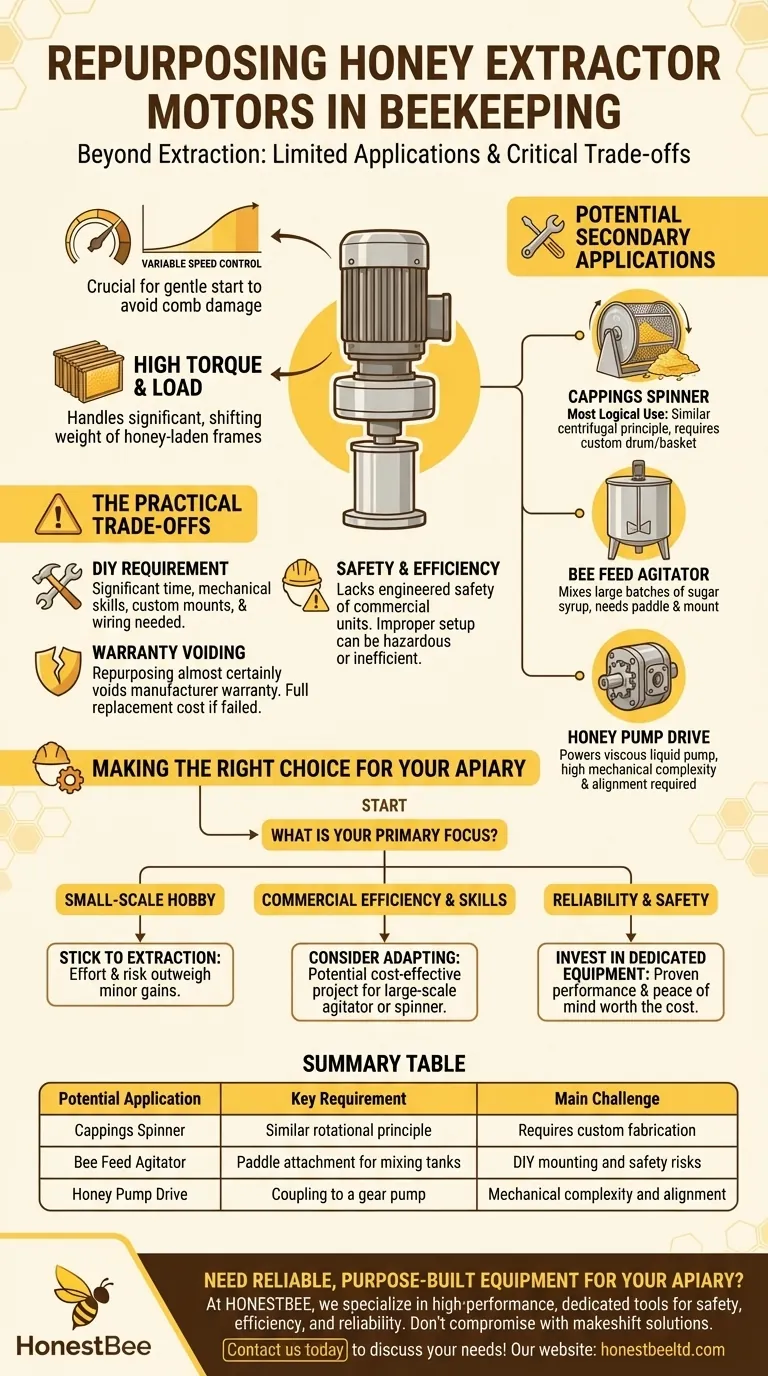

In principle, a honey extractor motor can be adapted for other rotational tasks in a beekeeping operation, but its applications are quite limited. Beyond its primary function, it could potentially be repurposed to power equipment for agitating large batches of sugar syrup for bee feed or to drive a cappings spinner, which operates on a similar principle to an extractor.

The core reality is that a honey extractor motor is a specialized tool designed for a specific task. While repurposing it is technically possible for DIY-inclined beekeepers, its practical use in other areas is limited and often less efficient than using dedicated equipment.

The Motor's Core Design

A honey extractor motor is not just any motor. Its key feature is variable speed control, which is critical for the extraction process.

