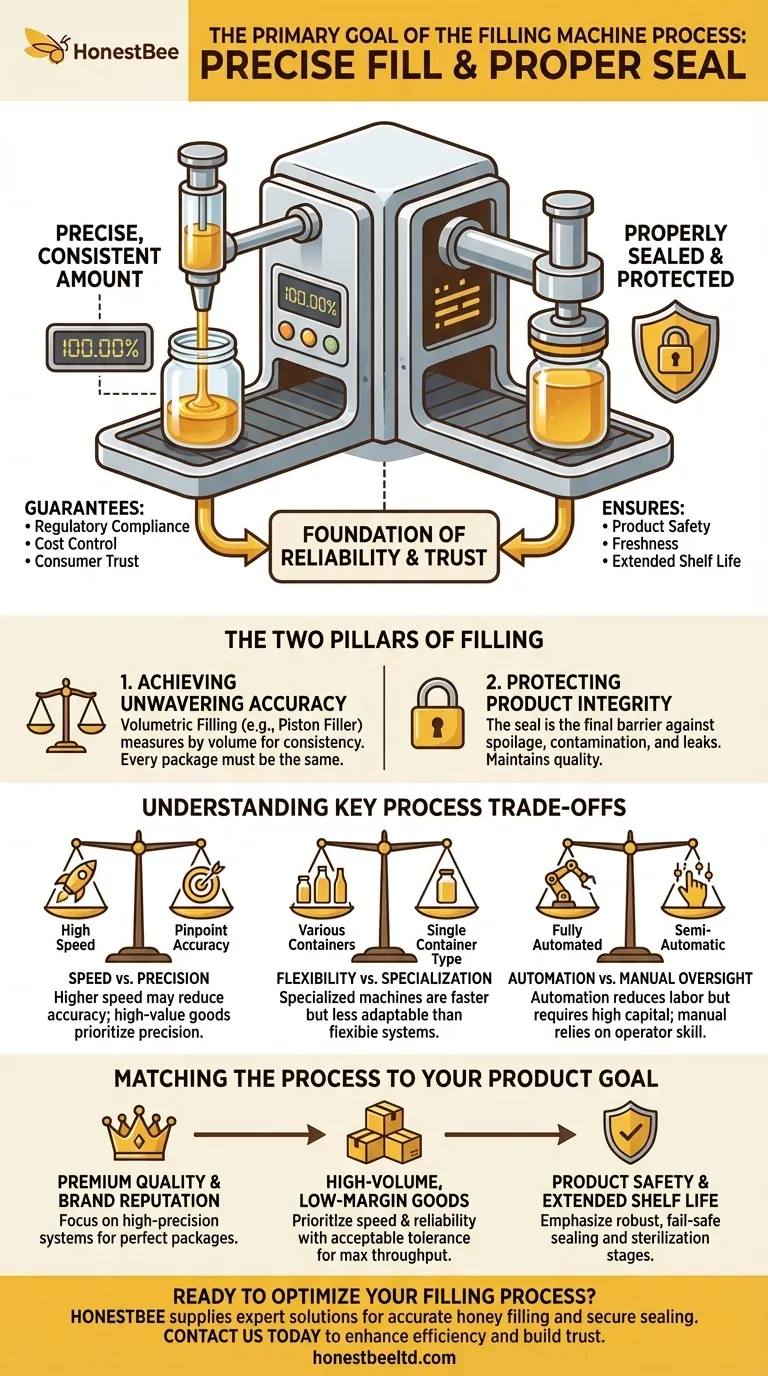

The primary goal of any filling machine process is to ensure every container is filled with a precise, consistent amount of product and then sealed properly. This dual function is fundamental to guaranteeing product quality, consumer trust, and operational efficiency.

The core objective extends beyond simple mechanics; it's about establishing reliability. An effective filling process ensures the customer gets exactly what they paid for, while the product itself remains safe, sterile, and preserved until use.

