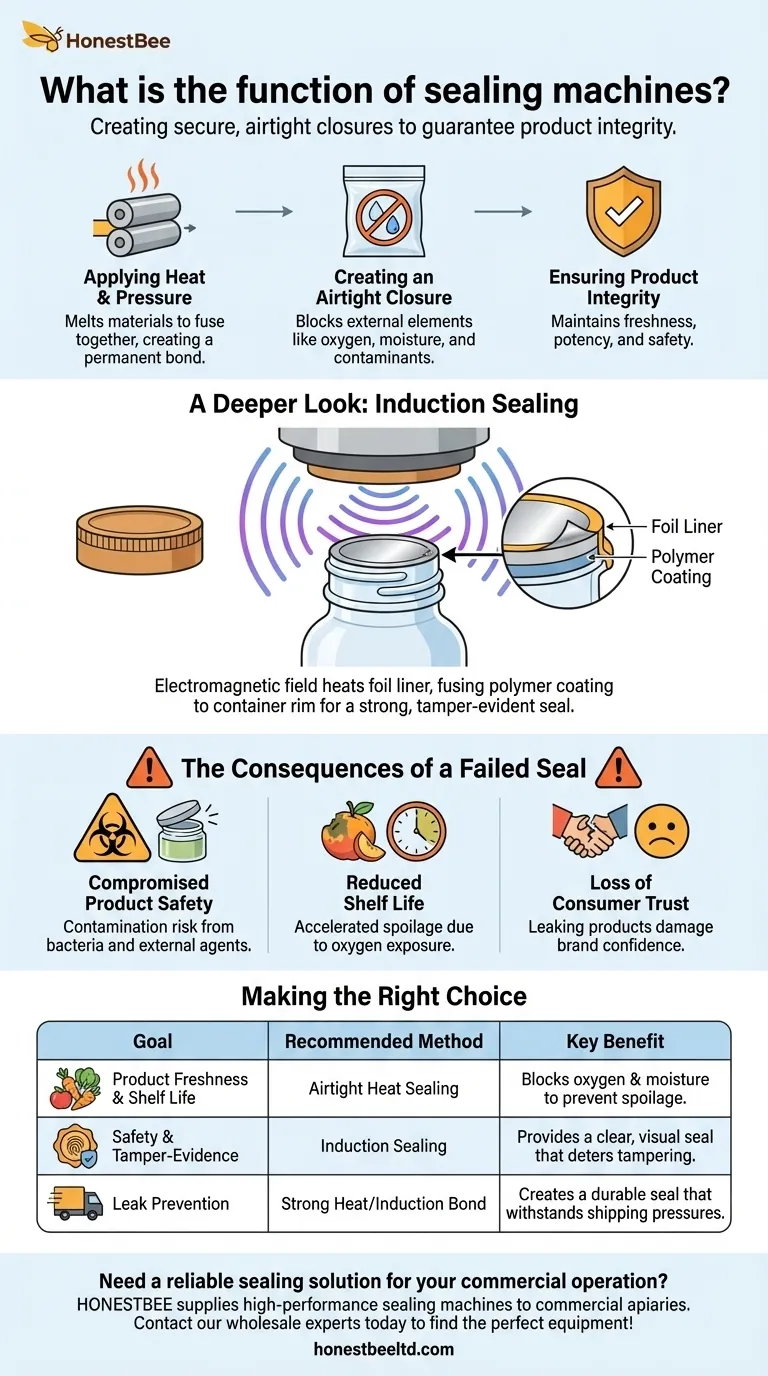

At its core, a sealing machine's function is to create a secure, airtight closure on a package or container. By applying a combination of heat and pressure, these machines bond materials together, forming a protective barrier that isolates the contents from the external environment. This is essential for preserving product quality and ensuring consumer safety.

The true purpose of a sealing machine extends beyond simple closure; it is a critical tool for guaranteeing product integrity. Its function is to prevent contamination, eliminate leaks, extend shelf life, and provide clear evidence of tampering.

The Core Principle: How Sealing Creates a Barrier

A reliable seal is the final, crucial step in the packaging process. It acts as a gatekeeper, protecting the product from the moment it leaves the production line until it reaches the end user.

Applying Heat and Pressure

The most fundamental method involves applying controlled heat and pressure to thermoplastic materials. This process melts the sealing surfaces just enough to fuse them together, creating a permanent, unified bond as they cool.

