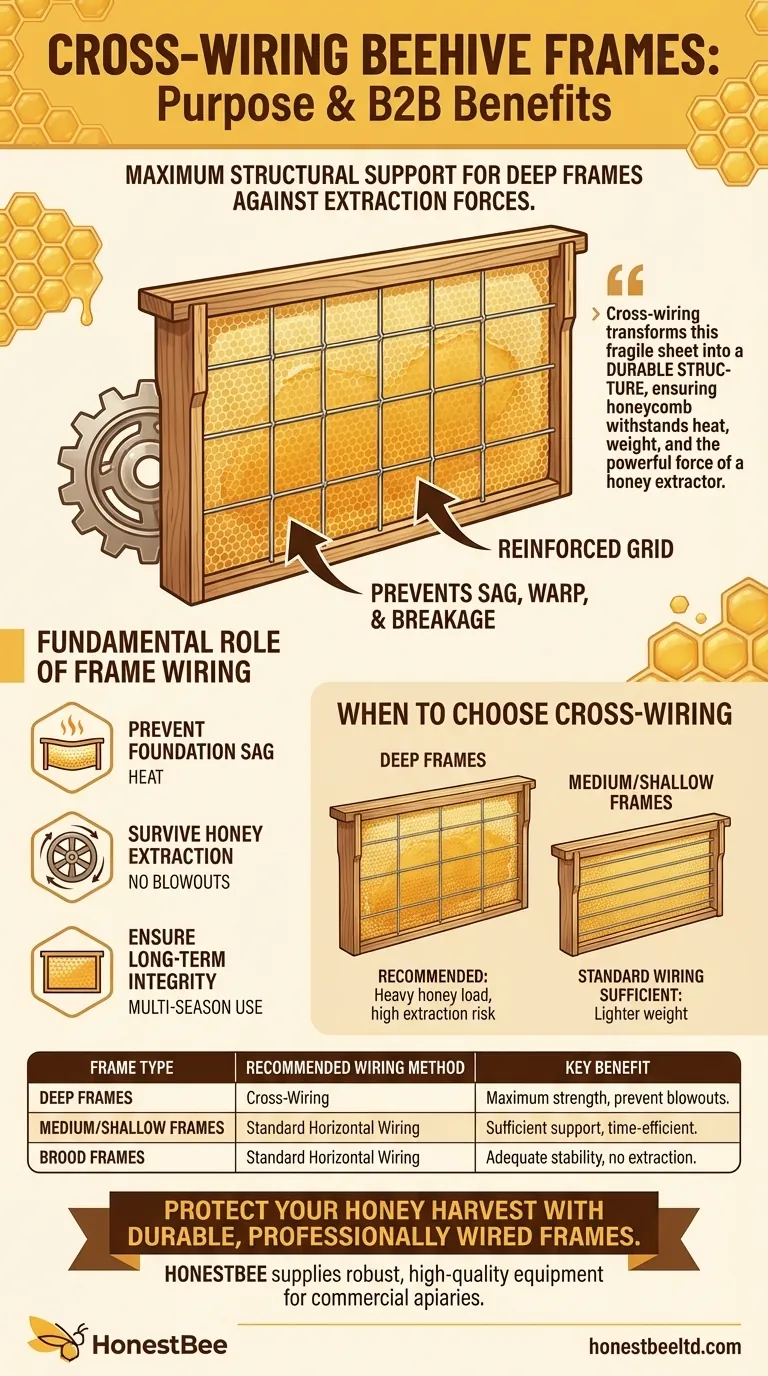

The primary purpose of cross-wiring a beehive frame is to provide maximum structural support. Unlike standard horizontal wiring, cross-wiring uses both vertical and horizontal wires to create a reinforced grid. This method is specifically designed to prevent heavy honeycomb from sagging, warping, or breaking apart, especially under the extreme forces of honey extraction.

A flimsy wax foundation is the single point of failure in a new frame. Cross-wiring transforms this fragile sheet into a durable structure, ensuring the honeycomb bees build upon it can withstand heat, weight, and the powerful force of a honey extractor.

The Fundamental Role of Frame Wiring

Before understanding the specifics of cross-wiring, it's essential to grasp why frames are wired in the first place. A simple sheet of wax or plastic foundation is not strong enough on its own.

Preventing Foundation Sag

Beeswax becomes soft in the high heat and humidity of a hive. Without support, the weight of the bees, brood, and honey can cause the foundation to sag and warp, resulting in poorly drawn, inefficient comb.

Surviving Honey Extraction

The most critical function of wiring is to reinforce the comb for honey harvesting. A honey extractor spins frames at high speed, using centrifugal force to pull the honey out. An unwired frame of honey will almost certainly disintegrate, or "blow out," destroying the comb and wasting the bees' work.

Ensuring Long-Term Frame Integrity

Wired frames are simply more durable. They better withstand the scraping, handling, and general wear and tear of beekeeping over many seasons, making them a better long-term investment.

When to Choose Cross-Wiring Over Standard Wiring

While all frames meant for extraction benefit from wiring, cross-wiring is a specific technique reserved for the most demanding situations.

The Challenge of Deep Frames

The decision to cross-wire is almost entirely dependent on frame size. Deep frames, which hold the most honey and are therefore the heaviest, are the primary candidates for cross-wiring.

Their large surface area and significant weight when full make them much more susceptible to blowouts in an extractor compared to smaller frames.

Creating a Reinforced Grid

Standard wiring only provides horizontal support. Cross-wiring adds vertical wires that intersect the horizontal ones, creating a robust grid. This structure distributes the centrifugal force more evenly across the entire face of the comb, dramatically reducing the risk of collapse.

Understanding the Trade-offs

Cross-wiring is a powerful technique, but it is not a universal solution. Applying it where it isn't needed is inefficient.

Not for Medium or Shallow Frames

Cross-wiring is considered unnecessary for medium or shallow frames. The honeycomb in these smaller frames does not hold enough weight to justify the extra support. Standard horizontal wiring provides more than enough strength for these sizes.

Increased Labor and Complexity

The primary drawback of cross-wiring is the additional time and effort required. Installing both vertical and horizontal wires correctly is more complex and time-consuming than standard wiring, which is a key consideration when preparing a large number of frames.

Making the Right Choice for Your Hive

Choosing your wiring method comes down to the equipment you use and your goals for that equipment.

- If your primary focus is on deep frames for honey supers: Cross-wiring is a strongly recommended practice to protect your comb and maximize your honey harvest without equipment failure.

- If your primary focus is on medium or shallow frames: Standard horizontal wiring provides all the necessary support and is a much more efficient use of your time and resources.

- If your primary focus is on brood chambers (even deep ones): While beneficial, cross-wiring is less critical here as brood frames are not typically put through an extractor.

Ultimately, wiring your frames correctly is a foundational step in ensuring the long-term health and productivity of your hive.

Summary Table:

| Frame Type | Recommended Wiring Method | Key Benefit |

|---|---|---|

| Deep Frames | Cross-Wiring | Maximum strength to prevent blowouts under heavy honey weight. |

| Medium/Shallow Frames | Standard Horizontal Wiring | Sufficient support for lighter comb; more time-efficient. |

| Brood Frames | Standard Horizontal Wiring | Adequate for comb stability; extraction is not a primary concern. |

Protect Your Honey Harvest with Durable, Professionally Wired Frames

As a commercial beekeeper or distributor, a frame failure during extraction means lost honey, lost comb, and lost time. HONESTBEE supplies the robust, high-quality beekeeping equipment you need to operate efficiently at scale.

Our wholesale-focused operations ensure you get durable, reliable frames and foundation built for the demands of commercial apiaries.

Contact HONESTBEE today to discuss your equipment needs and secure your honey harvest.

Visual Guide

Related Products

- Professional Sectional Comb Honey Frame with 250g Cassette System for Beekeeping

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

- Professional 500g Sectional Comb Honey Frame System for Beekeeping

- Professional Wooden Requeening Frame for Beekeeping

People Also Ask

- In what way does a movable frame system enable non-destructive honey harvesting? Boost Efficiency and Colony Health

- What is the structure and function of frames in a beehive? Master Modern Hive Management

- What is the purpose of using a Gridded Wooden Frame? Unlock Precise Data for Brood and Honey Measurement

- What are section comb honey supers? Master Specialized Comb Honey Production with 4 5/8" Equipment

- Why is it important to replace honey frames immediately? Prevent Burr Comb and Protect Hive Architecture