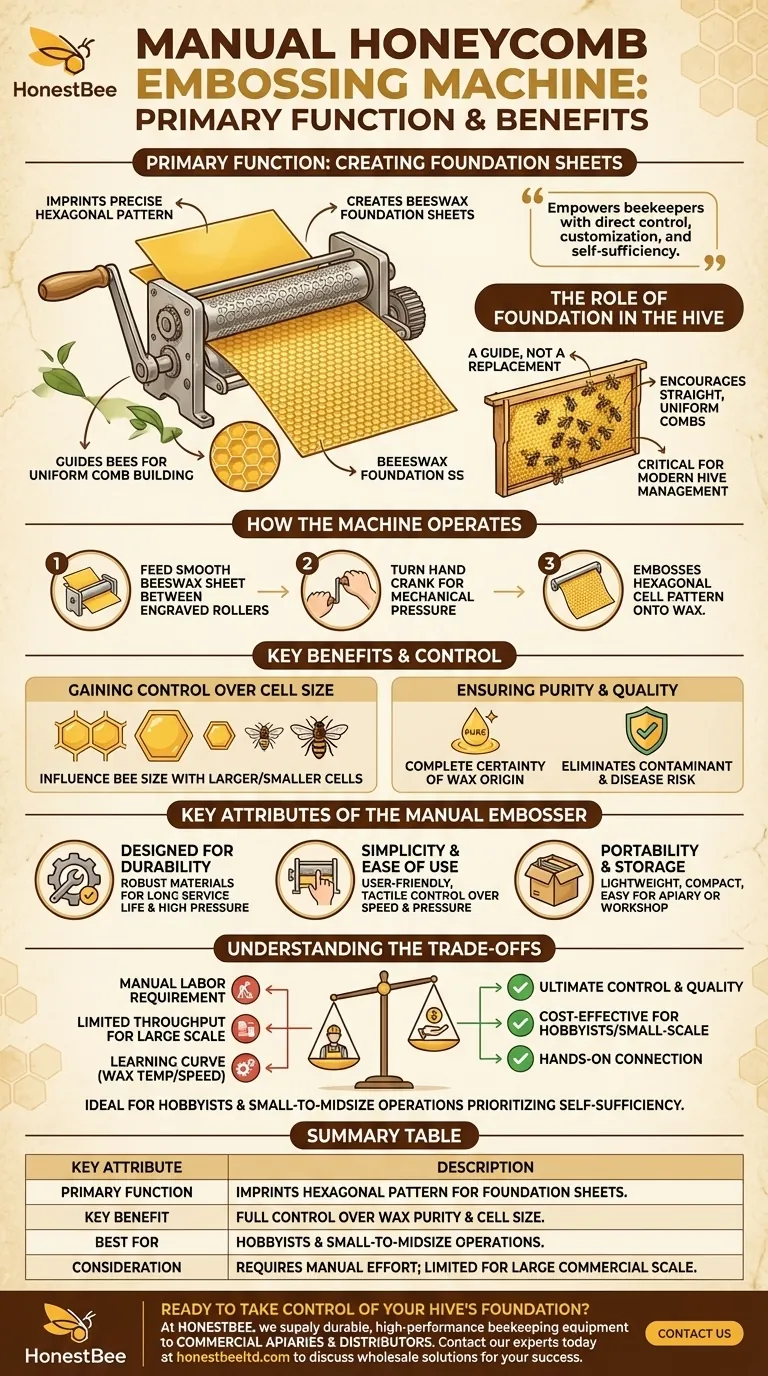

At its core, the primary function of a manual honeycomb embossing machine is to imprint a precise hexagonal honeycomb pattern onto sheets of beeswax. This creates what beekeepers call "foundation sheets," which provide a guide for bees to build their comb within a hive frame.

This machine moves beyond simple function; it empowers beekeepers with direct control over the very foundation of their hives, enabling customization and self-sufficiency in a critical aspect of apiary management.

The Role of Foundation in the Hive

Beeswax foundation is a guide, not a replacement for the bees' own work. Providing them with a pre-patterned sheet of wax encourages them to build straight, uniform combs inside the removable frames of a modern hive.

