The environmental argument for polyurethane foam hinges on its chemical stability and inertness once it has cured. Because it does not decompose or chemically react with its surroundings, it is considered a durable and stable material that will not leach harmful substances into the soil or air during its long service life.

The term "environmentally friendly" when applied to polyurethane foam refers almost exclusively to its behavior during its use phase. Its primary benefit is its long-lasting, inert nature, which prevents it from breaking down, but this must be weighed against its petroleum-based origin and end-of-life challenges.

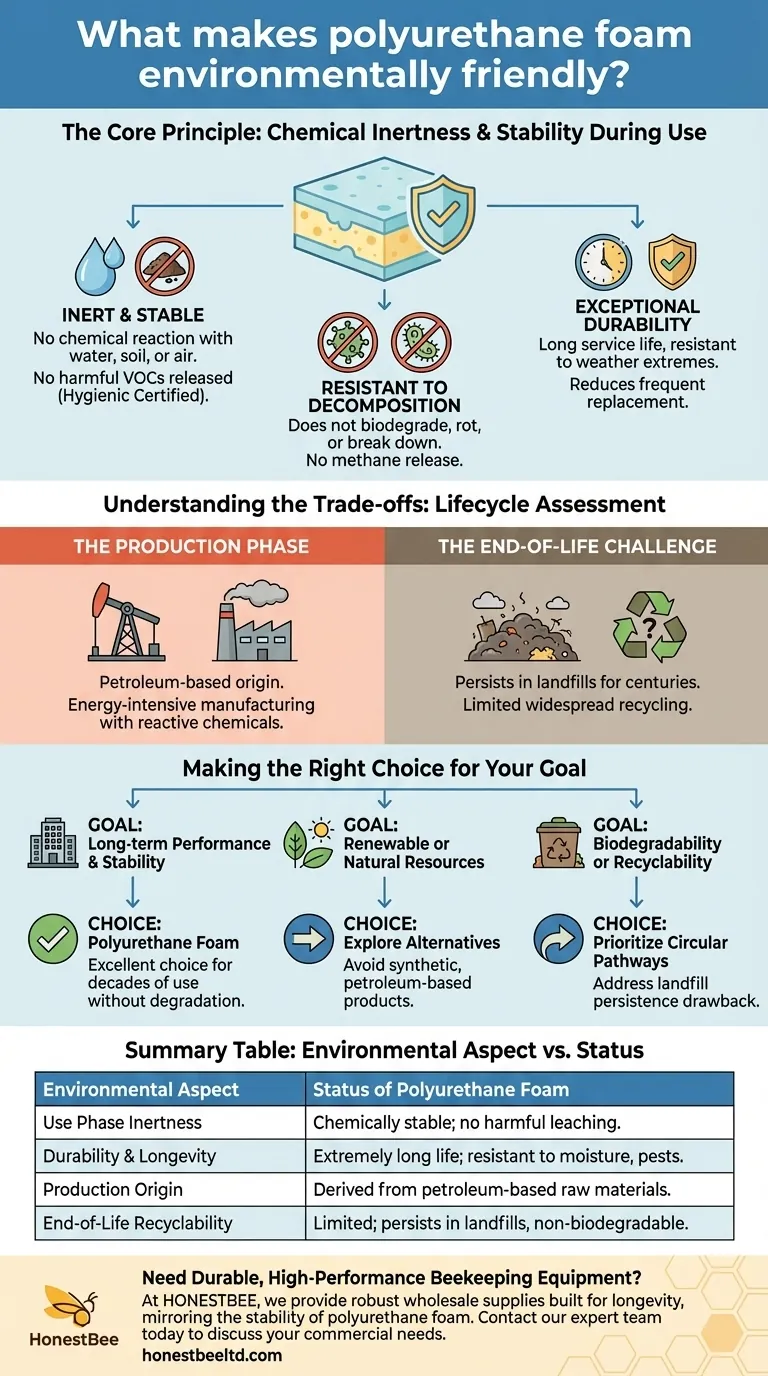

The Core Principle: Chemical Inertness

The central claim for polyurethane foam's environmental benefit is its inertness. After the chemical reaction that creates the foam is complete, the resulting material is a stable, solid plastic.

