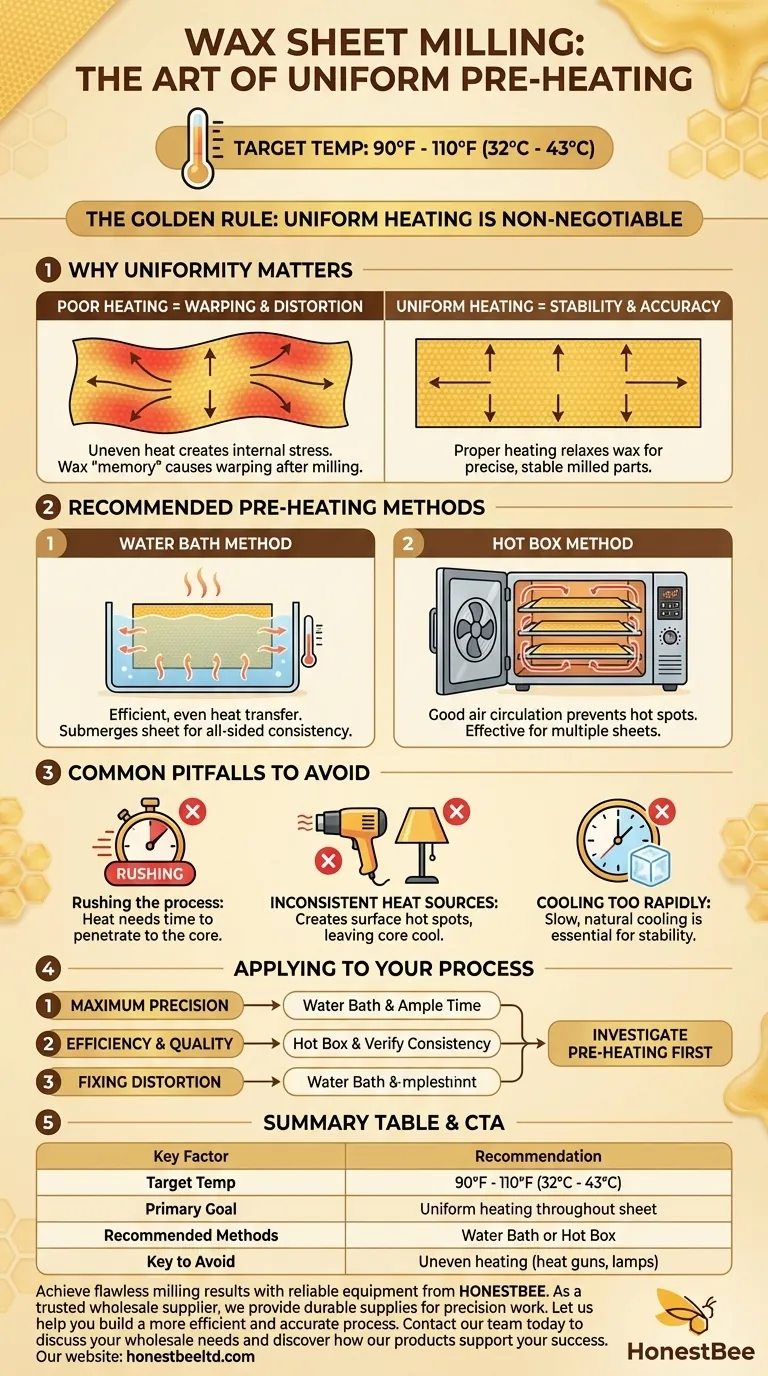

In short, you must pre-heat your wax sheets to a uniform temperature between 90°F and 110°F (32°C - 43°C). Achieving this consistency throughout the entire sheet is just as critical as the temperature itself. The most reliable methods for this are using a thermostat-controlled water bath or a dedicated hot box.

The core challenge isn't just heating the wax, but ensuring every part of it reaches a stable, uniform temperature. This uniformity is the key to preventing internal stress, which is the primary cause of distortion and inaccurate results after milling.