How the Machine Operates

The process is fundamentally mechanical. A beekeeper feeds a smooth sheet of beeswax between two engraved rollers. By turning a hand crank, the rollers press into the wax, embossing it with the hexagonal cell pattern.

Gaining Control Over Cell Size

One of the key benefits is the ability to influence the size of the honeycomb cells. Some beekeepers believe that using foundation with slightly smaller or larger cells can influence the size of the bees that are raised, a technique used in certain management practices.

Ensuring Purity and Quality

By creating your own foundation sheets, you have complete certainty about the purity of the wax. This eliminates the risk of introducing contaminants or diseases that can sometimes be present in commercially sourced foundation.

Key Attributes of the Manual Embosser

These machines are designed with the practical needs of the beekeeper in mind, balancing functionality with usability.

Designed for Durability

The embossing process requires significant pressure. These machines are typically built with robust, durable materials to withstand this force repeatedly, ensuring a long service life with minimal maintenance required.

Simplicity and Ease of Use

A manual embosser is intentionally user-friendly. It requires little setup and is operated by hand, giving the beekeeper full tactile control over the speed and pressure of the embossing process.

Portability and Convenient Storage

Their design is often lightweight and compact. This makes the machine easy to transport for use at an apiary or in a workshop, and it allows for simple storage when not in use.

Understanding the Trade-offs

While highly effective, a manual machine comes with inherent limitations that are important to consider.

Manual Labor Requirement

The most obvious trade-off is the physical effort required. Unlike electric models, a manual machine relies entirely on your power to operate. For a small number of sheets, this is negligible, but for larger batches, it can become a significant workout.

Throughput and Scale

A manual embosser is perfectly suited for hobbyists or small-to-midsize beekeeping operations. However, for large commercial apiaries that need to process thousands of sheets, the manual process would be too slow and labor-intensive to be practical.

The Learning Curve

While the machine is simple, producing a perfect foundation sheet takes a bit of practice. Learning the right wax temperature, rolling speed, and pressure to avoid tearing or incomplete patterns is part of the process.

Making the Right Choice for Your Goal

Deciding if a manual embosser fits your needs depends on the scale and philosophy of your beekeeping.

- If your primary focus is self-sufficiency and foundation purity: This machine gives you ultimate control over the quality and characteristics of your hive's foundation.

- If your primary focus is hobby or small-scale beekeeping: Its ease of use, portability, and low maintenance make it an excellent and cost-effective tool.

- If your primary focus is large-scale commercial production: The manual effort will likely create a bottleneck, and you should investigate automated or electric alternatives.

Ultimately, this machine provides a direct, hands-on connection to a fundamental element of your bees' world.

Summary Table:

| Key Attribute | Description |

|---|---|

| Primary Function | Imprints a hexagonal honeycomb pattern onto beeswax to create foundation sheets. |

| Key Benefit | Full control over wax purity and cell size for customized hive management. |

| Best For | Hobbyists and small-to-midsize beekeeping operations prioritizing self-sufficiency. |

| Consideration | Requires manual effort; throughput may be limited for large-scale commercial use. |

Ready to take control of your hive's foundation with pure, custom-made wax sheets?

At HONESTBEE, we supply durable, high-performance beekeeping equipment to commercial apiaries and distributors. Our manual honeycomb embossing machines are built for longevity and precision, empowering you to produce high-quality foundation with complete certainty.

Contact our experts today to discuss how our wholesale-focused operations can support your beekeeping success.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How do fully automatic wax foundation machines save time for beekeepers? Boost Your Apiary's Efficiency & Scale

- How does the cutting cylinder with a timed cut-off function enable automated beeswax foundation production? Effortless Consistency

- What is the role of professional beeswax processing equipment? Achieve Diversified Outputs for Beekeeping Enterprises

- What is the physical structure of the manual wax roller? Durable Cast Iron and Fixed Roller Design Explained

- What is the function of a manual tablet press machine in beeswax processing? Create Pure, Plain Wax Sheets with Ease

- What is the function of foundation sheet processing machinery? Boost Honey Yields and Bee Efficiency

- How does the hygiene management of beeswax refineries contribute to Small Hive Beetle control? Secure Your Region.

- How do fully automatic wax foundation machines increase production efficiency? Scale Your Apiary Fast