It’s 3 AM. You’re halfway to the almond orchards, and you hear a sickening shift-and-crunch from the flatbed. That’s not just the sound of splintering wood; it’s the sound of a failed strap, a toppled pallet, and a significant portion of your contract revenue vanishing into the dark. For any commercial beekeeper, it’s a scenario that represents one of the biggest, most stressful risks in the business.

Moving bees is a fundamental part of the job, but it’s often treated as a brute-force logistical task. The reality is that your approach to hive transport is a core business process with a direct impact on your profitability, scalability, and reputation.

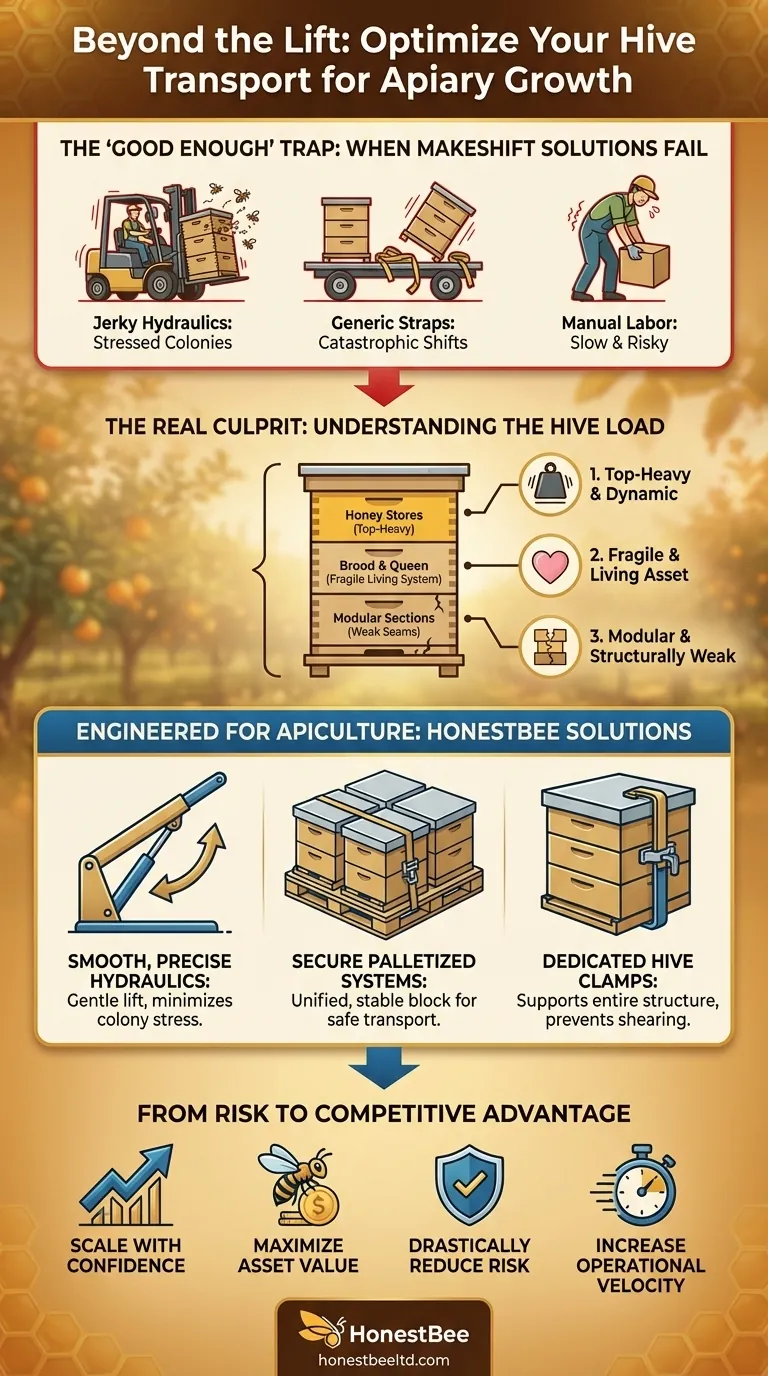

The 'Good Enough' Trap: When Makeshift Solutions Fail

Every commercial operator understands that moving hundreds of hives requires more than a strong back. But many fall into the "good enough" trap, relying on equipment that wasn't designed for the unique challenges of the job.

This often looks like:

- General-purpose forklifts whose jerky hydraulics shake colonies, stress queens, and can lead to lower pollination vigor.

- Standard flatbeds with generic straps that can't properly secure a modular, top-heavy stack of hive bodies, creating the perfect conditions for a catastrophic shift in transit.

