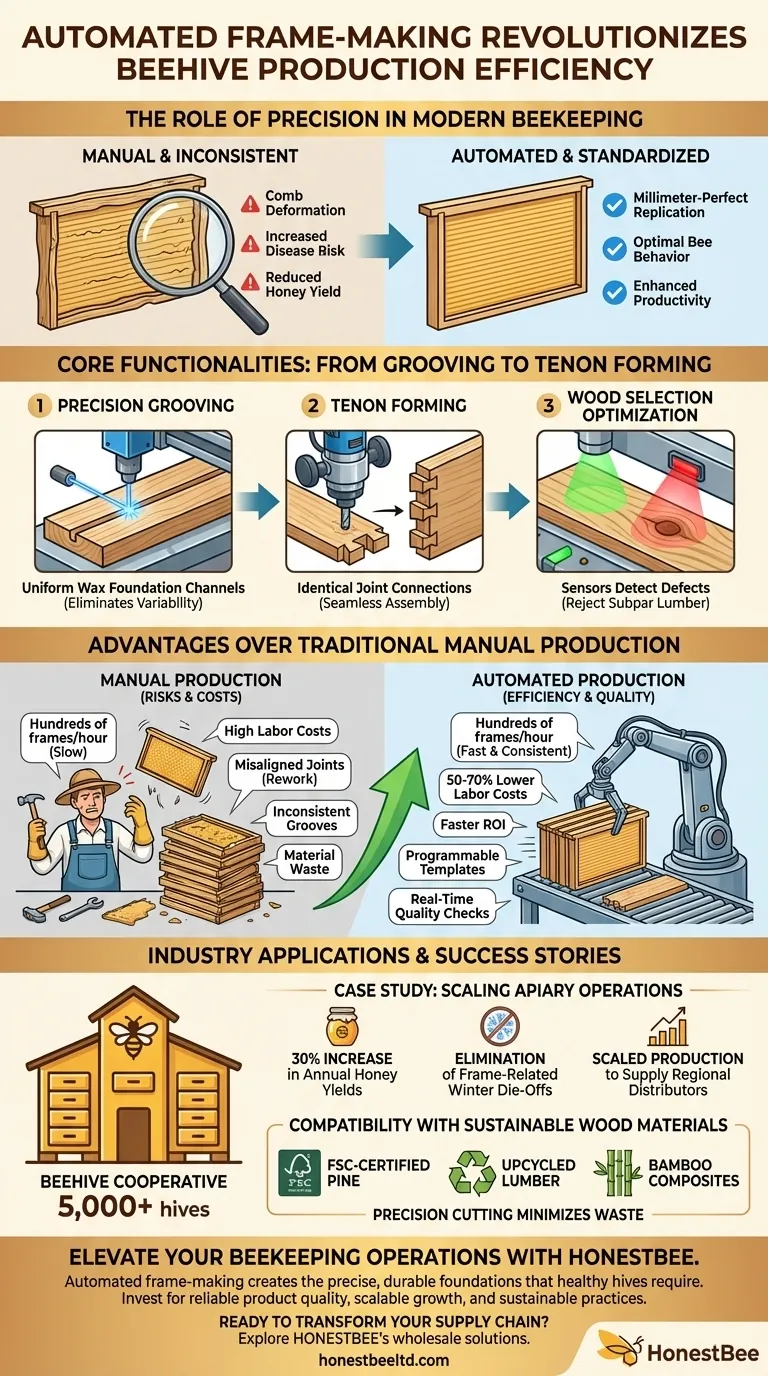

Modern beekeeping demands precision, scalability, and reliability—qualities that manual frame production struggles to deliver. Automated frame-making technologies address these challenges by standardizing critical components like grooving and tenon forming, directly enhancing hive health and operational output. This article explores how precision automation elevates beekeeping equipment quality while reducing labor costs and errors.

The Role of Precision in Modern Beekeeping Equipment

Why Standardized Frames Matter for Hive Health

Beehive frames serve as the structural backbone for honeycomb construction. Inconsistent spacing or uneven grooves—common in handmade frames—can lead to:

- Comb deformation, forcing bees to expend extra energy repairing irregular cells

- Increased disease risk from gaps that harbor pests like wax moths

- Reduced honey yield due to inefficient use of hive space

Automated systems ensure millimeter-perfect replication of frame dimensions, promoting optimal bee behavior and productivity.

Breaking Down Core Functionalities: From Grooving to Tenon Forming

Key automated processes include:

- Precision Grooving: Machines carve uniform wax foundation channels, eliminating the variability of hand-cut grooves.

- Tenon Forming: Automated routers create identical joint connections, ensuring seamless frame assembly.

- Wood Selection Optimization: Sensors detect material defects, rejecting subpar lumber before processing.

These functionalities collectively produce frames that fit perfectly within supers, reducing stress on both bees and beekeepers during inspections.

Advantages Over Traditional Manual Production

Time and Labor Savings: A Cost-Benefit Perspective

A single automated frame-making machine can produce:

- Hundreds of frames per hour—equivalent to a day’s work for multiple artisans

- 50–70% reduction in labor costs for large-scale apiaries

- Faster ROI through consistent output without seasonal labor shortages

For distributors, this translates to reliable inventory turnover and fewer production bottlenecks.

Reducing Human Error in Frame Assembly

Manual production risks:

- Misaligned joints requiring rework

- Inconsistent groove depths affecting comb stability

- Material waste from measurement mistakes

Automation mitigates these issues through programmable templates and real-time quality checks, ensuring every frame meets exact specifications.

Industry Applications and Success Stories

Case Study: Scaling Apiary Operations with Automated Machinery

A midwestern beekeeping cooperative adopted automated frame production to manage 5,000+ hives. Results included:

- 30% increase in annual honey yields from better comb construction

- Elimination of frame-related winter die-offs due to improved insulation from tight-fitting components

- Scaled production capacity to supply regional distributors without outsourcing

Compatibility with Sustainable Wood Materials

Automated systems work seamlessly with:

- FSC-certified pine and upcycled lumber

-

Alternative materials like bamboo composites

Precision cutting minimizes waste, supporting eco-conscious operations.

Elevate Your Beekeeping Operations with HONESTBEE

Automated frame-making isn’t just about speed—it’s about creating the precise, durable foundations that healthy hives require. For commercial apiaries and distributors, investing in this technology means reliable product quality, scalable growth, and sustainable practices.

Ready to transform your beekeeping supply chain? Explore HONESTBEE’s wholesale-focused equipment solutions designed for high-volume, high-efficiency operations.

Visual Guide

Related Products

- Mini Desktop Bee Hive Frame Forming Making Machine

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

Related Articles

- How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

- Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

- Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly