It's a familiar scene in any commercial apiary: a mountain of used frames, caked in old wax, propolis, and the remnants of the last season. The task ahead is daunting—hours of scraping and scrubbing. But the real frustration hits weeks later, when you've done all the work, and yet you still spot signs of chalkbrood or watch a colony struggle to thrive. You followed the steps, but you’re not getting the results. It feels like you're running in place.

The High Cost of "Good Enough" Cleaning

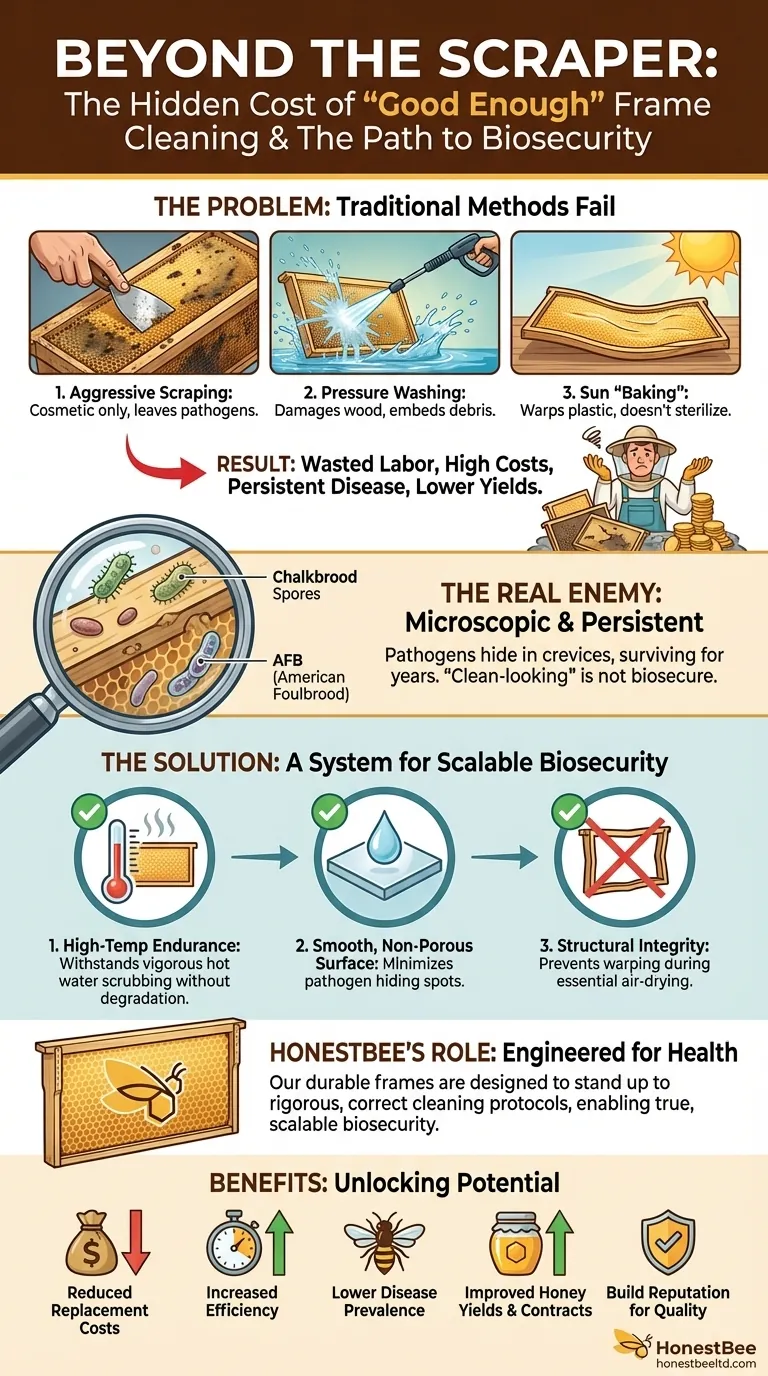

This isn't an isolated problem. Across the industry, apiary managers invest significant labor into frame cleaning, viewing it as a necessary, if tedious, chore. The common approach often involves:

- Aggressive scraping to remove the bulk of wax and cocoons.

- Trying various "shortcuts" like high-pressure washers, which can damage the wood and embed debris deeper into plastic foundations.

- Leaving frames out in the sun to "bake," hoping the heat will handle the rest.

- Ultimately, discarding a high percentage of frames, writing it off as a cost of doing business.

These efforts, while well-intentioned, often miss the point. They treat the symptom (visible wax and debris) while ignoring the disease. The business consequences are severe and quantifiable: wasted labor hours on ineffective processes, increased capital expenditure on replacement frames, and the devastating financial impact of persistent disease, which leads to lower honey yields and jeopardizes valuable pollination contracts.

The Real Enemy: What You Can't See

The turning point comes when you shift your perspective. The goal of cleaning frames isn't just tidiness; it's biosecurity.

The true enemy isn't the visible wax or propolis. It's the microscopic, invisible world of pathogens left behind. Spores from diseases like chalkbrood and the highly resilient American Foulbrood (AFB) can survive for years in the tiny crevices of wood and the cell patterns of plastic foundation.

This is why the common "solutions" fail:

- Scraping alone is merely cosmetic. It leaves behind a minefield of disease vectors.

- Leaving frames in the sun doesn't sterilize them; it simply warps plastic foundation, rendering your expensive equipment useless.

- Using harsh detergents can leave chemical residues that cause bees to reject the frame, wasting the colony's energy and time.

The fundamental truth is this: without a method that systematically removes microscopic pathogens, your cleaning process is failing to protect your operation. You are simply putting a "clean-looking" but contaminated frame back into circulation.

A System for Scalable Biosecurity

To truly solve this problem at a commercial scale, you need more than just hot water and a brush. You need a system. And that system begins with equipment designed for effective sanitation.

A proper biosecurity protocol requires frames that can withstand the only truly effective cleaning method: a vigorous scrub with very hot water. This is where the right equipment becomes a non-negotiable tool. Your frames must be able to:

- Endure repeated, high-temperature washing without degrading or leaching chemicals.

- Offer a smooth, non-porous surface that minimizes the nooks where pathogens can hide.

- Maintain structural integrity to prevent warping during the essential air-drying phase (always in the shade).

This is precisely why HONESTBEE focuses on supplying durable, high-quality frames and foundations. Our products are not just containers for honey; they are engineered as a core component of your apiary's health management system. By providing equipment that stands up to rigorous, correct cleaning protocols, we empower you to move beyond superficial tidiness and implement true, scalable biosecurity. They are built on the understanding that an easy-to-clean frame is a safer, more profitable frame.

Beyond the Fix: Unlocking Your Apiary's Potential

When you solve the frame contamination problem for good, it changes everything. You break the costly cycle of disease, replacement, and lost productivity. Frame cleaning transforms from a dreaded, low-value chore into a strategic, high-value process that protects your investment.

With a reliable sanitation system built on durable equipment, you can:

- Drastically reduce annual equipment replacement costs.

- Increase the speed and efficiency of preparing equipment for spring splits and nucs.

- Lower disease prevalence, leading to stronger, more productive colonies.

- Improve honey yields and secure more reliable pollination contracts thanks to a healthier, more resilient apiary.

- Build a reputation for quality and biosecurity, whether you're producing honey or selling bees.

Stop fighting the same battles season after season. It's time to address the root of the problem and equip your operation for long-term health and profitability. If you're ready to transform your equipment management from a liability into a strategic asset, we can help you build the right foundation. Let's discuss the specific challenges and goals of your apiary. Contact Our Experts.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Professional Stainless Steel Frame Cleaner with Ergonomic Wood Handle

- HONESTBEE Professional Bee Frame Machine for Side Bar Shaping

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

Related Articles

- How to Start Beekeeping Right: Essential Knowledge and Tools for Beginners

- Beekeeping Essentials: How to Choose and Use Supplies for Healthy Colonies

- Why Your Beehive Straps Are a Hidden Liability—And How to Fix It for Good

- Strategic Summer Hive Management: Maximizing Flow Super Efficiency While Preserving Colony Health

- The Comprehensive Benefits of Beekeeping