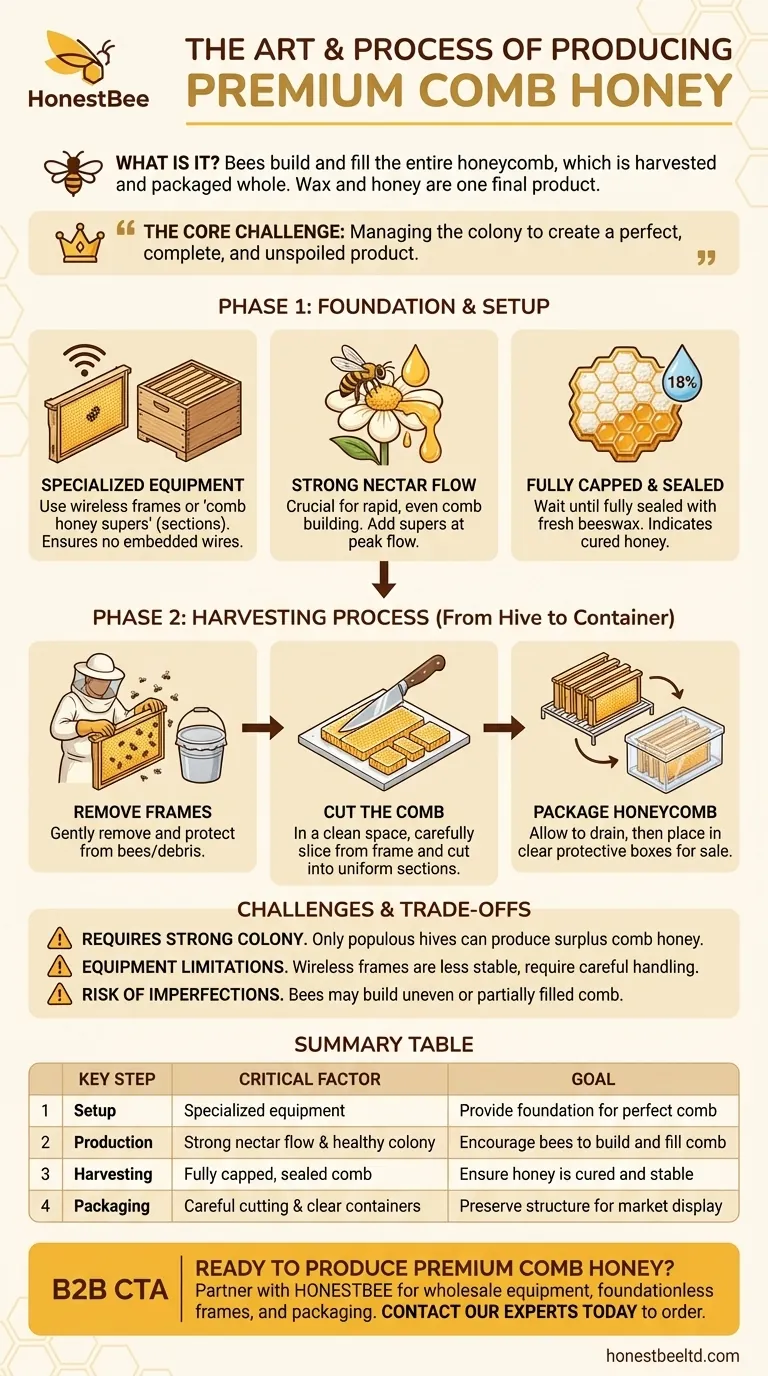

In essence, producing comb honey involves providing bees with specialized equipment and encouraging them to build and fill the entire honeycomb, which is then harvested and packaged whole. This is distinct from extracted honey, as the wax comb itself is part of the final product.

The core challenge of comb honey is not just harvesting, but managing the colony to create a perfect, complete, and unspoiled product. Success depends on using the right equipment, having a strong nectar flow, and harvesting at the precise moment the bees have finished their work.

Understanding the Foundation of Comb Honey

Producing high-quality comb honey means guiding the bees to build the final product for you. This requires specific conditions and hive management that go beyond standard honey production.

The Role of Specialized Equipment

The most common method is cut-comb honey. This works best with frames that have no internal wires.

Beekeepers use frames with a thin, wireless wax foundation or no foundation at all. This ensures that when the comb is cut, there are no wires embedded in the final product.

Some systems also use special "comb honey supers," which are hive boxes filled with small, pre-sized plastic boxes or wooden sections that the bees fill directly.

The Importance of a Strong Nectar Flow

Bees only build new wax comb and store surplus honey when there is an abundance of nectar available.

A beekeeper must add the comb honey supers to a strong, healthy hive at the beginning of a major nectar flow. This gives the bees the resources and motivation to draw out the comb quickly and evenly.

The Critical Moment: Fully Capped Comb

The single most important indicator of readiness is the capping. Bees seal each cell of honey with a fresh layer of white beeswax once the honey is cured to the proper moisture content (around 18%).

A frame must be fully capped and sealed before it is harvested. This ensures the honey will not ferment or spoil and indicates the product is finished.

The Harvesting Process: From Hive to Container

Once the comb is complete, the process of harvesting requires a delicate touch to preserve the pristine structure of the honeycomb.

Step 1: Remove Frames from the Hive

The beekeeper removes the finished frames of comb honey from the hive.

It is crucial to gently brush or blow all the bees off the frames. The frames are then placed in a covered container or bucket to protect them from opportunistic bees and debris.

Step 2: Cut the Comb

This process is done in a clean, sanitary space. For the cut-comb method, the entire sheet of honeycomb is carefully sliced away from the wooden frame.

The large sheet of comb is then cut into smaller, marketable sections. This is often done using a special comb-cutting tool to ensure clean, uniform pieces.

Step 3: Package the Honeycomb

The finished sections of comb honey are allowed to drain of any excess honey from the cut edges.

They are then placed into special clear plastic boxes. This packaging protects the extremely delicate wax comb and beautifully displays the finished product for sale.

Understanding the Trade-offs and Challenges

While rewarding, producing comb honey is more technically demanding than producing liquid honey and comes with a unique set of challenges.

It Requires a Strong, Healthy Colony

Only the most populous and productive hives have the workforce and resources needed to draw out new comb and fill it in a single season. Weak colonies will likely ignore the comb honey supers.

Equipment Limitations

You are limited to using frames without support wires. This can sometimes lead to less stable combs, especially in very hot weather, which requires more careful handling.

The Risk of an Imperfect Product

Bees do not always cooperate perfectly. You may end up with frames that are only partially filled or have uneven, "wavy" comb. These sections are not ideal for premium cut-comb and often must be used for other purposes.

Making the Right Choice for Your Goal

Your approach to comb honey depends entirely on your end goal, whether it's creating a premium product for market or simply enjoying honey in its most natural state.

- If your primary focus is a premium, marketable product: The cut-comb method using foundationless frames is the most reliable path to creating uniform, beautifully packaged comb honey.

- If your primary focus is rustic, personal consumption: Harvesting whole comb from a top-bar hive or foundationless Langstroth frame is simple and provides an authentic experience, even if the shapes are less uniform.

Ultimately, producing comb honey is the art of presenting honey exactly as the bees created it.

Summary Table:

| Key Step | Critical Factor | Goal |

|---|---|---|

| Setup | Specialized equipment (wireless frames/sections) | Provide foundation for perfect comb |

| Production | Strong nectar flow & healthy colony | Encourage bees to build and fill comb |

| Harvesting | Fully capped, sealed comb | Ensure honey is cured and stable |

| Packaging | Careful cutting & clear containers | Preserve structure for market display |

Ready to produce premium comb honey? Equip your commercial apiary or distribution business with the right supplies from HONESTBEE. We provide wholesale-focused beekeeping equipment—including foundationless frames and packaging—to help you succeed. Contact our experts today to discuss your needs and place your order!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

People Also Ask

- Why is a specialized honey filling machine necessary? Meet International Standards and Preserve Premium Honey Quality

- What is the primary function of industrial filling equipment? Maximize Honey Profitability and Market Access

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency