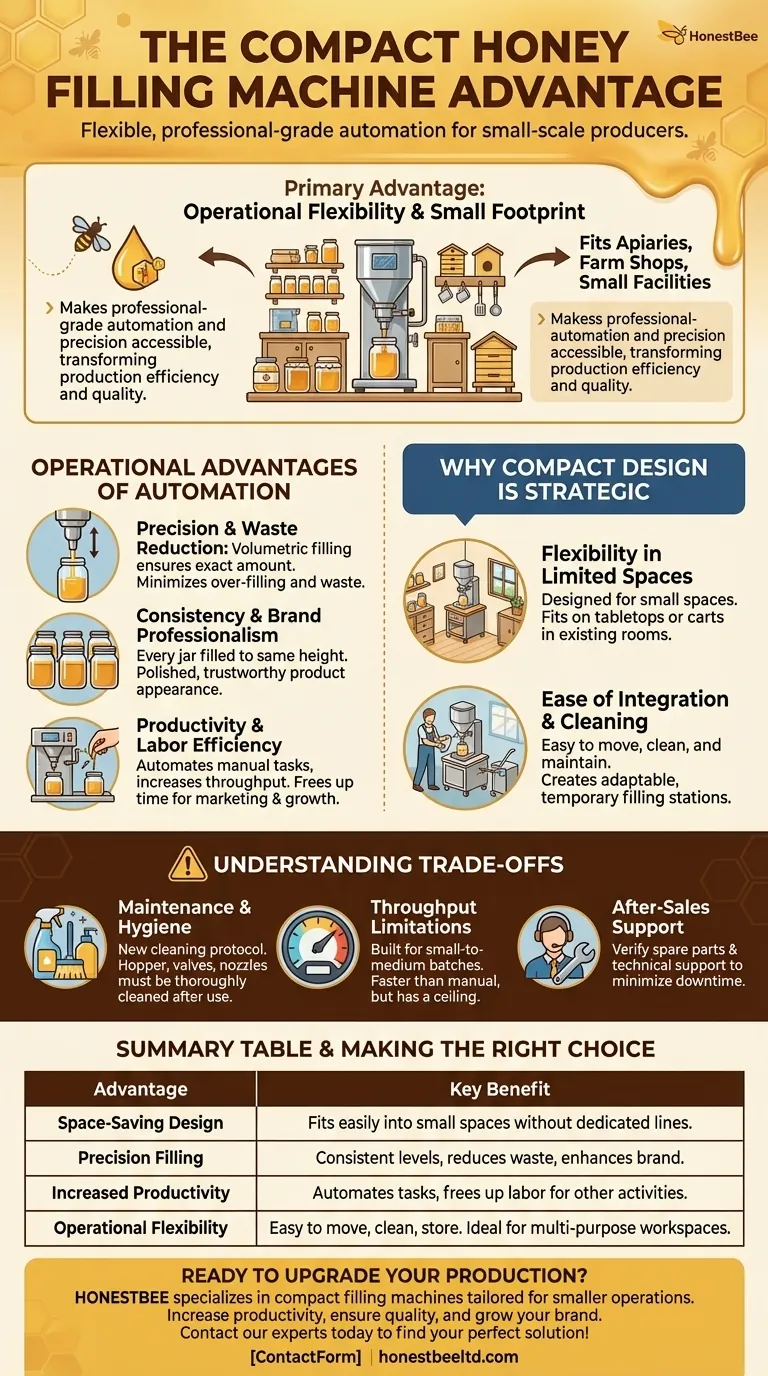

The primary advantage of a compact honey filling machine is its operational flexibility, especially for small-scale producers. Its small footprint allows it to be integrated into environments where space is a premium, such as apiaries, farm shops, or small food manufacturing facilities, without requiring a dedicated, large-scale production line.

While the compact size is the most visible feature, its true value lies in making professional-grade automation and precision accessible to smaller businesses, fundamentally transforming their production efficiency and product quality.

The Operational Advantages of Automation

A filling machine, regardless of its size, introduces a new level of control and efficiency to your process. The benefits go far beyond simply packaging honey faster.

Precision and Waste Reduction

Modern honey fillers operate on a volumetric filling principle. You enter a precise volume, and the machine dispenses that exact amount every single time.

