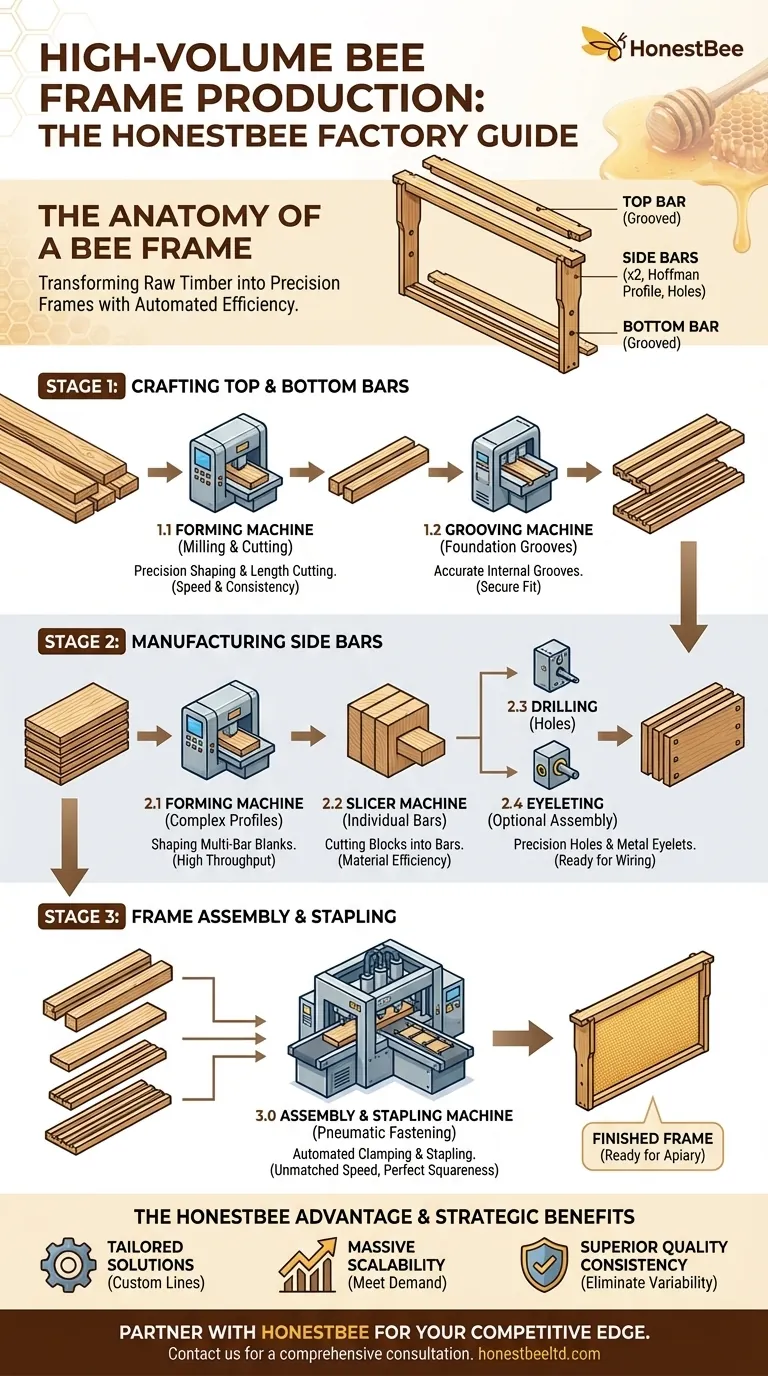

For large-scale commercial beekeeping equipment manufacturers and distributors, producing bee frames isn't just a task; it's a high-volume, precision-driven industrial process. Meeting the constant demand for high-quality, consistently dimensioned Langstroth, Dadant, British Standard, and other specialized hive frames requires more than just skilled labor – it demands a robust, efficient, and scalable production line. Manual methods simply cannot keep pace, and piecemeal mechanization often creates bottlenecks.

This article delves into the essential steps and specialized bee frame machine solutions required to establish a professional bee frame factory, transforming raw timber into thousands of perfectly crafted frames ready for apiaries worldwide. HONESTBEE is your expert partner in designing and implementing these comprehensive production lines, tailored to your exact specifications.

