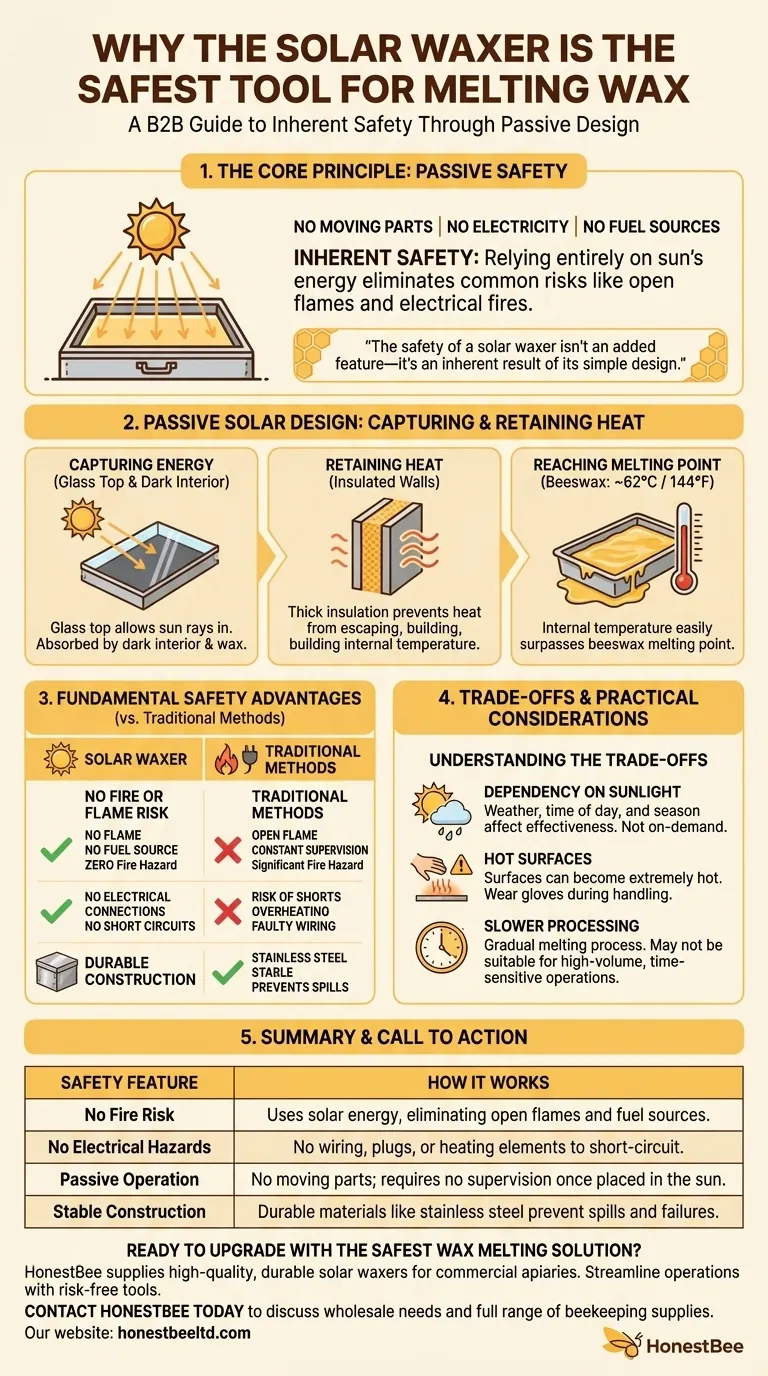

At its core, a solar waxer is safe because it has no moving parts, electrical connections, or fuel sources. It is a passive device that relies entirely on the sun's energy, which fundamentally eliminates the most common risks associated with melting wax, such as open flames and electrical fires.

The safety of a solar waxer isn't an added feature—it's an inherent result of its simple design. By removing the need for electricity or combustible fuel, it sidesteps the primary hazards that require constant monitoring with other melting methods.

