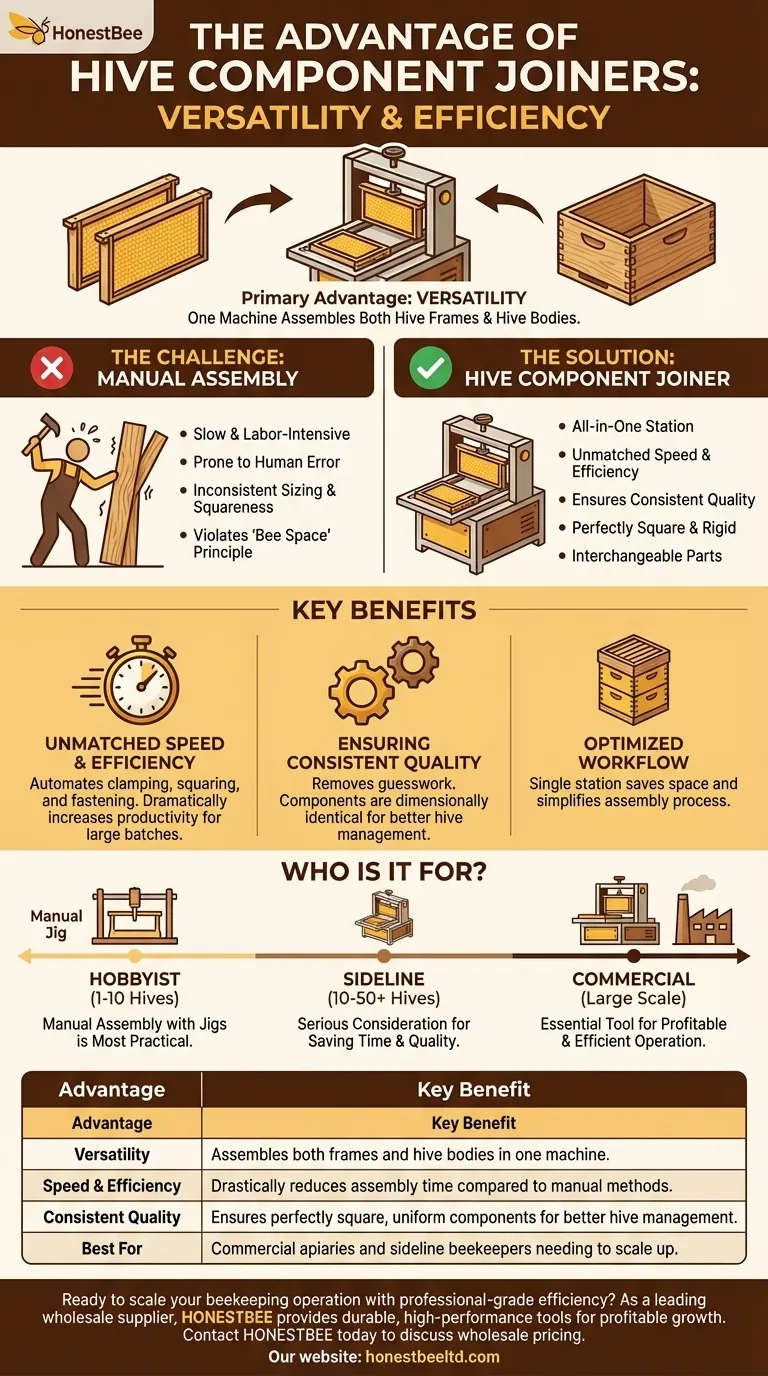

In short, the primary advantage of a hive component joiner is its versatility. This single machine is engineered to assemble both hive frames and hive bodies (boxes), providing a unified, all-in-one solution that streamlines the entire hive construction process for a beekeeper.

Beekeepers often face the time-consuming and repetitive task of assembling wooden components. A hive component joiner addresses this by combining multiple assembly jobs into one efficient station, delivering a level of speed and precision that is difficult to replicate with manual tools.

The Challenge of Assembling Hive Components

To appreciate the value of a joiner, it is first necessary to understand the challenges of traditional hive assembly. This process is fundamental to beekeeping but is often a significant bottleneck.

The Problem with Manual Assembly

Manually building hive bodies and frames typically involves a hammer, nails, wood glue, and a square. While effective, this method is slow and prone to human error.

