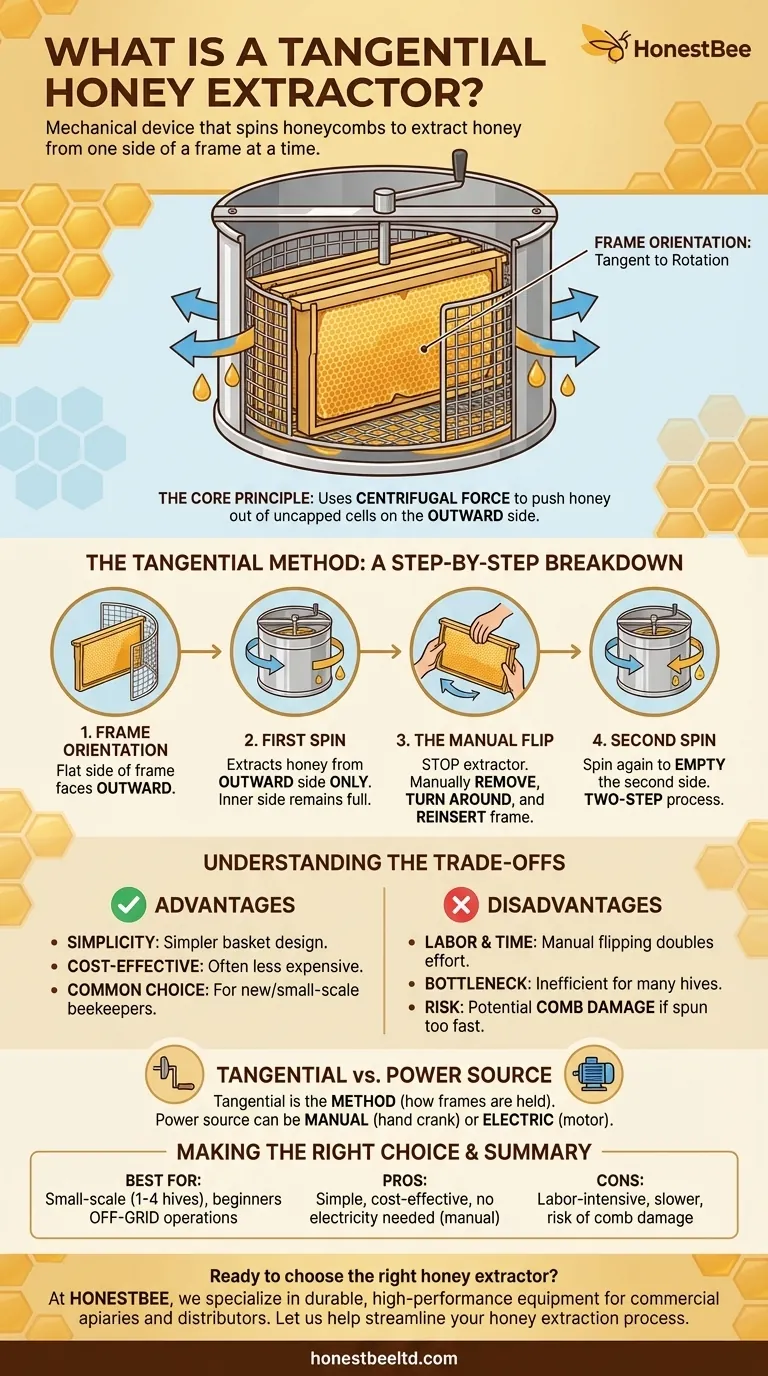

At its core, a tangential honey extractor is a mechanical device that spins honeycombs to extract honey from one side of a frame at a time. The frames are placed inside a drum, resting against a mesh screen with one face of the honeycomb pointing outwards. When the extractor spins, centrifugal force flings the honey out of the uncapped cells on that outward-facing side only, requiring the beekeeper to stop, flip the frames, and repeat the process for the other side.

While all honey extractors use centrifugal force, a tangential extractor is defined by its frame orientation. It extracts from one side of the comb at a time, a trade-off that makes it a simple and effective design, but one that is more labor-intensive than other types.

The Fundamental Principle: How All Extractors Work

Before focusing on the tangential design, it's crucial to understand the universal principle behind all honey extraction.

Harnessing Centrifugal Force

An extractor is a drum containing a rotating basket, or cage. Uncapped frames of honey are placed in the cage, which is then spun at high speed. This rotation creates a strong centrifugal force that pushes the liquid honey out of the wax cells.

Preserving the Comb

The primary benefit of an extractor is that it removes honey without destroying the wax comb. The honey runs down the inner walls of the drum and pools at the bottom. This allows the beekeeper to return the empty, intact combs to the hive, saving the bees the enormous energy and time required to build new wax.