- Over-reliance on manual labor for adjustments and positioning, which slows down the entire operation and makes back injuries a constant, expensive threat.

These compromises aren't just inefficient; they have severe business consequences. A single dropped pallet can mean thousands of dollars in lost bees and honey production. A stressed colony is an underperforming one, directly impacting your pollination results. And an operation slowed by inadequate equipment can't scale to take on larger, more lucrative contracts. You are limited not by your beekeeping skill, but by your logistical bottleneck.

The Real Culprit: A Beehive Isn't Just a Heavy Box

Why do these common-sense, "good enough" solutions so often fail? Because they ignore the fundamental physics of what a beehive actually is. The problem isn't the weight alone; it’s the nature of the load.

A beehive presents three distinct engineering challenges that standard equipment is not built to handle:

1. It’s a Top-Heavy, Dynamic Load

A full hive, with its concentration of honey at the top, is inherently unstable. Unlike a static pallet of bricks, it’s a living system. A sudden stop or a bumpy road can cause internal shifts that magnify its instability. A generic lift isn't designed for this delicate balancing act.

2. It’s a Fragile, Living Asset

The goal isn't just to move a box from point A to point B. The goal is to move a living, breathing superorganism without causing it undue stress. Sharp jolts can dislodge frames, kill brood, and even lead to the loss of a queen. Overheating is another critical risk if hives are packed too tightly without proper handling considerations.

3. It’s a Modular, Structurally Weak Column

A beehive is a stack of individual boxes. Its weakest points are the seams between each super. A simple strap over the top might hold it down, but it does little to prevent the boxes from shearing or sliding apart during transit. This is the primary cause of catastrophic load failures.

Makeshift solutions fail because they treat the symptom (weight) while ignoring the root causes (instability, fragility, and modularity).

Engineered for Apiculture: The Right Tool for a Unique Job

To truly solve this problem, you don't need a stronger forklift; you need smarter equipment engineered from the ground up with the beehive in mind. You need a system that addresses the core challenges of instability, fragility, and modular construction.

This is where purpose-built hive transport equipment becomes a strategic investment, not just a cost.

At HONESTBEE, our solutions are designed to directly counter these root problems:

- Smooth, Precise Hydraulics: Our vehicle-mounted loaders are engineered for a gentle, controlled lift, minimizing the jarring motions that stress colonies and threaten stability.

- Secure Palletized Systems: We provide systems that secure hives to a pallet, transforming multiple unstable stacks into a single, unified block that is far easier to handle and transport safely.

- Dedicated Hive Clamps & Lifts: Our equipment is built to grip and support the entire hive structure, preventing the dangerous shearing and separation that plagues generic strapping methods.

This isn’t about simply lifting more weight. It's about controlling the load, protecting the asset, and creating a repeatable, safe, and efficient process for your entire operation.

From Logistical Headache to Competitive Advantage

When you solve the transport problem correctly, something powerful happens. It ceases to be a major source of risk and becomes a source of competitive strength.

With a professional hive transport system in place, you can now:

- Scale with Confidence: Take on those larger pollination contracts knowing you have the logistical capacity to deploy hundreds of hives safely and on schedule.

- Maximize Asset Value: Deliver healthier, less-stressed colonies to the field, leading to better pollination results and stronger hives for honey production.

- Drastically Reduce Risk: Protect your bottom line by minimizing the risk of catastrophic load shifts, colony loss, and employee injury.

- Increase Operational Velocity: Load and unload faster, enabling you to service more clients and deploy your colonies with greater agility.

Your operation is unique. Your challenges with terrain, scale, and speed are specific to you. It's time to move beyond generic solutions that put a ceiling on your growth.

Let's discuss an equipment strategy that secures your assets, protects your team, and unlocks your apiary's true potential. Contact Our Experts to get a quote and find the right solution for your commercial operation.

Visual Guide

Related Products

- Professional Grade Foldable Beehive Handles

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Premium Comfort Grip Spring-Loaded Hive Handles

- Ergonomic Two Person Foldable Hive Lifter

- Versatile Ratchet Hive Strap with S-Hooks for Secure Fastening

Related Articles

- How to Master Bee Brush Techniques for Stress-Free Hive Inspections

- More Than Steel: Choosing the Right Hive Tool for Apiary Efficiency

- How to Use a Bee Brush Correctly: Protecting Bees While Boosting Apiary Productivity

- Guide to Starting a Bee Hive in 7 Steps

- How Bee Box-Making Machines Transform Beekeeping Efficiency and Sustainability