At a fundamental level, honey filling machines are engineered to handle a broad spectrum of container volumes. This range spans from small, single-serving honey sticks and sample jars to large retail jars and even bulk foodservice bottles. The specific volume range a single machine can manage is not a fixed industry standard but is dictated by its mechanical design and adjustability.

The critical factor isn't finding a machine that handles every possible volume, but understanding that a machine's filling mechanism—piston, pump, or gravity—is what truly defines its ideal volume range, accuracy, and suitability for your specific type of honey.

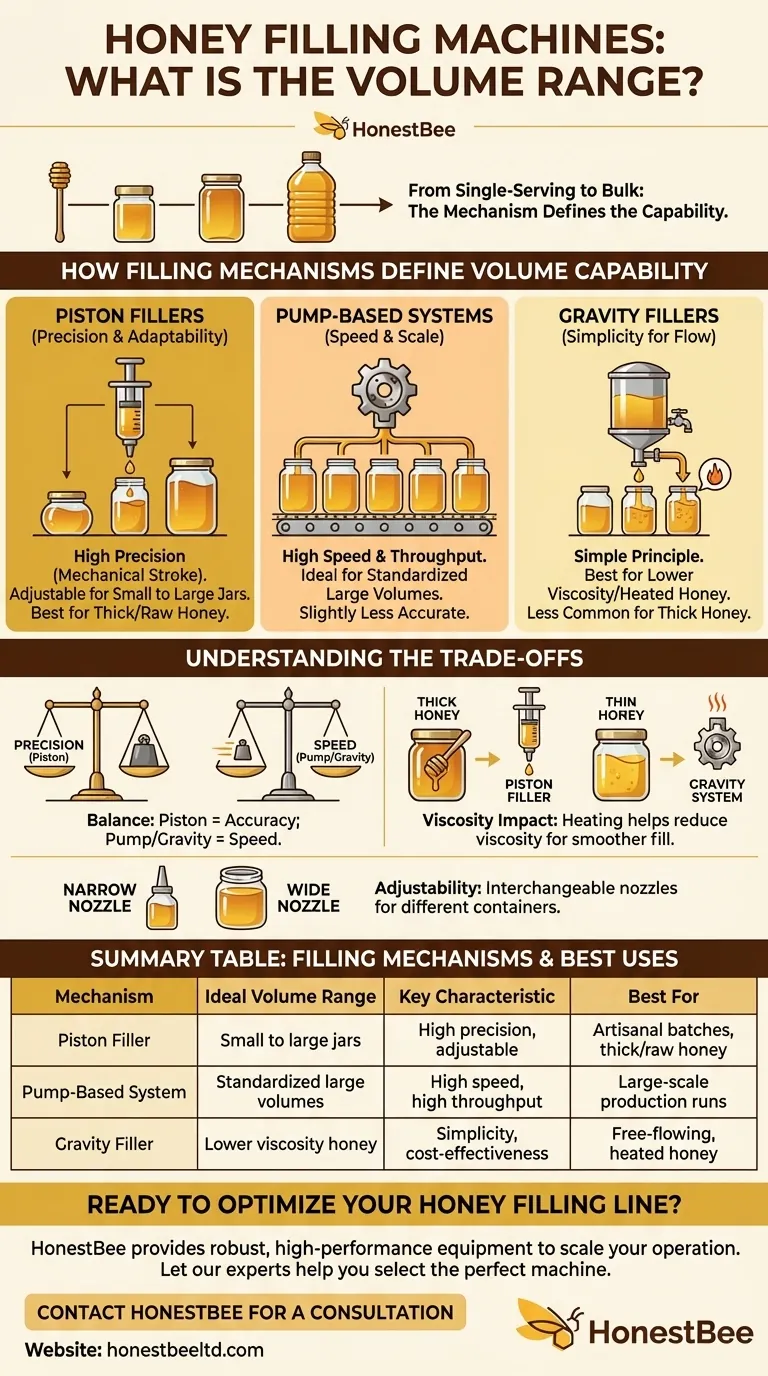

How Filling Mechanisms Define Volume Capability

The "range" of a honey filling machine is a direct consequence of its core technology. Different mechanisms are optimized for different tasks, from precise micro-dosing to rapid bulk filling.

Piston Fillers: The Standard for Precision

A piston filler is the most common and versatile system for honey. It operates like a large syringe, drawing a precise volume of honey into a cylinder and then dispensing it into the container.

The volume is set by adjusting the piston's stroke length. This mechanical precision makes piston fillers exceptionally accurate, which is vital for managing product cost and ensuring consistent packaging for a variety of jar sizes.

Pump-Based Systems: Built for Speed and Scale

For high-volume operations, pump-based systems are the go-to solution. These machines use a pump to regulate a continuous or semi-continuous flow of honey into containers.

While highly efficient for filling thousands of identical jars per hour, their accuracy can be slightly less than a piston filler's. They excel in environments where speed and throughput for a standardized container size are the top priorities.

Gravity Fillers: Simplicity for Lower Viscosity

Gravity fillers work on a simple principle: a tank holding the honey is positioned above the containers, and a valve opens to let gravity do the work.

This method is best suited for less viscous, more free-flowing honey. While less common for thick, raw honey, they can be effective, especially when paired with heating systems to reduce the honey's viscosity.

Understanding the Trade-offs

Choosing a machine involves balancing three critical factors: the speed of the fill, the accuracy of the volume, and the viscosity of your honey.

The Precision vs. Speed Dilemma

Piston fillers offer superior accuracy, minimizing product giveaway and ensuring a consistent customer experience. However, their mechanical cycle (draw and dispense) can make them slower than pump-based systems.

Pump and gravity fillers prioritize speed, making them ideal for large-scale production runs of a single product. The trade-off is a potential for slightly less volumetric precision with each fill.

The Impact of Honey Viscosity

Honey's thickness is a major variable. Thick, crystallized, or raw honey flows poorly and requires the power of a piston filler to be dosed accurately.

Thinner, more liquid honey can be handled by simpler gravity systems. Many machines incorporate gentle heating elements in the hopper or tank to reduce viscosity, ensuring a smooth, air-free fill regardless of the mechanism. This feature is crucial for maintaining flow and achieving accurate fills with thicker honey.

The Role of Adjustability and Nozzles

A machine's volume range is also defined by its physical adjustability. High-quality machines allow for tool-free adjustments to accommodate different container heights and diameters.

Furthermore, interchangeable nozzles are critical. A small nozzle is required for narrow-mouthed bottles or honey sticks, while a larger nozzle is needed to quickly fill wide-mouthed jars without excessive back pressure.

Making the Right Choice for Your Goal

Your decision should be driven by your production scale, product variety, and the nature of your honey.

- If your primary focus is artisanal batches with varied jar sizes: A flexible, single-head piston filler offers the best balance of accuracy and adaptability.

- If your primary focus is high-volume production of a standard jar size: A multi-head pump or rotary filling system will deliver the necessary speed and throughput.

- If your primary focus is handling very thick or raw honey: Prioritize a robust piston filler, and strongly consider a model with an integrated heating system.

Ultimately, selecting the right equipment is about matching the machine's core technology to your specific operational goals.

Summary Table:

| Filling Mechanism | Ideal Volume Range | Key Characteristic | Best For |

|---|---|---|---|

| Piston Filler | Small to large jars | High precision, adjustable | Artisanal batches, thick/raw honey |

| Pump-Based System | Standardized large volumes | High speed, high throughput | Large-scale production runs |

| Gravity Filler | Lower viscosity honey | Simplicity, cost-effectiveness | Free-flowing, heated honey |

Ready to Optimize Your Honey Filling Line?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the robust, high-performance filling equipment you need to scale your operation efficiently. Whether you require the precision of a piston filler for thick honey or the speed of a pump system for high-volume runs, we have the solution.

Let our experts help you select the perfect machine to boost your accuracy and throughput. Contact HONESTBEE today for a personalized consultation on our range of commercial-grade honey filling machines.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What role do automated filling and sealing machines play in large-scale honey export? Scale Your Global Honey Supply

- How does automated filling and packaging equipment affect the shelf life of bee pollen products? Maximize Freshness

- How do automated honey-filling machines contribute to the profitability of beekeeping operations? Maximize Retail Margins

- What core production challenges are addressed by industrial-grade honey-filling machines? Scaling Your Honey Brand.

- What are the benefits of utilizing automatic honey-filling machines? Boost Efficiency and Product Safety

- What are the advantages of using a food-grade syringe for filling honey straws? Precision and Hygiene for Apiaries

- What are the advantages of using automated honey filling equipment? Protect Honey Quality and Physicochemical Integrity

- What is the recommended temperature for honey during the straw-filling process? Optimize Your Honey Flow & Quality