The primary tools used to add intricate details to beeswax sheets are embossing rolls, plates, or stamps. These specialized instruments work by pressing a negative pattern, such as a honeycomb cell base, onto a flat sheet of wax, thereby creating a raised, positive imprint on the surface.

The core principle is not the tool itself, but the process of embossing. The best method—whether using high-speed rolls or simpler plates—depends entirely on your production scale, from commercial manufacturing to small-scale hobbyist work.

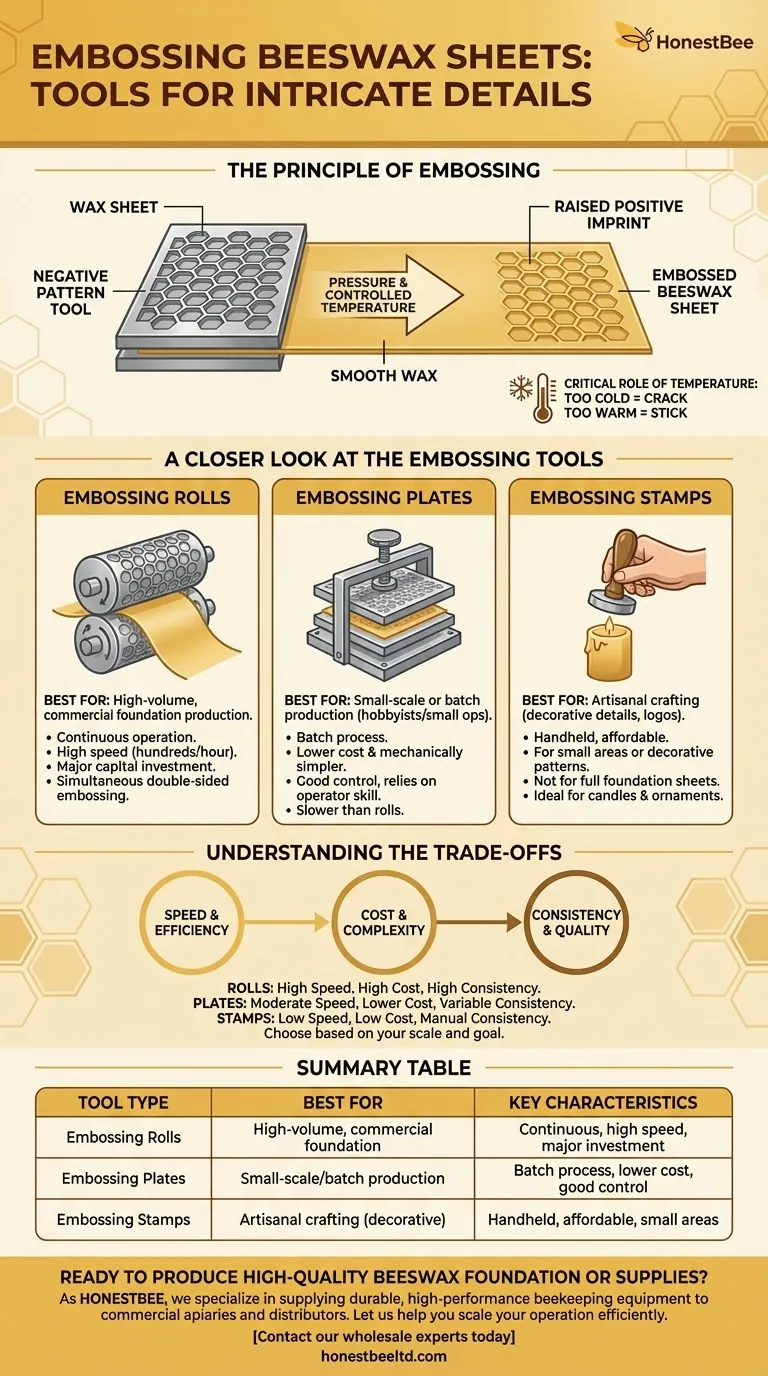

The Principle of Beeswax Embossing

Beeswax embossing is a mechanical process that reshapes a flat wax surface by applying pressure. It's not about cutting or removing material, but displacing it to form a new texture or pattern.