The Principle of Passive Solar Design

A solar waxer operates on the same basic principles as a greenhouse. It is designed to capture solar radiation and convert it into thermal energy, trapping heat to melt beeswax efficiently and safely.

Capturing Solar Energy

The device uses a glass top to allow the sun's rays to enter. This radiation is absorbed by the dark interior surfaces and the wax itself, converting light into heat.

Retaining Heat

Thick, insulated walls are a critical component. They prevent the captured heat from escaping, allowing the internal temperature to build steadily.

Reaching the Melting Point

This simple combination of capturing and retaining heat allows the interior to easily surpass the melting point of beeswax, which is approximately 62°C (144°F).

Why This Design is Fundamentally Safer

The true safety advantage of a solar waxer becomes clear when compared to traditional methods. It doesn't just reduce risk; it eliminates entire categories of hazards.

No Fire or Flame Risk

Many conventional methods involve using a double boiler on a stove with an open flame. This requires constant supervision, as unattended flames are a significant fire hazard. The solar waxer, having no flame, completely removes this danger.

No Electrical Hazards

Electric melters, while avoiding open flames, introduce risks like short circuits, faulty wiring, or overheating electrical components. The solar waxer has no electrical connections or resistances, making such failures impossible.

Durable and Stable Construction

Models built from materials like stainless steel offer excellent durability. This ensures the unit remains stable and contained, preventing spills and structural failures over years of use.

Understanding the Trade-offs

While exceptionally safe, the solar waxer's design comes with practical limitations that you must consider.

Total Dependency on Sunlight

The most significant trade-off is its reliance on the sun. Its effectiveness is dictated by the weather, time of day, and season. It is not an on-demand tool and cannot be used on cloudy days or at night.

Hot Surfaces

While there is no risk of fire, the surfaces of the waxer—especially the glass and metal components—can become extremely hot. Proper care, such as wearing gloves, is necessary when handling the device during and after operation.

Slower Processing Time

Compared to a high-power electric melter or direct heat, the solar method is slower. It melts wax gradually as the sun does its work, which may not be suitable for high-volume, time-sensitive operations.

Making the Right Choice for Your Goal

Your choice of melting method should align with your priorities for safety, speed, and convenience.

- If your primary focus is maximum safety and simplicity: The solar waxer is the unmatched choice, as its passive design eliminates the root causes of fire and electrical accidents.

- If your primary focus is all-weather speed and control: A traditional double boiler or electric melter will be more effective, but you must commit to constant supervision and strict safety protocols to manage the inherent risks.

By relying on the sun, the solar waxer provides the most passive and inherently safe method available for reclaiming and purifying beeswax.

Summary Table:

| Safety Feature | How It Works |

|---|---|

| No Fire Risk | Uses solar energy, eliminating open flames and fuel sources. |

| No Electrical Hazards | No wiring, plugs, or heating elements to short-circuit. |

| Passive Operation | No moving parts; requires no supervision once placed in the sun. |

| Stable Construction | Durable materials like stainless steel prevent spills and failures. |

Ready to upgrade your apiary with the safest wax melting solution?

For commercial apiaries and distributors, efficiency and safety are paramount. HONESTBEE supplies high-quality, durable solar waxers and other essential beekeeping equipment designed for wholesale and commercial use. Let us help you streamline your operations with reliable, risk-free tools.

Contact HONESTBEE today to discuss your wholesale needs and discover our full range of beekeeping supplies.

Visual Guide

Related Products

- Fully Automatic Beeswax Embossing Machine Foundation Mill

- Beeswax Machine Press Embosser Wax Foundation Mold Printer Bee Hive Equipment Making Sheet

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

People Also Ask

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- How does the beeswax flatting and embossing machine flatten the beeswax? Master Precision in Foundation Sheet Production

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency

- What is a fully automatic wax foundation machine and its purpose? Scale Your Beeswax Production with Precision

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction