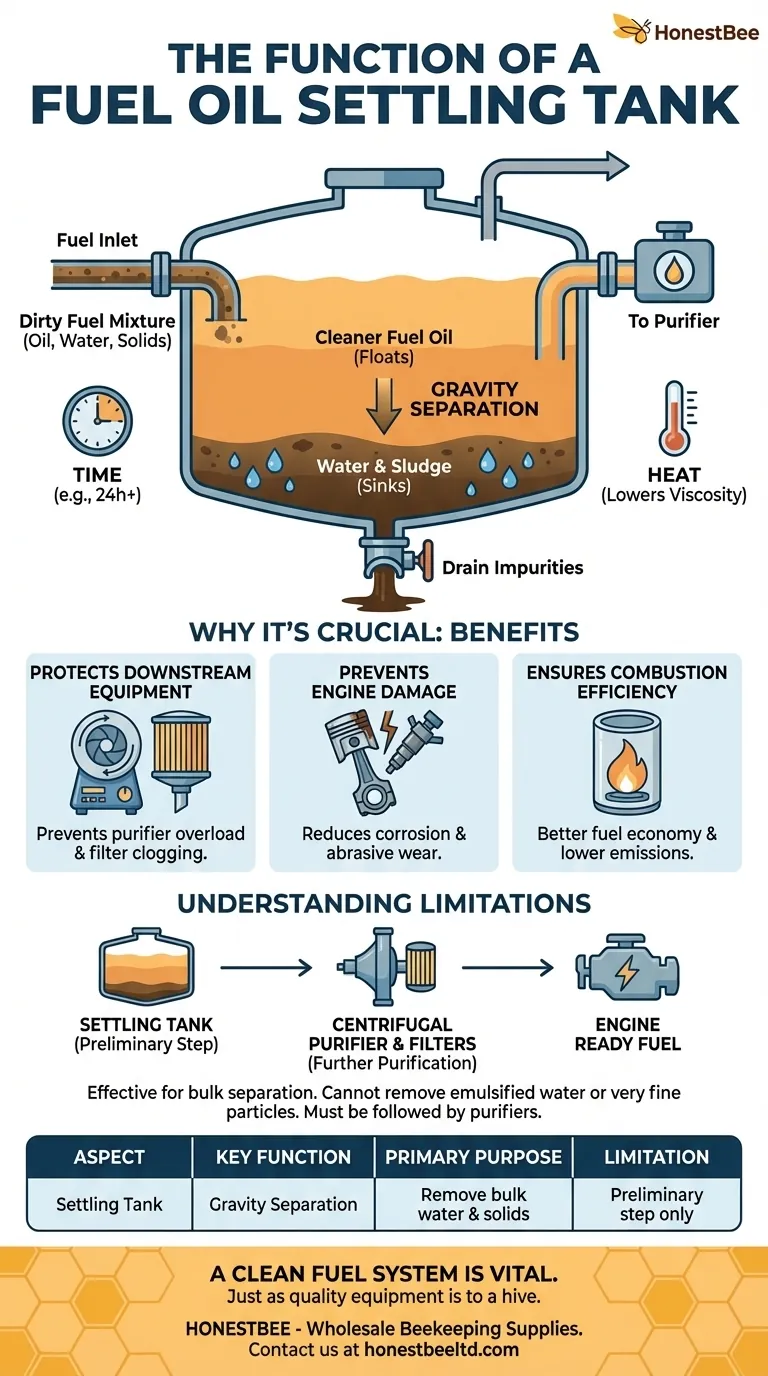

The primary function of a settling tank is to act as the first stage of fuel oil purification. It is a large tank designed to allow contaminants like water and solid particles to naturally separate from the fuel through the simple force of gravity before the fuel undergoes more intensive cleaning.

A settling tank is not merely for storage; it is an active pre-cleaning system. Its core purpose is to use gravity and time to remove the heaviest and most obvious impurities from fuel oil, significantly reducing the burden on more sensitive downstream purification equipment and protecting the engine.

The Core Principle: Separation by Gravity

A settling tank operates on a straightforward yet critical principle: different substances within a liquid mixture will separate based on their density.