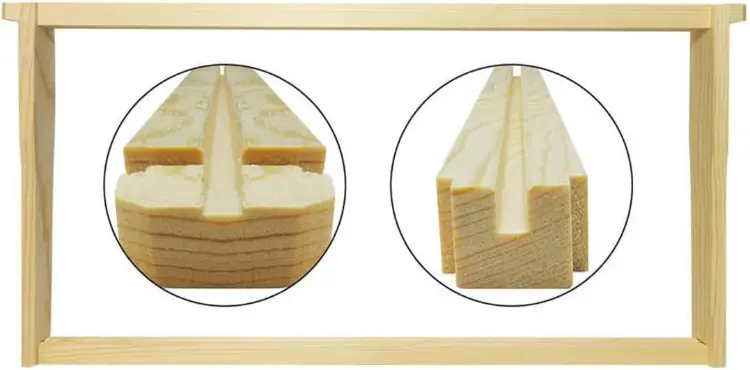

The Anatomy of a Bee Frame: Understanding the Components

Before diving into the machinery, let's quickly review the key components of a standard bee frame that our factory line will produce:

- Top Bar: The uppermost piece of the frame, often featuring specific end profiles for hanging in the hive body and a groove for holding the beeswax foundation.

- Bottom Bar: The lowermost piece, typically grooved to secure the foundation and featuring end profiles for joining with the side bars.

- Side Bars (x2): The vertical pieces that determine the frame's depth. They often include features like Hoffman self-spacing profiles, end grooves for assembly, and holes for wiring.

The Factory Blueprint: A Step-by-Step Production Line with HONESTBEE Bee Frame Machines

A high-efficiency bee frame factory organizes production into distinct stages, each optimized with specialized machinery for maximum output and consistent quality. HONESTBEE offers a complete suite of bee frame machines to power each step:

Stage 1: Crafting Top Bars & Bottom Bars – Precision Forming & Grooving

The foundation of a sturdy frame starts with perfectly dimensioned top and bottom bars.

-

Step 1.1: Forming Top & Bottom Bars

- Machine: HONESTBEE Top Bar & Bottom Bar Forming Machine

![bee frame machine]()

- Function: This powerful bee frame machine takes pre-dimensioned timber planks and, in a continuous automated process, mills them to the precise width, thickness, and end profiles (e.g., L-tenons for top bars, straight tenons for bottom bars) required. It also cuts the formed timber to the exact length needed for your specific frame type (Langstroth, Dadant, etc.).

![bee frame machine]()

- How it Works: Timber planks are fed into the machine via rollers. A series of high-speed, industrial-grade cutter heads shape all four sides and the end profiles simultaneously. An integrated saw then performs the final length cut.

- Advantages over other methods:

- Speed & Volume: Dramatically outperforms manual shaping or using separate planers, jointers, and saws.

- Consistency: Every bar is dimensionally identical, crucial for automated assembly and perfect frame fit.

- Reduced Labor: Automates multiple shaping and cutting steps.

- Value to Your Factory: Massively increases throughput of top/bottom bar blanks, ensuring a steady supply for the next stages and significantly reducing per-unit labor costs.

- Machine: HONESTBEE Top Bar & Bottom Bar Forming Machine

-

Step 1.2: Grooving Top & Bottom Bars

- Machine: HONESTBEE Grooving Machine

![bee frame machine]()

- Function: This specialized bee frame machine cuts the critical internal grooves into the top bars (for foundation insertion) and bottom bars (for foundation security).

![bee frame machine]()

- How it Works: The pre-formed top or bottom bars are fed through the machine, where a precisely positioned high-speed cutter mills the groove to the exact depth and width required.

- Advantages over other methods:

- Precision Grooves: Ensures foundation fits snugly and securely. Manual routing is far less consistent.

- Speed: Designed for high-volume grooving.

- Value to Your Factory: Guarantees that all frames will hold foundation correctly, a key quality aspect for beekeepers.

- Machine: HONESTBEE Grooving Machine

Stage 2: Manufacturing Side Bars – Shaping, Slicing, Drilling & Eyeleting

Side bars, often with more complex profiles like Hoffman spacing, require dedicated processing.

-

Step 2.1: Forming Side Bars

- Machine: HONESTBEE Side Bar Forming Machine.

![bee frame machine]()

- Function: This robust bee frame machine takes stacked timber planks and shapes them into a continuous "side bar blank." This blank contains the profiles for multiple side bars (e.g., Hoffman shoulders, end grooves) and is cut to the precise length of the final side bar.

![bee frame machine]()

- How it Works: Stacked planks are fed automatically. Multiple cutting heads shape the top, bottom, and edge profiles required for the side bars.

- Advantages over other methods:

- Complex Profile Capability: Efficiently creates intricate Hoffman self-spacing profiles which are very time-consuming to do manually or with general tools.

- High Throughput: Processes large volumes of timber into accurately shaped side bar blanks.

- Value to Your Factory: The cornerstone for producing high-quality, consistently shaped side bars, especially critical for self-spacing frame designs.

- Machine: HONESTBEE Side Bar Forming Machine.

-

Step 2.2: Slicing Side Bar Blocks

- Machine: HONESTBEE Side Bar Slicer

![bee frame machine]()

- Function: The Side Bar Forming Machine produced a multi-bar "block," this specialized bee frame machine accurately slices that block into individual, finished side bars.

