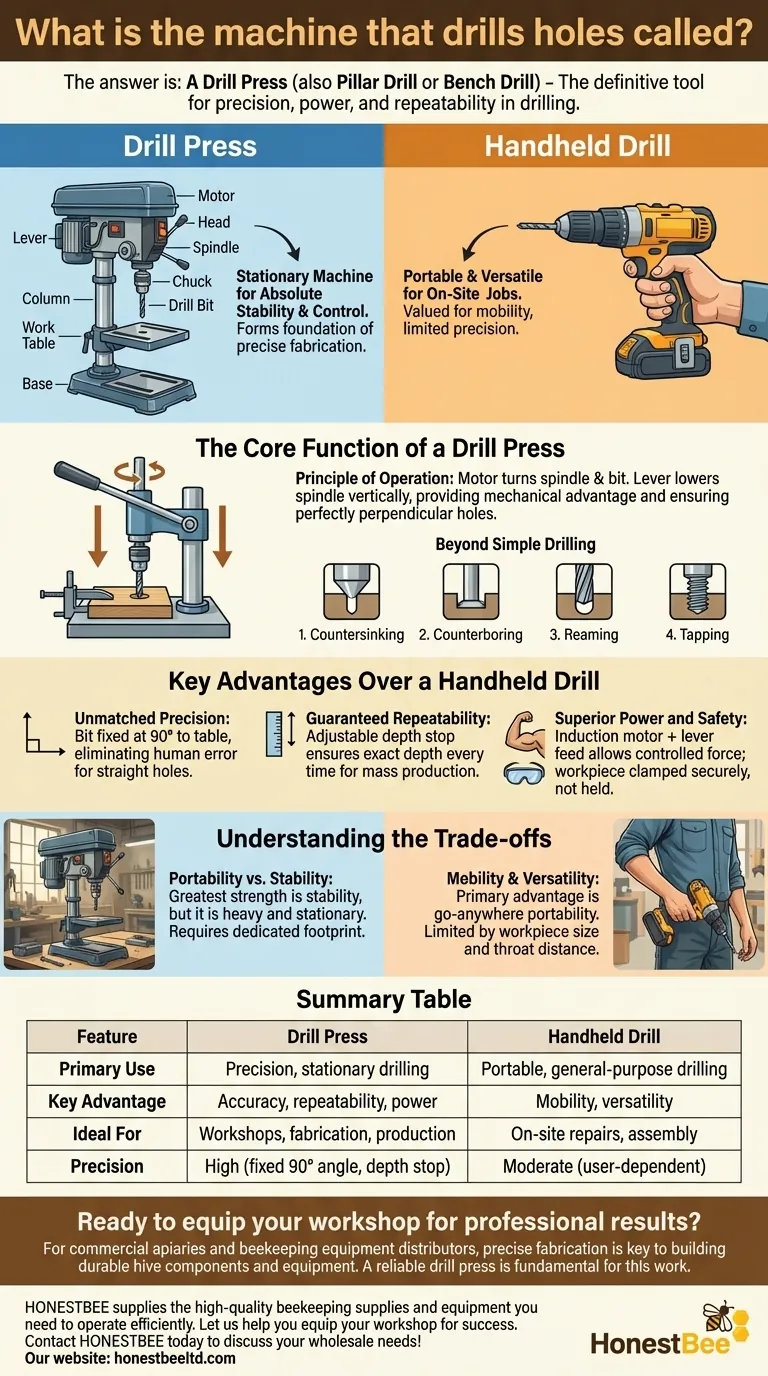

In a workshop, the stationary machine designed specifically for drilling holes is called a drill press. Also known as a pillar drill or bench drill, this machine provides a level of precision, power, and repeatability that a handheld drill cannot match. It works by turning a cutting tool (like a drill bit) and advancing it into a secured workpiece.

While a handheld drill is valued for its portability, a drill press is the definitive tool for drilling perfectly straight and consistently placed holes. It trades mobility for absolute stability and control, forming the foundation of precise fabrication in both woodworking and metalworking.

The Core Function of a Drill Press

A drill press is fundamentally a simple machine, but its design is what provides its significant advantages. It consists of a base, a vertical column (or pillar), an adjustable work table, and a head containing the motor and spindle.

