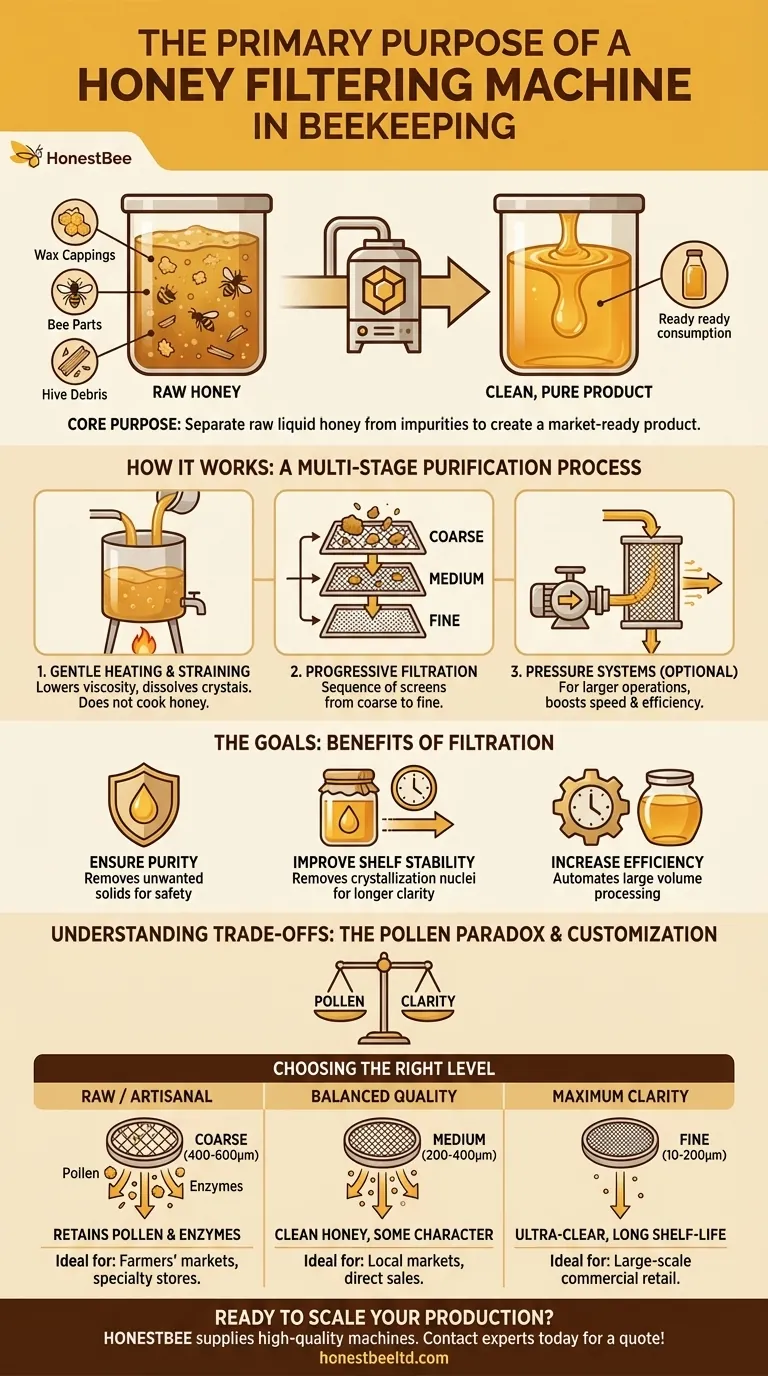

At its core, a honey filtering machine serves one primary purpose: to separate raw liquid honey from physical impurities like wax cappings, bee parts, and other hive debris. This process is the critical step that transforms honey from its harvested state into a clean, pure product ready for bottling and consumption.

The challenge for any beekeeper is that raw honey is naturally full of particles you don't want in the final jar. A filtering machine solves this by systematically removing debris, but the key insight is that the degree of filtration is a deliberate choice that defines the honey's final character, purity, and marketability.

How a Honey Filtering Machine Works

A honey filtering machine is not a single device but a system designed for a multi-stage purification process. The goal is to gently and efficiently clean the honey without damaging its natural qualities.

Initial Straining and Gentle Heating

The process begins after honey is extracted from the comb. The raw honey is typically poured into a tank where it may be gently heated.

This warming doesn't cook the honey; it simply lowers its viscosity and dissolves small sugar crystals, allowing it to flow more easily through the filters.

Progressive Filtration

The core of the machine involves passing the honey through a series of screens or filters. These filters are arranged in a progressive sequence, from coarse to fine.