What "Inert" Means for the Environment

An inert substance is one that is not chemically reactive. For polyurethane foam, this means that once installed and cured, it does not interact with water, soil, or common atmospheric elements.

This stability is confirmed by hygienic certificates which verify that the material is safe for indoor air quality and does not release harmful volatile organic compounds (VOCs) after curing.

Resistance to Decomposition

Unlike organic materials, polyurethane foam does not biodegrade. It is highly resistant to moisture, bacteria, mold, and pests.

This quality prevents it from rotting or breaking down over time, which means it doesn't release methane or other byproducts of decomposition into the environment.

Exceptional Durability and Longevity

The foam's resistance to environmental factors like heat, cold, rain, and ice gives it an extremely long service life.

Because it does not rust, corrode, or decompose, it reduces the need for frequent replacement. This, in turn, minimizes the resource consumption and waste associated with manufacturing and installing new materials.

Understanding the Trade-offs

A balanced assessment requires looking at the material's entire lifecycle. The benefits of its inertness during use are significant, but there are environmental costs in its production and disposal.

The Production Phase

Polyurethane is a polymer derived from petroleum-based raw materials. The extraction and processing of fossil fuels carry a significant environmental footprint.

The manufacturing process itself is energy-intensive and involves handling reactive chemicals that require strict safety and environmental controls.

The End-of-Life Challenge

The foam's key benefit—its resistance to decomposition—becomes its primary environmental drawback at the end of its life.

Because it does not biodegrade, polyurethane foam will persist in a landfill for hundreds of years. While recycling technologies exist, they are not yet widespread, making disposal a major challenge.

Making the Right Choice for Your Goal

To make an informed decision, you must align the material's properties with your project's specific environmental priorities.

- If your primary focus is long-term performance and stability: Polyurethane foam is an excellent choice, as its inert and durable nature ensures it will last for decades without degrading or needing replacement.

- If your primary focus is using renewable or natural resources: You should explore alternatives, as polyurethane foam is a synthetic, petroleum-based product.

- If your primary focus is end-of-life biodegradability or recyclability: The persistence of foam in landfills is a serious drawback, and you may want to prioritize materials with a clearer circular pathway.

Ultimately, understanding that polyurethane foam's "green" credentials are tied to its durability allows you to make a more strategic and responsible material choice.

Summary Table:

| Environmental Aspect | Status of Polyurethane Foam |

|---|---|

| Use Phase Inertness | Chemically stable; does not leach harmful substances. |

| Durability & Longevity | Extremely long service life; resistant to moisture, mold, and pests. |

| Production Origin | Derived from petroleum-based raw materials. |

| End-of-Life Recyclability | Limited; persists in landfills due to non-biodegradability. |

Need Durable, High-Performance Beekeeping Equipment?

At HONESTBEE, we understand that commercial apiaries and distributors need reliable, long-lasting supplies. Just as polyurethane foam's inertness provides stability, our wholesale-focused operations deliver robust beekeeping equipment built for longevity and performance.

Contact our expert team today to discuss your wholesale needs and discover how we can support your business with quality supplies.

Visual Guide

Related Products

- Honey Flow Garden Bee Hive Flow Hive Best Beehive for Beginners

- Goat Skin Leather Bee Sting Proof Beekeeping Gloves with Canvas Sleeve

- Stainless Steel Double Sided Honey Uncapping Fork with Scraper

- Silver Metal Candle Wick Tabs Sustainer Base for Candle Making

- Professional Drop-Style Hive Handles for Beekeeping

People Also Ask

- What are the advantages of synthetic foam for beehives? Improve Humidity Control & Honey Quality

- How long do polystyrene hives last? Decades of Rot-Free Performance with Proper Care

- How does the weight of polystyrene hives compare to that of wooden hives? Lightweight Solutions for Modern Apiaries

- What is the practical value of lightweight beehive materials in migratory beekeeping? Boost Efficiency & Reduce Strain

- What is the function of high-performance insulated beehives? Boost Commercial Apiary Efficiency and Survival

- How does the insulation from Expanded Polystyrene (EPS) hives help bees conserve energy and increase honey production?

- What are the physical advantages of using rigid polyurethane foam (PPU) hives? Maximize Bee Survival in Cold Climates

- What are the advantages of using polystyrene hives in beekeeping? Boost Colony Survival & Honey Yield