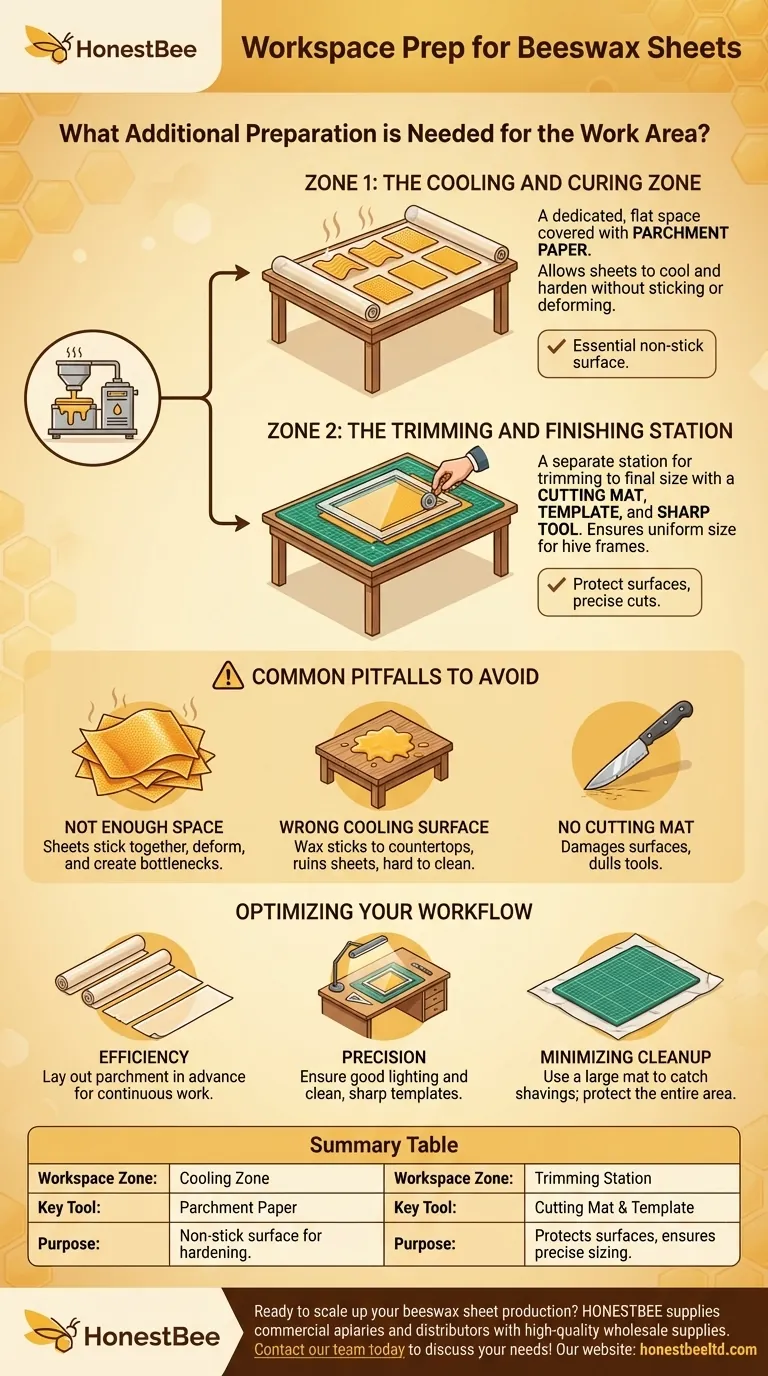

In addition to your primary melting and molding equipment, preparing your work area for making beeswax sheets requires two key additions. You must set up a dedicated space covered with parchment paper for the finished sheets to cool, and a separate station for trimming the cooled sheets to their final size using a cutting mat and template.

The core challenge in making beeswax sheets is managing the transition from hot, pliable wax to a cool, finished product. A properly prepared workspace anticipates this workflow with distinct zones for cooling and cutting, ensuring a clean process and uniform results.

Setting Up Your Workspace for Success

A well-organized space is crucial for an efficient and mess-free production process. Your setup should be arranged like a small assembly line: from molding, to cooling, to final trimming.

The Cooling and Curing Zone

Once a sheet is formed, it will still be warm and slightly soft. You cannot stack these sheets or place them on a standard countertop without them sticking or deforming.

You need a large, flat area next to your primary workspace designated for cooling. Cover this surface with parchment paper.

The parchment paper provides an essential non-stick surface, allowing the sheets to cool and harden fully without adhering to your table. Ensure you have enough space to lay each sheet out individually.

The Trimming and Finishing Station

Raw beeswax sheets are often oversized or have uneven edges. They must be cut to precise dimensions to fit correctly into a hive frame.

This requires a dedicated cutting station with three key tools: a cutting mat, a template, and a sharp cutting tool.

The cutting mat protects your work surface from knife scores. The template, typically made to the exact size of your hive frame's interior, ensures every sheet is uniform. A sharp knife or pizza cutter provides the cleanest and most accurate cut.

Common Pitfalls in Workspace Preparation

Failing to prepare these secondary areas is a common mistake that leads to frustration and subpar results. Understanding these pitfalls will help you avoid them.

Not Allocating Enough Space

Beeswax sheets cannot be stacked until they are completely cool and hard. Trying to work in a cramped space will lead to sheets sticking together, getting damaged, and creating a bottleneck in your process.

Using the Wrong Cooling Surface

Placing warm wax directly on a wood, laminate, or stone countertop will cause it to stick. This not only ruins the sheet but also creates a significant cleanup challenge. Parchment paper is the simplest solution.

Forgetting a Cutting Mat

Attempting to trim the wax sheets directly on your table or counter will damage the surface and can dull your cutting tool. A self-healing cutting mat is an inexpensive tool that prevents damage and provides a stable surface for precise cuts.

Making the Right Choice for Your Goal

Before you start melting wax, organize your space according to your primary objective.

- If your primary focus is efficiency: Lay out multiple lengths of parchment paper in advance so you can move from one sheet to the next without pausing.

- If your primary focus is precision: Ensure your cutting station is well-lit and that your template is clean and has sharp, defined edges for tracing.

- If your primary focus is minimizing cleanup: Use a large cutting mat to catch any stray wax shavings and place extra paper or a drop cloth under your entire work area.

A few minutes of thoughtful preparation will transform your workspace into an efficient production line for perfect beeswax sheets.

Summary Table:

| Workspace Zone | Key Tool | Purpose |

|---|---|---|

| Cooling Zone | Parchment Paper | Provides a non-stick surface for sheets to harden without sticking or deforming. |

| Trimming Station | Cutting Mat & Template | Protects surfaces and ensures each sheet is cut to the precise size for your hive frames. |

Ready to scale up your beeswax sheet production? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale supplies needed for efficient, large-scale operations. From durable molds to bulk parchment paper, we provide the reliable equipment for a professional setup. Contact our team today to discuss your wholesale needs and streamline your production process!

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What equipment and tools are needed for making beeswax candles? Master the Melt for Safe, Quality Results

- How do you keep beeswax from sticking to a mold? Master the Water Mist Method for a Perfect Release

- Why is clean wax important for making beeswax candles? Prevent Sputtering Flames and Uneven Burns

- How long should you wait before removing a beeswax candle from the mold? The Key to Perfect Demolding

- What role do specialized Wax Molds play in the professional beekeeping production process? Enhance Apiary Efficiency

- What are the primary economic benefits for commercial apiaries to engage in beeswax candle production? Maximize Profits

- What is the technical significance of Citronella in Beeswax Candles? Master the Science of Functional Repellents

- Can you make candles with 100% pure beeswax? A Guide to Cleaner, Brighter Burning Candles