Ultimately, piston filling machines excel where other technologies fail: accurately dispensing viscous, semi-viscous, or chunky products. While many machines can fill a bottle with a free-flowing liquid, a piston filler uses a precise, powerful mechanical action to handle challenging products like thick pastes, creams, and sauces with particulates, ensuring each container is filled with an exact volume.

The decision to use a piston filler is not just about a product's thickness. It is a strategic choice for operations that prioritize volumetric accuracy, need to handle particulates without damage, and work with products that will not flow easily on their own.

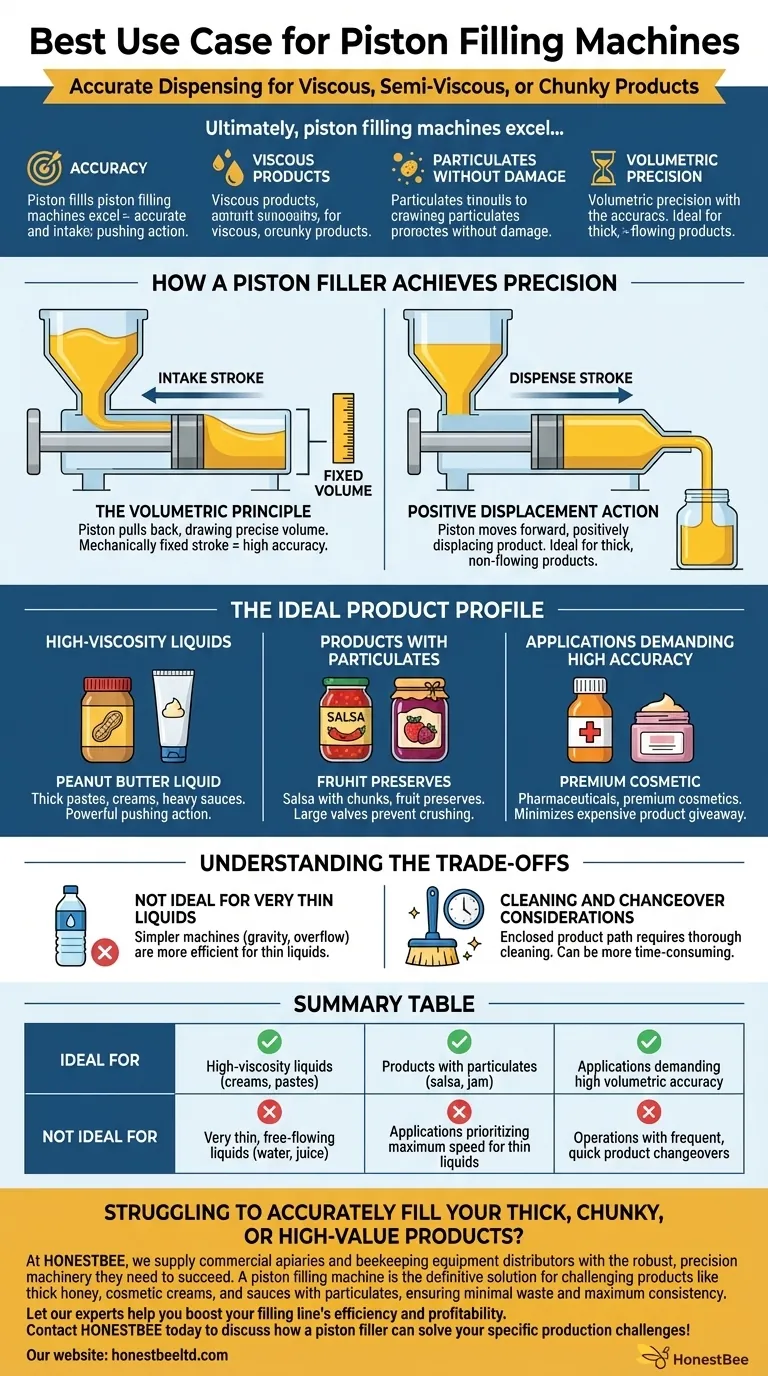

How a Piston Filler Achieves Precision

A piston filler is a type of volumetric filling machine. Its effectiveness comes from its simple and highly controllable mechanical design.

The Volumetric Principle

The core of the machine is a product cylinder. During the intake stroke, a piston pulls back, drawing a precise volume of product from a hopper into this cylinder.