The Two Pillars of Filling: Accuracy and Integrity

The entire filling operation is built upon two non-negotiable principles. The first is delivering the correct amount of product, and the second is protecting that product from the outside world.

Achieving Unwavering Accuracy

Accuracy is paramount for several reasons. It ensures regulatory compliance with weights and measures laws, controls costs by preventing product "giveaway," and builds brand reputation by providing a consistent consumer experience.

Every package that leaves the line must contain the same amount of product as the one before it.

How Machines Guarantee Precision

To achieve this consistency, machines often use precise measurement techniques. A common method is volumetric filling, which measures product by volume rather than weight.

For example, a piston filler draws a specific, repeatable volume of a product (like honey or sauce) into a cylinder and then dispenses that exact amount into the container.

The Critical Role of Proper Sealing

Once the container is accurately filled, it must be sealed to protect its contents. An improper seal can lead to leaks, spoilage, contamination, and a significantly reduced shelf life.

Protecting Product Integrity

The seal is the final barrier between the product and the external environment. It maintains freshness, ensures safety from bacteria or debris, and can provide tamper-evident features that give consumers peace of mind.

Understanding Key Process Trade-offs

Selecting or designing a filling process involves balancing competing priorities. Understanding these trade-offs is crucial for aligning the machinery with business goals.

Speed vs. Precision

Increasing the speed of a filling line can sometimes come at the cost of pinpoint accuracy. For high-value products, manufacturers often prioritize precision over maximum speed to minimize costly waste.

Flexibility vs. Specialization

A machine designed to fill only one type of container will typically be faster and more reliable than a flexible system that must be reconfigured for various shapes and sizes. Specialization offers efficiency, while flexibility supports a wider product range.

Automation vs. Manual Oversight

Fully automated systems reduce labor costs and human error but require a significant capital investment. Semi-automatic processes offer a lower entry cost but depend on operator skill for consistency and quality control.

Matching the Process to Your Product Goal

The ideal filling strategy depends entirely on your primary objective.

- If your primary focus is brand reputation and premium quality: Invest in high-precision systems to eliminate variation and ensure every single package is perfect.

- If your primary focus is high-volume, low-margin goods: Prioritize machines built for speed and reliability, accepting a slightly wider (but still legal) tolerance for fill accuracy to maximize throughput.

- If your primary focus is product safety and extended shelf life: Emphasize the sealing, capping, or sterilization stages of the process, ensuring they are robust and fail-safe.

Ultimately, a well-designed filling process is the foundation of operational efficiency and customer trust.

Summary Table:

| Key Aspect | Core Objective | Why It Matters |

|---|---|---|

| Fill Accuracy | Deliver the exact, consistent amount of product. | Ensures regulatory compliance, cost control, and consumer trust. |

| Sealing Integrity | Protect the product from contamination and spoilage. | Maintains product safety, freshness, and extends shelf life. |

| Process Trade-offs | Balance speed, precision, flexibility, and automation. | Aligns machinery with business goals like volume or premium quality. |

Ready to optimize your filling process for maximum precision and efficiency?

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. Our expertise ensures you get the right machinery for accurate honey filling, secure sealing, and streamlined production—whether your priority is high-volume output or premium product integrity.

Contact us today to discuss how our solutions can enhance your operational efficiency and build unwavering customer trust.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- In what ways do automatic honey-filling machines enhance honey post-processing? Scale Efficiency and Profitability

- What types of machines are used for honey packaging? Build an Efficient Line for Your Scale

- What technical advantages do automated honey filling machines offer? Scale Your Apiary with Industrial Precision

- How do automated honey-filling machines enhance product quality? Advanced Precision for Commercial Apiaries

- Why must honey filling and storage equipment be inert and airtight? Preserve Bioactive Potency & Commercial Quality

- How do industrial honey-filling machines maintain the quality of honey? 5 Key Technologies for Pure Product Integrity

- What additional support is available for selecting a honey packaging machine? Get Expert Guidance for Your Apiary

- What makes semi-automatic filling machines versatile? A Flexible Solution for Growing Businesses