This is achieved as honey flows from a hopper through a nozzle, with sensors and valves controlling the flow to ensure accuracy. This mechanical precision virtually eliminates over-filling and product waste.

Consistency and Brand Professionalism

Inconsistent fill levels in jars can make a product look unprofessional and untrustworthy. Automation ensures every jar is filled to the exact same height.

This consistency gives your product a polished, high-quality appearance on the shelf, which is critical for building a strong brand identity.

Productivity and Labor Efficiency

Manually filling jars is a time-consuming and labor-intensive task. Automating this process dramatically increases throughput.

This frees up valuable time and labor, which can be reallocated to other critical business activities like marketing, beekeeping, or product development.

Why a Compact Design Is a Strategic Advantage

For small producers, the "compact" feature is not just a convenience—it's what makes the investment viable in the first place.

Flexibility in Limited Spaces

Large, industrial filling lines are impractical and unaffordable for most small businesses. A compact machine is designed specifically for their reality.

It can be placed on a sturdy tabletop or a small cart, fitting easily into an existing multi-purpose room, a small commercial kitchen, or even a converted garage.

Ease of Integration and Cleaning

A smaller machine is inherently easier to move, clean, and maintain. This is a significant advantage in operations where the same space may be used for different tasks throughout the day.

Its mobility allows you to create a temporary "filling station" and then store the machine away, keeping your workspace adaptable.

Understanding the Trade-offs

While beneficial, investing in any machine comes with new responsibilities and limitations that must be considered.

Maintenance and Hygiene Demands

A machine introduces a new cleaning and maintenance protocol. To ensure food safety and prevent spoilage, the hopper, valves, and nozzles must be thoroughly cleaned after each use.

This is a non-negotiable operational task that requires time and diligence.

Throughput Limitations

A compact machine is built for small-to-medium batch production, not high-volume industrial output. It will be significantly faster than manual filling but has a ceiling on its hourly capacity.

Be realistic about your production goals and ensure the machine’s specified throughput matches your expected growth.

The Importance of After-Sales Support

Machine downtime can halt your entire production. Before purchasing, verify the availability of spare parts and technical support from the manufacturer.

Reliable support minimizes downtime and protects your investment, ensuring long-term operational efficiency.

Making the Right Choice for Your Goal

A compact filling machine is a strategic tool. Your primary goal should guide your decision.

- If your primary focus is scaling up from manual filling: The machine will deliver immediate returns in time saved, reduced waste, and product consistency.

- If your primary focus is maintaining brand quality: Automation is the most reliable way to ensure a professional and consistent product presentation every time.

- If your primary focus is operating in a tight space: The compact design is the enabling feature that makes professional automation possible for your business.

Ultimately, a compact honey filling machine is not just about saving space; it's about gaining precise control over your production process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Space-Saving Design | Fits easily into apiaries, farm shops, and small kitchens without a dedicated production line. |

| Precision Filling | Volumetric technology ensures consistent fill levels, reduces waste, and enhances brand professionalism. |

| Increased Productivity | Automates manual tasks, freeing up labor for marketing, beekeeping, and other business activities. |

| Operational Flexibility | Easy to move, clean, and store, making it ideal for multi-purpose workspaces. |

Ready to upgrade your honey production with a machine designed for your scale?

HONESTBEE specializes in supplying high-quality, commercial-grade beekeeping supplies and equipment to apiaries and distributors. Our compact honey filling machines are engineered to deliver the precision and efficiency of large-scale automation, perfectly tailored for smaller operations.

Let us help you increase your productivity, ensure consistent product quality, and grow your brand. Contact our experts today to find the perfect filling solution for your business!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do automated honey filling machines ensure product quality? Enhance Standardization for Commercial Distribution

- What is the role of the emergency stop button in a honey stick machine? A Critical Safety Mechanism Explained

- In what ways do automatic honey-filling machines facilitate professional production? Scale Your Apiary Efficiently

- How does honey filling and packaging equipment contribute to the commercialization of bee products? Scaling Your Success

- In what way do high-efficiency honey-filling machines contribute to beekeeping sustainability? Boost Your Profit Margins

- What are the different types of filling mechanisms used in honey filling machines? Choose the Right Tech for Your Honey

- How do industrial honey filtration and filling machines improve honey's market value? Transform Your Raw Harvest

- Why is filling accuracy important in a honey filling machine? Maximize Profit and Build Brand Trust