The Collection Process

A tap or "honey gate" at the bottom of the drum allows the collected honey to be drained. It's important to drain the honey periodically so the level does not rise high enough to interfere with the rotating frames.

The Tangential Method: A Step-by-Step Breakdown

The defining characteristic of a tangential extractor is the specific orientation of the frames and the manual process it requires.

Frame Orientation is Key

In a tangential design, the frames are positioned so they are tangent to the circle of rotation. In simpler terms, one flat side of the frame faces directly outward, resting against the basket's mesh wall.

The First Spin

When you begin spinning the basket, honey is extracted only from the cells on the outward-facing side of the comb. The inner side remains full, shielded from the primary force.

The Manual Flip

After the first side is empty, you must stop the extractor. Each frame is then manually removed, turned around, and placed back in the basket so the previously un-extracted side now faces outward.

The Second Spin

You then spin the extractor again to empty the second side of the comb. This two-step process is the operational signature of a tangential extractor.

Understanding the Trade-offs

The tangential design presents a clear set of advantages and disadvantages that make it ideal for some situations and inefficient for others.

Advantage: Simplicity and Cost

Tangential extractors often have a simpler basket design than other types. This mechanical simplicity can make them less expensive and a common choice for new or small-scale beekeepers.

Disadvantage: Labor and Time

The need to stop, flip every frame, and restart the process doubles the amount of hands-on labor and time required per batch. This becomes a significant bottleneck when processing a large number of frames.

Risk: Potential for Comb Damage

Because force is applied to only one side of a heavy, full frame, spinning too fast initially can cause the comb to "blow out" or collapse from the weight of the honey on the un-extracted side. Experienced users often perform a partial extraction on the first side, flip the frames, perform a full extraction on the second side, and then flip back to finish the first.

Tangential vs. Electric/Manual: A Point of Clarification

It is easy to confuse the extraction method (tangential) with the power source (manual or electric). These are separate features.

Frame Orientation vs. Power Source

A tangential extractor refers only to how the frames are held. This design can be powered either by a hand crank or an electric motor.

The Manual Option

A manual tangential extractor uses a hand crank to spin the basket. This is a reliable, cost-effective option for beekeepers with only a few hives and no access to electricity at their extraction site.

The Electric Option

An electric tangential extractor uses a motor to automate the spinning. This reduces physical effort and allows for more consistent speed control, but it does not eliminate the need to manually flip the frames.

Making the Right Choice for Your Operation

Deciding if a tangential extractor is right for you depends entirely on the scale and goals of your beekeeping.

- If your primary focus is starting out or small-scale production (1-4 hives): A manual tangential extractor is often the most cost-effective and straightforward choice.

- If your primary focus is efficiency and processing many hives: The manual flipping required by a tangential extractor will become a significant bottleneck, and you should investigate other designs.

- If your primary focus is working off-grid: A manual tangential extractor provides a robust solution that is not dependent on electricity.

Understanding this core design principle is the first step toward choosing the right equipment for your beekeeping goals.

Summary Table:

| Feature | Tangential Extractor |

|---|---|

| Operation | Extracts honey from one side of the frame at a time; requires manual flipping |

| Best For | Small-scale beekeepers (1-4 hives), beginners, or off-grid operations |

| Pros | Simple design, cost-effective, no electricity required (manual option) |

| Cons | Labor-intensive, slower for large batches, risk of comb damage if spun too fast |

Ready to choose the right honey extractor for your apiary?

At HONESTBEE, we specialize in supplying durable, high-performance beekeeping equipment to commercial apiaries and distributors. Whether you're a small-scale beekeeper starting out or a large operation scaling up, we provide wholesale-focused solutions tailored to your needs.

Let us help you streamline your honey extraction process. Contact our experts today to discuss the best equipment for your goals!

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

People Also Ask

- What are the advantages of using a professional centrifugal honey extractor? Boost Yield and Purity in Your Apiary

- How do I choose a honey extractor? Match Your Apiary Size for Maximum Efficiency

- How much honey does 1 bee hive make? Unlock the Secrets to Maximizing Your Honey Yield

- Why is a specialized honey centrifuge necessary? Boost Yield and Protect Your Bees

- How do you extract honey from a beehive? A Guide to Efficient & Bee-Friendly Methods

- What are the processing advantages of using centrifugal honey extractors? Maximize Yield and Preserve Hive Integrity

- Why is the use of centrifugal honey extractors essential? Maximize Hive Yield with Advanced Extraction Technology

- What is the primary function of centrifugal honey extraction equipment? Boost Your Yield with Comb Preservation