Product Design and Functionality

Core Operations

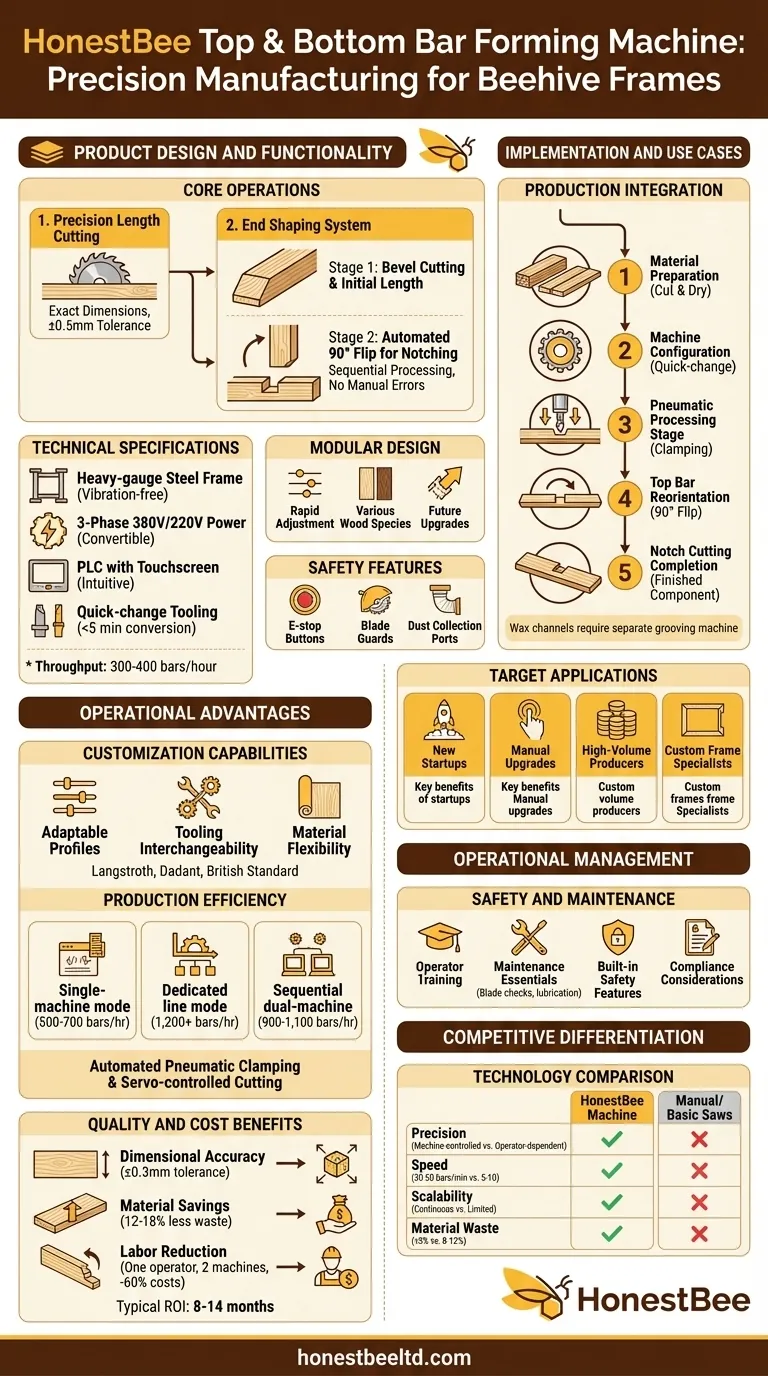

The HonestBee Top & Bottom Bar Forming Machine revolutionizes beehive frame manufacturing by transforming raw wood strips into precision components through two key operations:

-

Precision Length Cutting

- Achieves exact dimensional requirements for both top and bottom bars

- Maintains ±0.5mm tolerance for perfect frame assembly

-

End Shaping System

- Creates beveled edges for smooth frame insertion

- Produces interlocking notches through patented dual-stage processing:

Stage 1: Initial length and bevel cutting

Stage 2: Automated 90° flip for notch creation

This sequential processing enables complete top bar formation in a single machine cycle, eliminating manual repositioning errors.

Technical Specifications

Built for industrial beekeeping operations, the machine features:

| Feature | Specification | Benefit |

|---|---|---|

| Construction | Heavy-gauge steel frame | Vibration-free operation at high speeds |

| Power Options | 3-phase 380V/220V convertible | Global workshop compatibility |

| Control System | PLC with touchscreen interface | Intuitive operation with preset programs |

| Tooling System | Quick-change blade mounts | <5 minute conversion between top/bottom bar production |

| Throughput | 300-400 bars/hour (depending on complexity) | Matches mid-volume production needs |

The machine's modular design allows for:

- Rapid adjustment of cutting parameters

- Accommodation of various wood species and densities

- Future upgrades for additional frame standards

Safety features include emergency stop buttons, blade guards, and integrated dust collection ports for compliant workshop environments.

Operational Advantages

Customization Capabilities

The HonestBee forming machine is engineered to accommodate all major beehive frame standards, including Langstroth, Dadant, and British Standard designs. Its modular tooling system allows for bespoke modifications, ensuring compatibility with both conventional and proprietary frame specifications.