Achieving perfectly square boxes and uniform frames by hand, piece by piece, requires significant time and skill. Inconsistencies can easily arise, especially when assembling components in large batches.

Why Precision Matters in Beekeeping

The internal dimensions of a beehive are not arbitrary. Beekeepers must respect the principle of "bee space"—a specific gap that bees will not build comb in or seal with propolis.

Improperly assembled frames or out-of-square boxes can violate this bee space. This leads to issues like burr comb, difficulty removing frames for inspection, and a less manageable hive.

How a Component Joiner Solves the Problem

A hive component joiner is a specialized piece of workshop equipment designed specifically to overcome the challenges of speed and consistency in hive assembly.

An All-in-One Solution

The most significant benefit, as noted in the references, is that these machines are designed to handle both frames and boxes.

Instead of needing separate jigs for different components, a beekeeper can use a single, optimized station for their primary assembly needs, saving space and simplifying their workflow.

Unmatched Speed and Efficiency

For beekeepers managing more than a few hives, time is a critical resource. A component joiner automates the clamping, squaring, and often the fastening of components.

This allows a single person to assemble frames or boxes in a fraction of the time it would take manually, dramatically increasing productivity during the busy season or when expanding an apiary.

Ensuring Consistent Quality

A joiner removes the guesswork from assembly. It holds components in a perfectly square and rigid position while they are fastened.

The result is a batch of hive bodies and frames that are dimensionally identical. This uniformity makes hive management easier, as parts are perfectly interchangeable and frames slide out smoothly during inspections.

Understanding the Trade-offs

While powerful, a hive component joiner is not the right tool for every beekeeper. Objectively weighing the downsides is crucial before making an investment.

The Initial Cost

These machines represent a significant financial investment. The cost can be difficult to justify for a hobbyist with only a handful of hives, as the time saved may not outweigh the expense.

Best Suited for Scale

The true value of a component joiner emerges at scale. Its efficiency benefits are most apparent when a beekeeper needs to assemble dozens of hive bodies or hundreds of frames at once.

For small-scale beekeepers, simpler and cheaper frame assembly jigs often provide a more practical balance of cost and benefit.

Workshop Space and Maintenance

A component joiner is another piece of equipment that requires storage space in a workshop. Like any machine, it also requires periodic maintenance to ensure it continues to operate accurately and safely.

Making the Right Choice for Your Operation

Deciding whether to invest in a hive component joiner depends entirely on the scale and goals of your beekeeping operation.

- If your primary focus is hobby beekeeping (1-10 hives): Manual assembly using simple, inexpensive jigs is almost always the most practical and cost-effective approach.

- If your primary focus is growing a sideline business (10-50+ hives): A component joiner becomes a serious consideration for saving valuable time and ensuring high-quality, interchangeable equipment.

- If your primary focus is commercial beekeeping: The efficiency, speed, and consistency offered by a component joiner make it an essential tool for profitable operation.

Ultimately, a hive component joiner is a specialized tool that trades a high initial cost for unparalleled efficiency and quality at scale.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Versatility | Assembles both frames and hive bodies in one machine. |

| Speed & Efficiency | Drastically reduces assembly time compared to manual methods. |

| Consistent Quality | Ensures perfectly square, uniform components for better hive management. |

| Best For | Commercial apiaries and sideline beekeepers needing to scale up. |

Ready to scale your beekeeping operation with professional-grade efficiency?

As a leading wholesale supplier, HONESTBEE provides commercial apiaries and beekeeping equipment distributors with the durable, high-performance tools needed for profitable growth. A hive component joiner is just one example of the equipment that can transform your productivity.

Contact HONESTBEE today to discuss wholesale pricing and how our supplies can support your commercial success.

Visual Guide

Related Products

- Multi-Function Plier-Style Frame Grip Hive Tool

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional Stainless Steel Pry-Bar Hive Tool

People Also Ask

- Why use Langstroth frame measuring tools with wire grids? Achieve Scientific Accuracy in Brood Assessment

- What is the purpose of specialized colony splitting tools? Grow Your Apiary with Strategic Colony Multiplication

- How do professional protective and collection equipment contribute to pollination? Scale Your Apiary Efficiency

- What are the normal functions of a hive tool? The Essential Multi-Tool for Every Beekeeper

- What temperature is too cold to open a beehive? Protect Your Hive from Fatal Cold Shock