Leveraging Density Differences

Fuel oil is less dense than water and most solid contaminants like sludge, rust, or sand. When this mixture is left undisturbed in a tank, the heavier elements naturally sink to the bottom.

The Role of Time and Temperature

This separation process is not instantaneous. It requires a significant amount of time, often 24 hours or more, for the "settling" to occur effectively. To speed up the process, the fuel oil inside the tank is often heated, which lowers its viscosity (makes it less "thick") and allows water and solids to fall more easily.

Draining the Impurities

The collected water and sludge accumulate at the bottom of the tank. These impurities are then periodically drained off, leaving the cleaner fuel oil at the top to be transferred for the next stage of purification.

Why This Pre-Cleaning Step is Crucial

Failing to use a settling tank effectively would introduce a host of severe problems into a vessel's fuel system and machinery.

Protecting Downstream Equipment

The settling tank is the first line of defense. By removing the bulk of water and sludge, it prevents purifiers (centrifuges) and fine filters from becoming overwhelmed or clogged, allowing them to work more efficiently on removing smaller contaminants.

Preventing Engine Damage

Water in fuel can lead to severe corrosion of engine components, poor combustion, and even microbiological growth. Abrasive solid particles cause significant wear and tear on fuel pumps, injectors, and cylinder liners, leading to costly and premature failures.

Ensuring Combustion Efficiency

Cleaner fuel results in better atomization and more complete combustion inside the engine. This directly translates to improved fuel efficiency, more power output, and reduced harmful emissions.

Understanding the Limitations

While essential, a settling tank is only part of the solution and has inherent limitations. It is a coarse, bulk-separation method.

It Is a Preliminary Step

Gravity settling can only remove impurities that are significantly denser than the fuel. It is ineffective against very fine solids or water that has become emulsified (chemically bonded) with the fuel.

The Need for Further Purification

The fuel drawn from the top of the settling tank is cleaner, but it is not clean enough for a modern engine. It must always be processed further by a centrifugal purifier and a series of filters to remove the remaining microscopic contaminants.

Key Operational Takeaways

To use this component effectively, consider its role in the larger system.

- If your primary focus is maximum engine protection: Treat the settling tank as the indispensable first stage of purification. Always allow for adequate settling time and never bypass this step.

- If your primary focus is operational efficiency: Regularly drain water and sludge from the tank bottom to prevent re-contamination and reduce the workload on your purifiers.

- If your primary focus is fuel quality management: Use the drain samples from the settling tank as the first and best indicator of the quality of the fuel you have received.

This seemingly simple tank is a critical safeguard for the health and efficiency of the entire propulsion system.

Summary Table:

| Aspect | Key Function |

|---|---|

| Primary Purpose | First-stage purification via gravity separation. |

| Removes | Bulk water and solid particles (sludge, rust). |

| Protects | Downstream purifiers, filters, and the main engine. |

| Limitation | Preliminary step; cannot remove emulsified water or fine particles. |

Protect your vessel's engine and improve fuel efficiency with the right purification equipment. HONESTBEE supplies high-quality beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. A clean fuel system is as vital to an engine as quality equipment is to a hive. Ensure your operations run smoothly. Contact HONESTBEE today to discuss your wholesale equipment needs.

Visual Guide

Related Products

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Uncapping Tank with Stand and Strainer

People Also Ask

- What are the mechanisms and benefits of using filtration and settling tanks in honey processing? Boost Quality.

- How does a Honey Settling Tank improve the sensory quality of the final honey product? Ensure Clarity and Purity

- How does the depth of the honeycomb affect the choice of uncapping tool? Match the Right Gear for Maximum Efficiency

- What role does an uncapping table play in the initial stages of honey processing? Boost Your Extraction Efficiency

- What role does a honey settling tank play in the quality control of honey products? Ensure Premium Purity and Clarity

- How long to leave honey in a settling tank? Optimize Your Clarification Process

- What is the purpose of a settling tank or de-aerator in honey clarification? Achieve Professional Liquid Clarity

- What methods can small-scale or hobbyist beekeepers use to uncap honey frames? Top 6 Efficient Techniques