The volume is determined by the cylinder's diameter and the length of the piston's stroke, both of which are mechanically fixed and repeatable, leading to very high fill accuracy.

Positive Displacement Action

On the dispense stroke, the piston moves forward, positively displacing the product and forcing it out of the cylinder and through a nozzle into your container.

This powerful pushing action is what makes piston fillers ideal for thick products that would not flow consistently under gravity alone. It ensures a smooth, controlled dispense for everything from thick honey to heavy lotions.

The Ideal Product Profile for a Piston Filler

Certain product characteristics strongly indicate that a piston filler is the superior choice for your production line.

High-Viscosity Liquids

This is the classic use case. A piston filler provides the force needed to move thick products that resist flowing.

Think of products like peanut butter, cosmetic creams, heavy sauces, gels, and pastes. A piston filler handles these with ease and accuracy.

Products with Particulates

This is a critical and often overlooked advantage. Piston fillers can be configured with large valves and nozzles that allow products with solids to pass through without being crushed or clogging the machine.

This makes them the go-to solution for products like salsa with vegetable chunks, fruit preserves, pasta sauces, and even potato salad.

Applications Demanding High Accuracy

Because the fill volume is mechanically set, piston fillers are exceptionally accurate. This minimizes expensive product giveaway and ensures consistency from one container to the next.

For high-value products like pharmaceuticals or premium cosmetics, this level of accuracy is not just a benefit—it's a financial necessity.

Understanding the Trade-offs

No single technology is perfect for every application. To make an informed decision, you must also understand a piston filler's limitations.

Not Ideal for Very Thin Liquids

While a piston filler can dispense water-thin liquids, it is often not the most efficient choice. The seals required to prevent drips with low-viscosity products can be complex.

For products like water, juice, or solvents, a simpler and often faster machine like a gravity filler or overflow filler is typically more cost-effective.

Cleaning and Changeover Considerations

The enclosed product path—from the hopper through the cylinder, piston, and nozzle—requires thorough cleaning between product runs to ensure sanitation and prevent cross-contamination.

This cleaning process can be more time-consuming than for simpler fillers with more open designs. Quick-disconnect fittings and clean-in-place (CIP) systems can mitigate this, but it remains a key operational factor.

Making the Right Choice for Your Product

To select the correct technology, match the machine's strengths to your primary operational goal.

- If your product is thick, pasty, or contains chunks like salsa or jam: A piston filler is the most reliable and accurate choice for handling these challenging characteristics.

- If your product is a free-flowing, low-viscosity liquid like juice or window cleaner: You should evaluate gravity or overflow fillers, which may offer higher speeds and simpler operation for your application.

- If your absolute priority is minimizing waste for a high-value liquid: A piston filler's superior volumetric accuracy offers a significant financial advantage that often outweighs other considerations.

Choosing the right filling technology is a foundational decision that directly impacts your product consistency, efficiency, and profitability.

Summary Table:

| Ideal For | Not Ideal For |

|---|---|

| High-viscosity liquids (creams, pastes) | Very thin, free-flowing liquids (water, juice) |

| Products with particulates (salsa, jam) | Applications prioritizing maximum speed for thin liquids |

| Applications demanding high volumetric accuracy | Operations with frequent, quick product changeovers |

Struggling to accurately fill your thick, chunky, or high-value products?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the robust, precision machinery they need to succeed. A piston filling machine is the definitive solution for challenging products like thick honey, cosmetic creams, and sauces with particulates, ensuring minimal waste and maximum consistency.

Let our experts help you boost your filling line's efficiency and profitability.

Contact HONESTBEE today to discuss how a piston filler can solve your specific production challenges!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

People Also Ask

- What is the difference between a single-lane and a multi-lane honey stick machine? Scale Your Honey Packaging Today

- What are the features of an automatic honey stick machine? Maximize Your High-Volume Honey Production

- How do industrial honey-filling machines enhance the commercial distribution of bee products? Maximize Your Market Reach

- What are the differences between semi-automatic and fully automatic honey filling machines? A Guide to Choosing the Right Machine for Your Apiary

- What is the general working principle of honey filling machines? Master Precision & Automation in Your Apiary

- How do automated honey filling machines ensure product quality? Enhance Standardization for Commercial Distribution

- How does the implementation of high-precision honey filling and sealing machinery affect honey product value?

- What is a Multi Lane Honey Sachet Packing Machine and when is it used? Maximize Your High-Volume Honey Production