The Embossing Mechanism

The process involves pressing a tool with a precision-engraved pattern onto a smooth sheet of wax. The force applied causes the wax to flow into the engraved cavities of the tool, creating a detailed, raised relief on the wax sheet.

The Critical Role of Temperature

For a clean and accurate impression, the wax must be at the correct temperature. If it's too cold, it will be brittle and crack under pressure. If it's too warm, it will stick to the tool and fail to hold a crisp pattern.

A Closer Look at the Embossing Tools

While the principle is the same, the specific tool used varies significantly based on the intended application and volume of production. The most common use for this process is creating beeswax foundation sheets for beehives.

Embossing Rolls

These are two cylinders, or rolls, engraved with a negative honeycomb cell pattern. A continuous ribbon of smooth wax is fed between the counter-rotating rolls, which emboss the pattern onto both sides simultaneously. This is the method used for high-volume, commercial production.

Embossing Plates

This setup consists of two flat, patterned plates, typically mounted in a press. A single, pre-cut sheet of wax is placed between the plates, and pressure is applied to imprint the pattern. This method is suited for batch production and is common among serious hobbyist beekeepers or smaller-scale operations.

Embossing Stamps

Stamps are smaller, often handheld tools used for adding decorative patterns or specific logos onto wax. They are not used for creating full foundation sheets but are ideal for artisanal crafting, such as decorating candles or wax ornaments.

Understanding the Trade-offs

Choosing between rolls and plates involves a clear trade-off between speed, cost, and scale. There is no single "best" tool; there is only the right tool for a specific goal.

Speed and Efficiency

Embossing rolls are built for speed and continuous operation, capable of producing hundreds of foundation sheets per hour. Plates are a batch process, making them significantly slower.

Cost and Complexity

A machine with embossing rolls is a major capital investment, often costing many thousands of dollars. An embossing plate press is far less expensive and mechanically simpler, making it more accessible.

Consistency and Quality

High-quality rolling mills produce extremely consistent results across thousands of sheets. Plate presses can also produce high-quality sheets, but consistency is more dependent on operator skill in controlling pressure and wax temperature for each batch.

Choosing the Right Method for Your Goal

Your intended outcome directly dictates the right tool for the job. You must first define your scale and purpose before selecting a method.

- If your primary focus is commercial production of beehive foundation: You require a dedicated embossing roll mill for its speed and efficiency.

- If your primary focus is small-scale foundation making for your own apiary: An embossing plate press offers the best balance of cost, control, and quality.

- If your primary focus is adding artistic details to beeswax crafts: Simple, handheld embossing stamps are the most effective and affordable tool.

By matching the tool and technique to your specific goal, you can efficiently transform raw beeswax into a precisely detailed and functional product.

Summary Table:

| Tool Type | Best For | Key Characteristics |

|---|---|---|

| Embossing Rolls | High-volume, commercial foundation production | Continuous operation, high speed, major investment |

| Embossing Plates | Small-scale or batch production (hobbyists/small ops) | Batch process, lower cost, good control |

| Embossing Stamps | Artisanal crafting (decorative details) | Handheld, affordable, for small areas/logos |

Ready to produce high-quality beeswax foundation or supplies? As HONESTBEE, we specialize in supplying durable, high-performance beekeeping equipment and supplies to commercial apiaries and distributors. Let us help you scale your operation efficiently. Contact our wholesale experts today to discuss your needs!

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What are the key components of a wax roller? Build Perfect Foundation for Your Hives

- What are the benefits of making your own beeswax sheets using a mold? Gain Total Control Over Purity and Cost

- What are the operational characteristics of a manual honeycomb embossing machine? Master Precision Foundations

- What is the role of a Wax Printer or Foundation Mold in improving honeybee hive construction efficiency? Save Bee Energy

- What is the function of a manual tablet press machine in beekeeping? Create Pure Beeswax Foundation for Your Hives

- What specific equipment is required for making beeswax foundation? Essential Tools for High-Quality Production

- Why are wax foundation machines and casting molds necessary? Build Stronger Hives and Maximize Honey Yields

- How should a newly poured beeswax sheet be cooled and removed? Master the Warm-But-Firm Release Technique