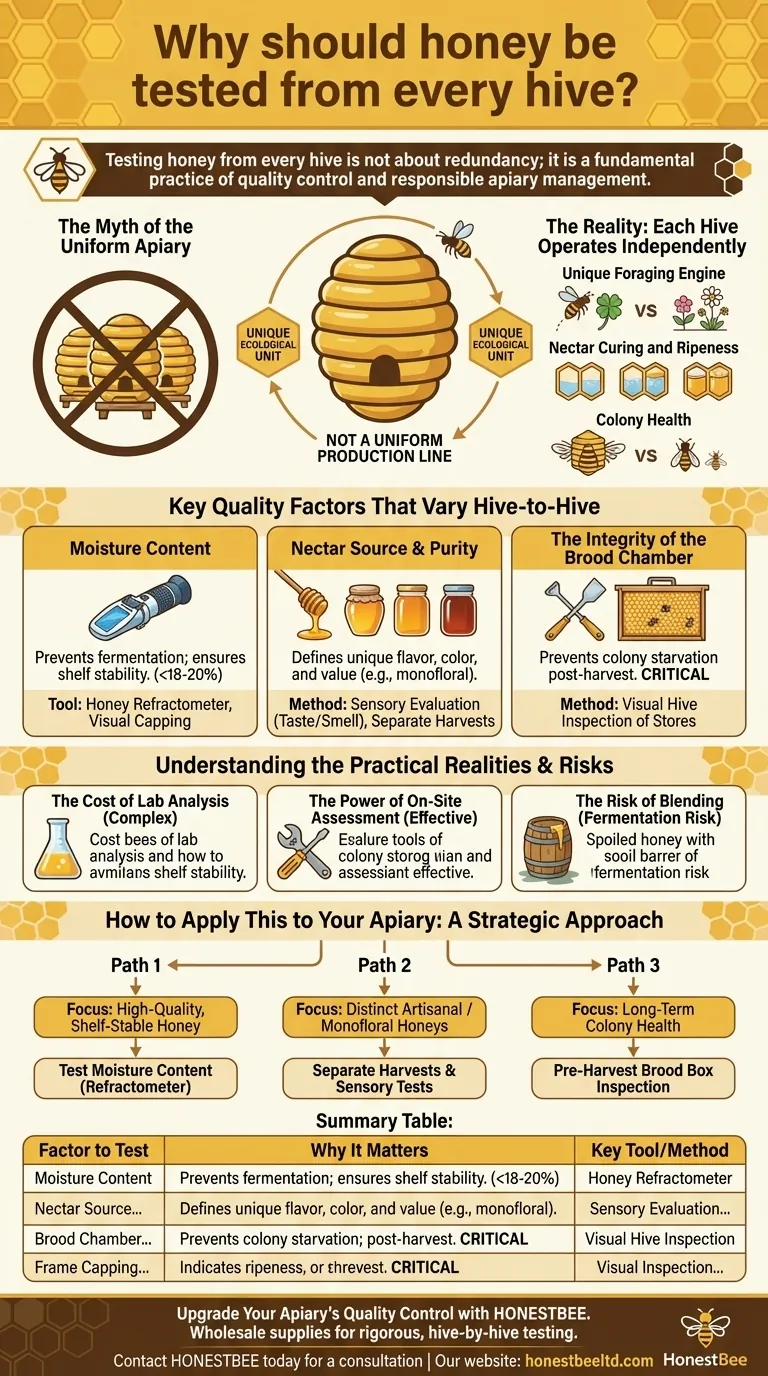

Testing honey from every hive is not about redundancy; it is a fundamental practice of quality control and responsible apiary management. Honey's composition can vary dramatically from one colony to the next—and even between different frames in the same hive—based on the colony's health, foraging patterns, and efficiency in curing nectar. This variability directly impacts the honey's stability, flavor, and the long-term health of the bees themselves.

The core principle is that each hive is a distinct ecological unit, not a uniform production line. Testing from every hive shifts the focus from assuming consistency to actively managing the unique characteristics of each colony's output and ensuring its long-term survival.

The Myth of the Uniform Apiary

Many beekeepers view an apiary as a single entity, but the reality is far more complex. Each hive operates independently, leading to significant differences in the final product.

Each Hive is a Unique Foraging Engine

Even in the same yard, colonies develop distinct foraging preferences. One hive's workforce may focus on a field of clover, while its neighbor discovers a patch of wildflowers a short distance away. Stronger, more populous colonies can also cover a wider territory, accessing different nectar sources than weaker hives.

Nectar Curing and Ripeness

Bees transform nectar into honey by reducing its water content and adding enzymes. This "curing" process is complete when the honey is "ripe," at which point the bees cap the cell with wax. The speed and effectiveness of this process depend entirely on the colony's population and internal temperature regulation.

Colony Health is a Key Variable

A robust, healthy colony will not only gather more nectar but will also be more efficient at curing and capping it. A weaker hive may struggle, leaving honey with higher moisture content or failing to cap it at all.

Key Quality Factors That Vary Hive-to-Hive

"Testing" is not exclusively about laboratory analysis. For a beekeeper, it includes a series of critical on-site assessments that determine the quality of the honey and the health of the hive.

Moisture Content

This is the single most important factor for shelf stability. Honey with a moisture content above 18-20% is at high risk of fermenting. Beekeepers test this by observing the comb—fully capped honey is ripe and has low moisture—and by using a tool called a honey refractometer. A single frame of uncapped, high-moisture honey can spoil an entire batch if blended unknowingly.

Nectar Source and Purity

The nectar source dictates the honey's color, flavor, and aroma. By keeping harvests from different hives separate, at least initially, a beekeeper can identify unique floral varieties. This sensory evaluation is a form of testing that is crucial for producing distinct artisanal or monofloral honey.

The Integrity of the Brood Chamber

A critical pre-harvest "test" involves inspecting the entire hive, not just the honey supers. The brood boxes must contain sufficient honey stores for the colony to survive. Harvesting from the supers without confirming the colony's own food reserves can lead to starvation.

Understanding the Practical Realities

While testing every batch is ideal, the method of testing must align with your goals and resources.

The Cost of Lab Analysis

Sending samples from every single hive for comprehensive laboratory analysis is not practical or necessary for most beekeepers. This level of scrutiny is typically reserved for large commercial operations or those seeking specific certifications.

The Power of On-Site Assessment

The most effective strategy combines visual inspection with simple tools. Look for fully capped frames, taste the honey for unique flavor profiles, and use a refractometer to get a definitive moisture reading. These practices provide the critical data needed for quality control.

The Risk of Blending Without Knowledge

The primary alternative to individual testing is to combine all honey from the apiary into one large batch. This approach prioritizes volume over quality and carries a significant risk. One hive's high-moisture honey can trigger fermentation across the entire harvest, ruining months of work.

How to Apply This to Your Apiary

A strategic approach to testing allows you to protect your bees and your product. Your primary goal should determine your method.

- If your primary focus is producing high-quality, shelf-stable honey: Prioritize testing the moisture content from each super with a refractometer before you begin extraction.

- If your primary focus is creating distinct artisanal or monofloral honeys: Keep harvests from different hives and locations separate until you can perform sensory tests (taste, smell, color) to identify unique batches.

- If your primary focus is the long-term health of your bees: Your most critical "test" is the pre-harvest inspection of brood box stores to ensure you leave more than enough honey for the colony's survival.

This hive-centric approach transforms honey harvesting from a simple collection into a strategic act of quality control and responsible stewardship.

Summary Table:

| Factor to Test | Why It Matters | Key Tool/Method |

|---|---|---|

| Moisture Content | Prevents fermentation; ensures shelf stability. | Honey Refractometer |

| Nectar Source & Purity | Defines unique flavor, color, and value (e.g., monofloral). | Sensory Evaluation (Taste/Smell) |

| Brood Chamber Honey Stores | Prevents colony starvation post-harvest. | Visual Hive Inspection |

| Frame Capping Completeness | Indicates ripeness and proper curing by the bees. | Visual Inspection of Honey Supers |

Upgrade Your Apiary's Quality Control with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, consistent quality is paramount to your success and reputation. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and equipment—like precision honey refractometers and essential hive tools—you need to implement a rigorous, hive-by-hive testing protocol.

Ensure every batch of honey meets the highest standards of stability and purity while safeguarding the long-term health of your colonies. Let's discuss your operational needs and how our products can help.

Contact HONESTBEE today for a consultation

Visual Guide

Related Products

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What operational benefits do motorized honey extractors provide? Scale Your Harvest Efficiency

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- What are the primary advantages of utilizing a manual honey extractor? Cost-Effective & Gentle Harvesting

- What are the disadvantages of a manual honey extractor? Overcome Efficiency Bottlenecks in Your Apiary

- How do mechanical aspirators improve efficiency in stingless bee honey harvesting? Boost Your Apiary's Productivity