The Importance of Speed Control

Starting the extraction process at a high speed would shatter delicate, wax-filled combs. Beekeepers must start slowly to extract the honey from one side, flip the frames, and then gradually increase the speed. The motor and its controller are built specifically for this gentle-to-powerful ramp-up.

Torque and Load

These motors are also specified to handle the significant, shifting weight of honey-laden frames. This design for high rotational inertia makes them robust but also over-engineered for many simpler tasks.

Potential Secondary Applications

Thinking of the motor as a "variable-speed rotational power source" opens up a few possibilities, though each requires custom fabrication.

Driving a Cappings Spinner

This is the most logical secondary use. A cappings spinner works just like a honey extractor to centrifugally separate residual honey from wax cappings. Since the process is nearly identical, an extractor motor is perfectly suited for this task if you build a dedicated drum and basket.

Agitating Bee Feed

For beekeepers who mix hundreds of gallons of sugar syrup, manual stirring is exhausting. The motor could be mounted above a large tank and fitted with a paddle attachment to automate the mixing of sugar and water. This ensures the syrup is consistently mixed without manual labor.

Powering a Honey Pump

After extraction, honey must be moved into settling tanks or bottling equipment. A motor could potentially be coupled to a gear pump designed for viscous liquids. However, this requires precise alignment and coupling, making it a mechanically complex project.

The Practical Trade-offs

Before you unbolt your motor, it is crucial to understand the significant downsides and challenges involved in repurposing it.

The DIY Requirement

None of these secondary uses are "plug-and-play." You will need mechanical skills to create stable mounts, fabricate attachments, and potentially wire new controls. The time and material cost of this customization can be significant.

Voiding Your Warranty

Removing the motor from the extractor and using it for an unintended purpose will almost certainly void its manufacturer's warranty. If the motor fails during a custom application, you will be responsible for the full cost of replacement.

Safety and Efficiency

A custom-built syrup mixer or pump lacks the safety features and engineered efficiency of a commercially produced unit. An improperly secured motor can be a serious hazard, and a mismatched setup may perform poorly or strain the motor, leading to premature failure.

Making the Right Choice for Your Apiary

The decision to repurpose your extractor motor depends entirely on the scale of your operation and your technical comfort level.

- If your primary focus is a small-scale hobby: Stick to using the motor for honey extraction. The time, risk, and effort required to adapt it for other tasks far outweigh the minor conveniences you might gain.

- If your primary focus is commercial efficiency and you have mechanical skills: Adapting a motor for a large-scale syrup mixer or a secondary cappings spinner could be a cost-effective project that improves your workflow.

- If your primary focus is reliability and safety: Invest in dedicated equipment for each task. The peace of mind and proven performance of commercial-grade tools are worth the upfront cost.

Ultimately, understanding the motor's specialized design empowers you to decide if its value is best realized in its intended role or through creative, hands-on adaptation.

Summary Table:

| Potential Application | Key Requirement | Main Challenge |

|---|---|---|

| Cappings Spinner | Similar rotational principle | Requires custom fabrication |

| Bee Feed Agitator | Paddle attachment for mixing tanks | DIY mounting and safety risks |

| Honey Pump Drive | Coupling to a gear pump | Mechanical complexity and alignment |

Need reliable, purpose-built equipment for your apiary?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance, dedicated tools that ensure safety, efficiency, and reliability. Don't compromise your workflow with makeshift solutions—let us provide you with the right equipment for every task.

Contact us today to discuss your needs and explore our wholesale-focused product range!

Visual Guide

Related Products

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Professional Multi-Function Stainless Steel Hive Tool

- All-Stainless Steel Pivoting Honey Uncapping Fork for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Commercial Grade Vertical Electric Bee Sweeper for Bee Removal

People Also Ask

- What defensive function do elevated beekeeping platforms provide? Secure Your Apiary from Large Predators

- What are the primary functions of a stainless steel hive tool? Essential Equipment for Professional Beekeeping

- How is a J-hook hive tool designed and what is its primary use? Master Effortless Hive Inspections

- What is the function of a professional stainless steel hive tool in IFB? Optimize Your Colony Strength Assessment

- In what ways do hive-making machines support large-scale commercial bee farms? Scale Efficiently with Precision