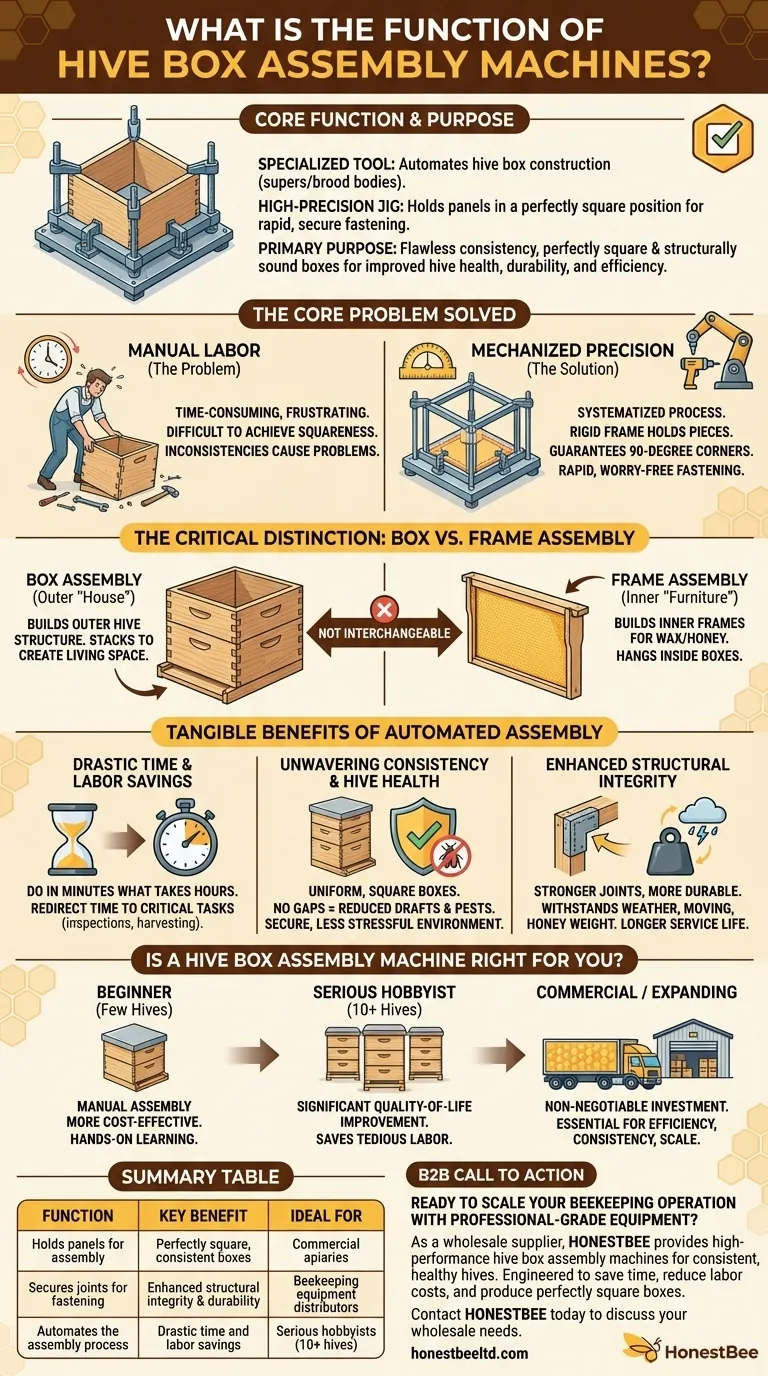

At its core, a hive box assembly machine is a specialized tool designed to automate the construction of the wooden boxes (known as supers or brood bodies) that form the main structure of a beehive. It acts as a high-precision jig, holding the four wooden panels of a hive box in a perfectly square position, allowing you to quickly and securely fasten them together with nails or staples.

The true function of a hive box assembly machine extends beyond mere speed. Its primary purpose is to deliver flawless consistency, ensuring every hive box is perfectly square and structurally sound, which directly impacts hive health, durability, and the beekeeper's long-term efficiency.

The Core Problem Solved: From Manual Labor to Mechanized Precision

Manually assembling hive boxes is a time-consuming and often frustrating task. Achieving a perfectly square and gap-free box by hand is difficult, and inconsistencies can cause significant problems down the line. Assembly machines solve this by systematizing the entire process.

What the Machine Actually Does

A hive box assembly machine provides a rigid frame that holds the four pre-cut, interlocking pieces of a hive box. By clamping the pieces into place, it guarantees a 90-degree corner on every joint. This allows the beekeeper to drive fasteners in rapidly without worrying about the box shifting or becoming skewed.

The Critical Distinction: Box vs. Frame Assembly

It is crucial to distinguish between a box assembly machine and a frame assembly machine. While both streamline beehive construction, they serve two entirely different functions.

- Box Assembly: Builds the outer "house" of the hive—the large wooden boxes that stack to create the colony's living space.

- Frame Assembly: Builds the inner "furniture"—the wooden frames that hold the beeswax foundation and hang inside the boxes.

An operation may use one, the other, or both, but they are not interchangeable pieces of equipment.

The Tangible Benefits of Automated Assembly

Investing in an assembly machine provides clear, measurable advantages that compound over time, especially for beekeepers managing more than a few hives.

Drastic Time and Labor Savings

This is the most immediate benefit. What might take 15-20 minutes to assemble carefully by hand can be done in a fraction of that time with a machine. This allows beekeepers to redirect their valuable time toward more critical tasks like colony inspections, pest management, and honey harvesting.

Unwavering Consistency and Hive Health

A machine produces uniform, square boxes every time. This consistency is not just for aesthetics; it is vital for improving hive health.

Perfectly aligned boxes stack without gaps, reducing drafts and preventing pests like wax moths or small hive beetles from finding easy entry points. This creates a more secure, less stressful environment for the bees.

Enhanced Structural Integrity

By holding the joints tightly together during fastening, the machine ensures a stronger, more durable final product. These well-built boxes can better withstand the rigors of weather, frequent moving, and the weight of honey, resulting in a longer service life for your equipment.

Understanding the Trade-offs

While highly effective, a hive box assembly machine is not the right choice for every beekeeper. Objectively considering the downsides is essential.

The Initial Cost of Investment

These machines represent a significant financial outlay compared to a hammer and a carpenter's square. For beekeepers with only a handful of hives, the cost is difficult to justify when weighed against the benefits.

The Question of Scale

The return on investment for an assembly machine is directly tied to the scale of your operation. It becomes invaluable when assembling dozens or hundreds of boxes a year. For a hobbyist assembling five boxes, the setup time might negate any speed advantage.

Is a Hive Box Assembly Machine Right for You?

Choosing to invest in this equipment depends entirely on your specific goals, the scale of your operation, and how you value your time.

- If you are a commercial beekeeper or expanding rapidly: The machine is a non-negotiable investment for achieving efficiency, consistency, and durability at scale.

- If you are a serious hobbyist managing 10+ hives: The machine becomes a significant quality-of-life improvement, saving you hours of tedious labor and ensuring your equipment is top-notch.

- If you are a beginner with just a few hives: Manual assembly is more cost-effective and provides a valuable hands-on understanding of hive construction.

Ultimately, the right choice depends on balancing the immediate cost against the long-term value of precision and time in your beekeeping operation.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Holds panels for assembly | Perfectly square, consistent boxes | Commercial apiaries |

| Secures joints for fastening | Enhanced structural integrity & durability | Beekeeping equipment distributors |

| Automates the assembly process | Drastic time and labor savings | Serious hobbyists (10+ hives) |

Ready to scale your beekeeping operation with professional-grade equipment?

As a wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, high-performance hive box assembly machines you need to build consistent, healthy hives efficiently. Our equipment is engineered to save you time, reduce labor costs, and produce perfectly square boxes that support colony health.

Contact HONESTBEE today to discuss your wholesale needs and discover how our solutions can strengthen your business.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Metal Bee Hive Stand Bee Box Stand for Beekeeping

People Also Ask

- What are the benefits of using automated hive-making machines? Boost Precision & Profit in Beekeeping Manufacturing

- How can hive manufacturing machinery address Apis dorsata decline? Tech Solutions for Nesting Site Loss

- Why is it necessary to mechanically increase the internal surface texture during beehive manufacturing? Boost Bee Health

- How do adjustable plugs and foam inserts function within cylindrical beekeeping hives? Optimize Hive Volume

- Why is commercial beehive design critical for CCD & pesticide monitoring? Discover how hives serve as diagnostic tools.

- How do automated hive-making machines assist the beekeeping industry? Boost Resilience in Changing Environments

- What role does standardized wooden beehive manufacturing machinery play? Scale Your Apiary with Industrial Precision

- What role do hive-making and assembly machines play in the economic development of start-up beekeeping operations? Scale