![bee frame mchine]()

- How it Works: The formed side bar block is fed through a series of precisely spaced saw blades, which cut it into individual side bars of the correct thickness.

- Advantages over other methods:

- Material Efficiency: Maximizes yield from the initial timber block.

- Speed & Accuracy: Far faster and more precise than trying to rip individual side bars from wider planks after initial shaping.

- Value to Your Factory: Optimizes material usage and rapidly converts formed blocks into ready-to-use side bars, feeding the assembly line efficiently.

- Machine: HONESTBEE Side Bar Slicer

-

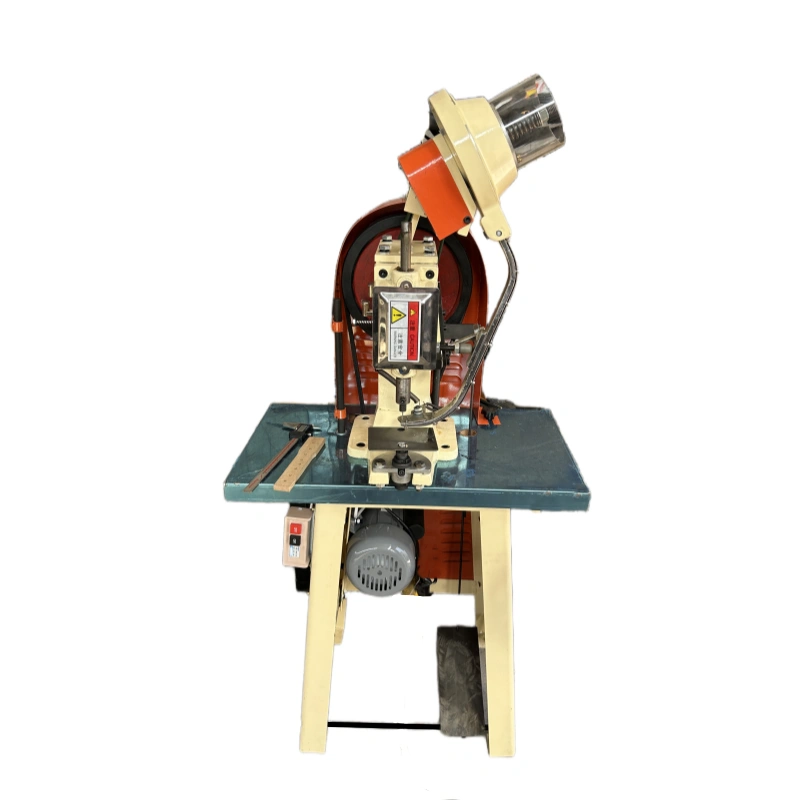

Step 2.3: Drilling Holes in Side Bars (Optional but common)

- Machine: HONESTBEE Hole Puncher Machine / Side Bar Drilling Machine

![bee frame machine]()

- Function: This compact and efficient bee frame machine is designed to drill multiple, precisely spaced holes along the length of the individual side bars.

![bee frame machine]()

- How it Works: Side bars are placed into a jig with an adjustable ruler/guide. The operator then advances the side bar, and a high-speed drill bit creates the holes at pre-set intervals.

- Advantages over other methods:

- Accuracy & Repeatability: Ensures holes are perfectly aligned for easy wiring and eyelet insertion. Manual drilling is prone to errors.

- Speed for a Dedicated Task: Much faster than using a standard drill press for this repetitive task.

- Value to Your Factory: Prepares side bars for wiring, a crucial step for frames intended to hold foundation with wire support.

- Machine: HONESTBEE Hole Puncher Machine / Side Bar Drilling Machine

-

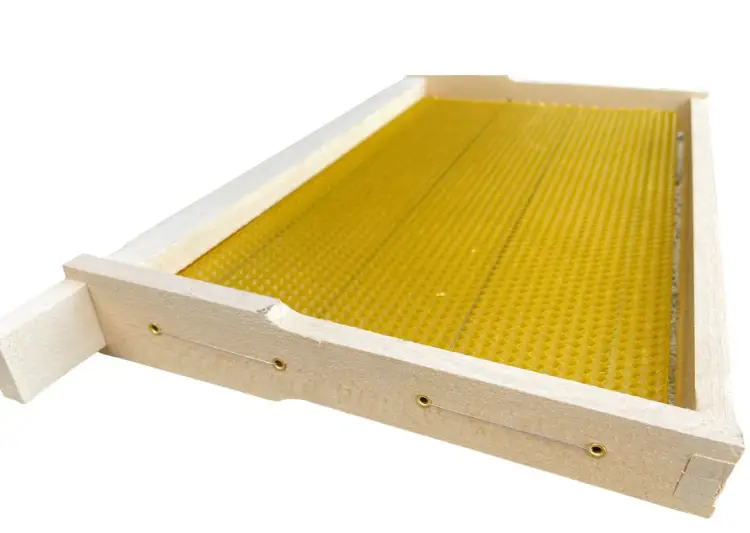

Step 2.4: Assembling Eyelets (Optional)

- Machine: HONESTBEE Eyelets Assembly Machine

![bee frame machine]()

- Function: If your frames require metal eyelets in the drilled holes (to prevent wire from cutting into the wood), this specialized bee frame machine automates their insertion.

![bee frame machine]()

- How it Works: Side bars with pre-drilled holes are fed into the machine. Eyelets are dispensed from a hopper and pressed securely into each hole.

- Advantages over other methods:

- Speed & Efficiency: Far faster than manually inserting and setting eyelets.

- Consistency: Ensures eyelets are properly seated every time.

- Value to Your Factory: Adds a professional finish and enhances the durability of wired frames, reducing labor for a tedious task.

- Machine: HONESTBEE Eyelets Assembly Machine

Stage 3: Frame Assembly & Stapling (If offering assembled frames)

For factories providing ready-to-use frames, this final stage is crucial.

- Machine: HONESTBEE Frame Assembly and Stapling Machine

![bee frame machine]()

- Function: This powerful pneumatic bee frame machine takes all the perfectly machined top bars, bottom bars, and side bars, clamps them into a perfectly square jig, and simultaneously drives multiple staples to securely assemble the entire frame in seconds.

![bee frame machine]()

- How it Works: The operator places the components into the custom jig. Pneumatic clamps secure the parts, and then multiple pneumatic staple guns fire, creating strong, consistent joints.

- Advantages over other methods:

- Unmatched Assembly Speed: Assembles frames at a rate of approximately 360 per hour.

- Perfectly Square & Strong Frames: Eliminates human error in alignment and fastening power.

- Reduced Labor: One operator can achieve massive output.

- Value to Your Factory: Allows you to offer fully assembled, high-quality frames at a competitive price, meeting the needs of beekeepers who prefer ready-to-use equipment. Massively increases your finished goods output.

The HONESTBEE Advantage: Your Partner for Comprehensive Bee Frame Production Lines

Choosing HONESTBEE for your factory's bee frame machine needs means investing in more than just equipment; you're investing in a strategic partnership:

- Complete, Tailored Solutions: We don't just sell individual machines. We specialize in designing and delivering fully customized, integrated bee frame production lines to meet your specific output requirements, frame types (Langstroth, Dadant, British Standard, National, Smith, and custom designs), and factory layout.

- Precision Engineering & Durability: Our machines are built for industrial use, ensuring longevity, reliability, and consistent performance.

- Efficiency at Every Stage: Each HONESTBEE bee frame machine is optimized for its specific task, minimizing waste, reducing labor, and maximizing throughput.

- Global Compatibility: We provide voltage customization to ensure seamless integration into your facility, wherever it may be.

- Expert Support & Spare Parts: We understand that uptime is critical. HONESTBEE provides ongoing support and a reliable supply of spare parts to keep your production line running smoothly.

Why a HONESTBEE Automated Production Line is a Strategic Imperative

For a large-scale bee frame production enterprise, a HONESTBEE automated line offers transformative benefits:

- Massive Scalability: Easily scale your production up or down to meet fluctuating market demands without a proportional increase in labor.

- Superior Cost Control: Reduced labor, optimized material use (with precision cutting), and higher throughput lead to a significantly lower cost per frame.

- Unbeatable Quality Consistency: Automated processes eliminate human variability, ensuring every frame meets your highest quality standards. This builds brand reputation and customer loyalty.

- Competitive Edge: The ability to produce high volumes of top-quality frames at a competitive price point positions you as a leader in the market.

- Focus on Growth: By automating the core manufacturing processes, you can free up resources to focus on sales, marketing, distribution, and new product development.

Is Your Factory Ready to Dominate the Bee Frame Market? Partner with HONESTBEE.

The future of efficient, high-quality bee frame production is here. Stop grappling with the limitations of outdated methods and unlock the immense potential of a fully integrated, customized production line powered by HONESTBEE bee frame machines. From individual component manufacturing to complete frame assembly, we provide the expertise and the technology to elevate your factory to new heights of productivity and profitability.

Contact HONESTBEE today for a comprehensive consultation on your bee frame factory needs. Let our experts design a tailored production line solution – for Langstroth, Dadant, British Standard, or any specialized frame – that will become the engine of your success!

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

Related Articles

- Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- How the Beehive Frame Machine Transforms Apiary Equipment Production