Why Uniform Heating is Non-Negotiable

When wax is milled, the process introduces stress. If the wax is not properly stabilized through uniform heating, this stress will cause it to warp or distort as it returns to room temperature.

The Problem of Internal Stress

Wax has a "memory" of its original state. Heating it properly relaxes this memory and relieves any internal stresses built up during manufacturing or storage.

If you heat a wax sheet unevenly—for example, if the surface is hot but the core is still cool—you are creating a new layer of internal stress. This is a common cause of failure.

The Consequence of Poor Heating

Inaccurate milling is the direct result of improper pre-heating. A part that looks perfect immediately after milling can slowly distort over the next few hours as the trapped stresses are released.

This leads to poor fit, wasted material, and significant time lost having to re-mill the part.

Recommended Pre-Heating Methods

Your goal is to apply gentle, consistent heat throughout the entire volume of the wax sheet. Aggressive or uneven heating is counterproductive.

The Water Bath Method

A thermostat-controlled water bath is an excellent option because water transfers heat very efficiently and evenly. Submerging the sheet ensures it is heated from all sides at the same temperature.

The Hot Box Method

A hot box or a controlled oven is another effective method. The key is to ensure there is good air circulation so that "hot spots" do not develop, which could cause uneven heating.

Common Pitfalls to Avoid

Simply knowing the target temperature is not enough. Avoiding common mistakes is crucial for achieving a predictable and accurate outcome.

Mistake 1: Rushing the Process

Heating must be gradual. The wax needs sufficient time for the heat to penetrate from the surface to the core. A sheet that feels warm on the outside may still be cool internally.

Mistake 2: Using Inconsistent Heat Sources

Avoid using uncontrolled heat sources like heat guns or lamps. These tools create intense hot spots on the surface of the wax while leaving the interior cool, which actively introduces the stress you are trying to eliminate.

Mistake 3: Cooling Too Rapidly

Just as important as uniform heating is uniform cooling. Allowing the milled part to cool slowly and naturally at room temperature is essential for maintaining its dimensional stability.

How to Apply This to Your Process

Your specific approach may vary slightly based on your primary objective.

- If your primary focus is maximum precision: Use a thermostat-controlled water bath and allow ample time for the wax to reach a stable, uniform temperature throughout its thickness.

- If your primary focus is efficiency without sacrificing quality: A hot box can be effective for heating multiple sheets at once, but you must verify its temperature consistency across different shelf locations.

- If you are experiencing distortion in milled parts: The first variable to investigate and correct is your pre-heating procedure, as it is the most common source of the problem.

Ultimately, mastering your pre-heating technique is the foundation for achieving consistently accurate and stable milled wax components.

Summary Table:

| Key Factor | Recommendation |

|---|---|

| Target Temperature | 90°F - 110°F (32°C - 43°C) |

| Primary Goal | Uniform heating throughout the entire sheet |

| Recommended Methods | Thermostat-controlled water bath or dedicated hot box |

| Key to Avoid | Uneven heating from heat guns or lamps |

Achieve flawless milling results with reliable equipment from HONESTBEE.

Proper pre-heating is fundamental, but it starts with using high-quality, consistent wax sheets and reliable milling tools. As a trusted wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable supplies you need for precision work.

Let us help you build a more efficient and accurate process. Contact our team today to discuss your wholesale needs and discover how our products support your success.

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- What is the use of a comb foundation mill? Boost Honey Production with Strategic Hive Control

- What is the purpose of using soap and suds on the roller? Ensure a Clean, Tear-Free Wax Sheet Release

- Why is the wax foundation machine essential for a production cycle? Build a Self-Sufficient Beekeeping Business

- What is the likely cause and solution if a wax sheet feeds crookedly through the mill? Fix Your Dipping Technique

- What is the primary function of the double-roller extrusion system? Master Precision Beeswax Foundation Production

- What happens during the feeding stage of the beeswax flatting and embossing process? Ensure Perfect Foundation Sheets

- What is the function of foundation sheet processing machinery? Boost Honey Yields and Bee Efficiency

- What are the construction features of a manual honeycomb embossing machine? Build Quality and Design Explained