The first, coarser screen catches large debris like wax chunks and wood splinters. Subsequent, finer mesh screens trap smaller particles, including bee parts and other suspended matter.

The Role of Pressure Systems

For larger commercial operations, some machines incorporate pressure systems. These systems push the honey through the fine filters at a controlled rate, significantly increasing the speed and efficiency of the process.

The Goal: From Raw Honey to a Market-Ready Product

Filtering is not just about cleaning; it's about creating a stable, desirable, and efficient product. The machine directly impacts the quality and value of the final honey.

Ensuring Product Purity

The most obvious goal is removing unwanted solid materials. This ensures the final product is pure honey and nothing else, which is a fundamental requirement for quality control and consumer safety.

Improving Shelf Stability and Appearance

Fine filtering removes tiny particles of wax and pollen that can act as nuclei for crystallization. By removing them, the honey remains liquid and clear for a longer period on the shelf, an appearance many consumers have come to expect.

Increasing Processing Efficiency

For any beekeeper beyond a small-scale hobbyist, filtering by hand is incredibly time-consuming and labor-intensive. A machine automates and streamlines this workflow, processing large volumes of honey quickly and consistently.

Understanding the Trade-offs

While filtering is essential for cleanliness, the intensity of that filtering presents a critical choice for the beekeeper. Aggressive filtering can fundamentally change the nature of the honey.

The "Pollen Paradox"

The central trade-off involves pollen. While consumers may not want to see visible "debris," fine filters that remove all particles also remove most of the naturally occurring pollen.

Pollen is valued by many for its potential nutritional benefits and is used by experts to identify the honey's unique floral source. Over-filtering can strip honey of this distinct character.

Customizing Filtration with Mesh Size

This paradox is managed by choosing the right filter mesh size. Beekeepers can customize their setup to meet specific goals.

A coarse filter (around 400-600 microns) will remove large debris but leave most pollen. A very fine filter (10-200 microns) will produce exceptionally clear honey but remove nearly all pollen.

Market Expectations vs. Natural Character

The final choice often comes down to your target market. Supermarket consumers generally prefer ultra-clear, liquid honey. In contrast, customers at farmers' markets or specialty stores often seek out "raw" or minimally filtered honey, valuing its natural texture and potential for crystallization as signs of authenticity.

Choosing the Right Level of Filtration

Your filtering strategy should align directly with your production goals and the product you want to create.

- If your primary focus is producing "raw" or artisanal honey: Use only coarse straining to remove the largest debris while preserving all the natural pollen and enzymes.

- If your primary focus is large-scale commercial sales: Employ a system with fine filtration to ensure maximum clarity, consistency, and a long shelf life for retail distribution.

- If your primary focus is balancing quality and efficiency for local markets: A medium-mesh filter offers a good compromise, producing clean honey that still retains much of its natural character.

Ultimately, a filtering machine is a tool that gives you precise control over the final character and quality of your honey.

Summary Table:

| Filtration Goal | Filter Mesh Size | Outcome | Ideal For |

|---|---|---|---|

| Raw/Artisanal | Coarse (400-600 microns) | Removes large debris; retains pollen & enzymes | Farmers' markets, specialty stores |

| Balanced Quality | Medium (200-400 microns) | Clean honey with some natural character | Local markets, direct sales |

| Maximum Clarity | Fine (10-200 microns) | Ultra-clear, long shelf-life honey | Large-scale commercial retail |

Ready to scale your honey production with the right filtration system?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, efficient honey filtering machines. We help you choose the perfect system to meet your specific purity, efficiency, and market goals.

Contact our experts today to discuss your needs and get a wholesale quote!

Visual Guide

Related Products

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- Professional Stainless Steel Honey Filtering Machine with Water Bath Heating for Beekeeping

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How does honey filtering and storage equipment affect market value? Maximize Profits with Single-Origin Quality

- What are the benefits of using a honey filtering machine? Boost Purity, Efficiency & Market Appeal

- How do specialized honey collection materials ensure product quality in stingless bee management? Master Pure Harvesting

- How does filtering honey assist beekeepers in complying with regulations? Meet Global Quality & Purity Standards

- What is the role of straining and filtration in beeswax candle manufacturing? Ensure Clean Burns and Premium Quality

- How do you filter honey for bottling? A Guide to Professional Clarity and Quality

- Why is the implementation of mechanized Honey Filtering Machines necessary? Scale Your Honey Quality and Production

- What are the benefits of using a honey filtering machine for bulk processing? Scale Your Apiary with Efficiency & Quality