The Principle of Operation

The motor turns a spindle, which holds the drill bit inside a chuck. The user pulls a lever attached to the head, which lowers the entire rotating spindle assembly vertically into the workpiece clamped on the table. This mechanism provides significant mechanical advantage and ensures the hole is perfectly perpendicular to the work surface.

Beyond Simple Drilling

While its primary function is drilling holes, a drill press is a versatile machining tool. With the correct bits and accessories, it can perform several other essential operations with the same level of precision.

These include countersinking (creating a cone-shaped opening for a screw head), counterboring (creating a flat-bottomed recess for a bolt head), reaming (enlarging and finishing an existing hole to an exact size), and tapping (cutting internal threads).

Key Advantages Over a Handheld Drill

The reason a dedicated workshop cannot function without a drill press comes down to three critical advantages that a handheld tool can never guarantee.

Unmatched Precision

The drill bit is held at a fixed 90-degree angle to the table. This eliminates human error and ensures every hole is perfectly straight, which is critical for strong joinery and professional-looking results.

Guaranteed Repeatability

Drill presses feature an adjustable depth stop. This allows you to set the exact depth of a hole and repeat it flawlessly across dozens or hundreds of pieces. This is impossible to achieve consistently by eye with a handheld drill.

Superior Power and Safety

The combination of a powerful induction motor and a lever-based feed system allows you to apply significant, controlled force. This makes drilling into dense hardwoods or thick metal far easier and safer, as the workpiece is securely clamped to the table rather than being held by hand.

Understanding the Trade-offs

Choosing between a drill press and a handheld drill is not about which is "better," but which is appropriate for the task at hand. The drill press is a specialized tool with clear limitations.

Portability vs. Stability

The greatest strength of a drill press is its stability, which comes from being heavy and stationary. It cannot be brought to a project, such as assembling furniture or hanging a picture on a wall. A handheld drill's primary advantage is its go-anywhere portability.

Footprint and Cost

A drill press requires dedicated space in a workshop, either on a bench (for a benchtop model) or on the floor (for a larger floor model). It is a more significant financial investment than a handheld drill.

Workpiece Size

The size of the material you can work with is limited by the "throat" of the drill press—the distance between the column and the spindle. Very large or awkwardly shaped pieces may not fit, making a handheld drill the only option.

Making the Right Choice for Your Goal

Selecting the correct tool is the first step toward a successful project. Your decision should be guided entirely by the requirements of the task.

- If your primary focus is general household repairs and assembly: A quality handheld drill is the correct and most versatile choice.

- If your primary focus is precision woodworking or metalworking: A drill press is an essential, non-negotiable machine for accurate and repeatable results.

- If you are setting up a new workshop and need a foundational tool: A benchtop drill press provides a massive leap in capability over any handheld alternative.

Understanding this distinction empowers you to choose the right tool for the job, moving from simple tasks to precise, repeatable fabrication.

Summary Table:

| Feature | Drill Press | Handheld Drill |

|---|---|---|

| Primary Use | Precision, stationary drilling | Portable, general-purpose drilling |

| Key Advantage | Accuracy, repeatability, power | Mobility, versatility |

| Ideal For | Workshops, fabrication, production | On-site repairs, assembly |

| Precision | High (fixed 90° angle, depth stop) | Moderate (user-dependent) |

Ready to equip your workshop for professional results?

For commercial apiaries and beekeeping equipment distributors, precise fabrication is key to building durable hive components and equipment. A reliable drill press is fundamental for this work.

HONESTBEE supplies the high-quality beekeeping supplies and equipment you need to operate efficiently. Let us help you equip your workshop for success.

Contact HONESTBEE today to discuss your wholesale needs!

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Jack Type Honey Comb Press Machine Wax and Honey Separator

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- What are the material advantages of using a stainless steel honey press? Ensure Pure, Lead-Free Honey Extraction

- How does pressed honey compare to extracted or crush-and-strain? Unlock the Full Flavor of the Hive

- What are the advantages of using industrial-grade stainless steel honey extractors vs. traditional methods?

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- What are the main differences between centrifugal extractors and honey presses? A Guide for Commercial Apiaries