Creating an Airtight Closure

This bond results in an airtight seal. Its primary job is to block external elements like oxygen, moisture, and contaminants from entering the package, which are often the primary causes of spoilage and degradation.

Ensuring Product Integrity

By creating this protective barrier, the sealing process is directly responsible for maintaining the freshness, potency, and safety of the product inside. This is non-negotiable in industries like food, beverage, and pharmaceuticals.

A Deeper Look: Induction Sealing

While direct heat is common, a more advanced method called induction sealing is used for containers with caps, such as bottles and jars. This technique offers a highly secure and tamper-evident closure.

The Role of Electromagnetism

An induction sealing machine uses a non-contact process. A sealing head generates an electromagnetic field that passes through the plastic cap without heating it.

The Foil Liner and Polymer Coating

Inside the cap is a multi-layer liner, which typically includes a layer of aluminum foil. This foil liner has a polymer coating on the side that will face the container's opening.

The Fusing Process

The electromagnetic field excites the particles in the foil, causing it to heat up rapidly. This heat melts the polymer coating, which then fuses onto the rim of the container. As it cools, it creates a strong, airtight, and tamper-evident seal.

The Consequences of a Failed Seal

Understanding the function of a sealing machine also means appreciating the risks of a poor or failed seal. The consequences are significant and can impact safety, cost, and brand reputation.

Compromised Product Safety

The most severe risk is product contamination. A broken seal allows bacteria, moisture, and other external agents to enter, potentially rendering the product unsafe for consumption.

Reduced Shelf Life

For many products, exposure to oxygen is the primary driver of spoilage. A faulty seal accelerates this process, drastically reducing the product's shelf life and leading to waste.

Loss of Consumer Trust

A leaking container or a product that is not fresh upon opening immediately damages consumer confidence. A secure seal is a direct reflection of a brand's commitment to quality and safety.

Making the Right Choice for Your Goal

The specific sealing function you prioritize depends entirely on your product and its requirements.

- If your primary focus is product freshness and shelf life: The key is achieving a perfect airtight seal to prevent exposure to oxygen and moisture.

- If your primary focus is safety and tamper-evidence: Induction sealing is the superior choice, as the foil liner provides clear, visual proof that the product is secure.

- If your primary focus is preventing leaks: The goal is a strong, permanent bond created by either direct heat or induction sealing that can withstand the pressures of shipping and handling.

Ultimately, the function of a sealing machine is to deliver on the promise of the product contained within the package.

Summary Table:

| Sealing Goal | Recommended Method | Key Benefit |

|---|---|---|

| Product Freshness & Shelf Life | Airtight Heat Sealing | Blocks oxygen and moisture to prevent spoilage. |

| Safety & Tamper-Evidence | Induction Sealing | Provides a clear, visual seal that deters tampering. |

| Leak Prevention | Strong Heat/Induction Bond | Creates a durable seal that withstands shipping pressures. |

Need a reliable sealing solution for your commercial operation? HONESTBEE supplies high-performance sealing machines and equipment to commercial apiaries and beekeeping equipment distributors. We help you guarantee product integrity, extend shelf life, and protect your brand reputation. Contact our wholesale experts today to find the perfect sealing equipment for your needs!

Visual Guide

Related Products

- Handheld Induction Sealing Machine for Tamper Evident Packaging

- Automatic Continuous Heat Sealing Machine

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Semi Automatic Round Bottle Labeling Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

People Also Ask

- What is a sealing machine called? Choose the Right Heat Sealer for Your Packaging

- How does a well-sealed jar contribute to extending the shelf life of honey? Master Long-Term Honey Preservation

- What is the function of semi-automatic heat shrink packaging machines in a glass jar reuse facility? Protect Your Inventory

- How do you package honey safely? Protect Your Harvest from Moisture and Contamination

- How do light-proof and anti-oxidation sealing machines maintain the quality of Royal Jelly? Protect Bioactive 10-HDA

- How does an induction sealing machine work? Enhance Honey Packaging with Hermetic Seals & Tamper Evidence

- What cleaning practices are crucial for the effective sealing of honey jars? Ensure Maximum Product Shelf Life

- What defines a 3-side seal on a stick pack? Unlock the Benefits of Efficient Folded Packaging