Key customization features include:

- Adaptable cutting profiles – Supports unique bar shapes, tapered ends, and specialty notches.

- Tooling interchangeability – Quick-change components enable seamless transitions between top and bottom bar production.

- Material flexibility – Processes various wood types (pine, cedar, etc.) without compromising precision.

This adaptability makes the machine ideal for manufacturers serving diverse apiculture markets or developing proprietary frame systems.

Production Efficiency

The machine offers three workflow configurations to match different production scales:

| Configuration | Throughput Capacity | Best For |

|---|---|---|

| Single-machine mode | 500–700 bars/hour | Small workshops or mixed bar production |

| Dedicated line mode | 1,200+ bars/hour | High-volume top/bottom bar specialization |

| Sequential dual-machine | 900–1,100 bars/hour | Optimized top bar production (bevel + notch stages) |

Automated pneumatic clamping and servo-controlled cutting minimize manual intervention, while the 90° flip mechanism for top bar notching ensures uninterrupted processing.

Quality and Cost Benefits

Precision engineering delivers measurable advantages:

- Dimensional accuracy – ±0.3mm tolerance guarantees frame assembly consistency, critical for hive stacking.

- Material savings – Automated length optimization reduces wood waste by 12–18% versus manual methods.

- Labor reduction – One operator can manage two machines, cutting per-unit labor costs by up to 60%.

These benefits compound in high-volume production, with ROI typically achieved within 8–14 months for mid-sized operations.

Implementation and Use Cases

Production Integration

The HonestBee Top & Bottom Bar Forming Machine follows a streamlined five-step workflow designed for efficient production:

-

Material Preparation

- Raw wood strips are cut to approximate lengths before processing

- Proper drying and quality checks ensure optimal machining results

-

Machine Configuration

- Quick-change tooling adapts between top/bottom bar profiles

- Cutting parameters adjusted via intuitive control panel

-

Pneumatic Processing Stage

- Automated clamping secures workpieces during cutting

- Simultaneous length cutting and end shaping operations

-

Top Bar Reorientation

- Special 90° flip mechanism for interlocking notch creation

- Second-stage processing without manual repositioning

-

Notch Cutting Completion

- Precision cutting of interlocking features

- Finished components automatically ejected

Note: Foundation wax channels require separate processing with a grooving machine, as this specialized operation falls outside the machine's core functionality.

Target Applications

This system delivers maximum value for four distinct manufacturing scenarios:

| Application Type | Key Benefits |

|---|---|

| New Manufacturing Startups | Eliminates manual skill dependencies while ensuring production-ready quality from day one |

| Manual Operation Upgrades | 10-15x throughput increase compared to hand tool methods with superior consistency |

| High-Volume Producers | Enables 24/7 operation with minimal supervision through automated processing |

| Custom Frame Specialists | Accommodates proprietary designs through adjustable cutting profiles and tooling |

The machine's dual compatibility with both top and bottom bars makes it particularly valuable for operations producing complete frame sets, while its modular design allows integration into existing production lines or standalone workshop setups.

Operational Management

Safety and Maintenance

The HonestBee Top & Bottom Bar Forming Machine prioritizes operator safety and equipment longevity through thoughtful engineering and maintenance protocols.

Operator Training Requirements:

- Comprehensive instruction on machine controls and emergency stops

- Proper handling techniques for wood stock feeding

- Safety procedures for blade changes and adjustments

Maintenance Essentials:

- Weekly blade inspections for sharpness and alignment

- Monthly lubrication of moving parts

- Quarterly checks of pneumatic systems and electrical components

Built-in Safety Features:

- Interlocked safety guards preventing access during operation

- Emergency stop buttons at multiple access points

- Dust extraction ports maintaining clean workshop air quality

Compliance Considerations:

- Meets workshop safety standards for woodworking machinery

- Designed for integration with standard dust collection systems

- Electrical systems configured for regional voltage requirements

Proper maintenance ensures consistent cutting precision while minimizing downtime. The machine's design facilitates easy access to critical components for servicing without compromising structural integrity.

Operators should maintain a log documenting maintenance activities, blade replacements, and any operational anomalies. This practice supports both equipment reliability and workplace safety compliance.

Competitive Differentiation

Technology Comparison

The HonestBee Top & Bottom Bar Forming Machine establishes clear technological advantages over traditional manual saws and basic cutting equipment through measurable performance improvements:

| Performance Metric | HonestBee Machine | Manual/Basic Saws |

|---|---|---|

| Precision | Machine-controlled (±0.5mm tolerance) | Operator-dependent (variable results) |

| Speed | Automated cycles (30–50 bars/minute) | Labor-intensive (5–10 bars/minute) |

| Scalability | Continuous production with minimal supervision | Limited by human labor capacity |

| Material Waste | Optimized cutting paths (<3% waste) | Higher kerf loss (8–12% waste) |

Key differentiators include:

- Consistency: Eliminates human error in bevel angles and notch dimensions, critical for hive assembly.

- Throughput: Processes both top and bottom bars in a single setup, reducing changeover downtime.

- Adaptability: Adjustable tooling accommodates diverse frame standards without requiring separate machines.

For operations transitioning from manual methods, the machine’s automation directly translates to higher yield rates and lower per-unit production costs.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

Related Articles

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization