Beekeepers face a critical challenge: how to process honey efficiently without compromising its natural quality. Honey heating tanks solve this dilemma by combining precise temperature control with scalable designs, ensuring both small-scale beekeepers and commercial operations achieve optimal results.

Optimizing Honey Processing with Heating Tanks

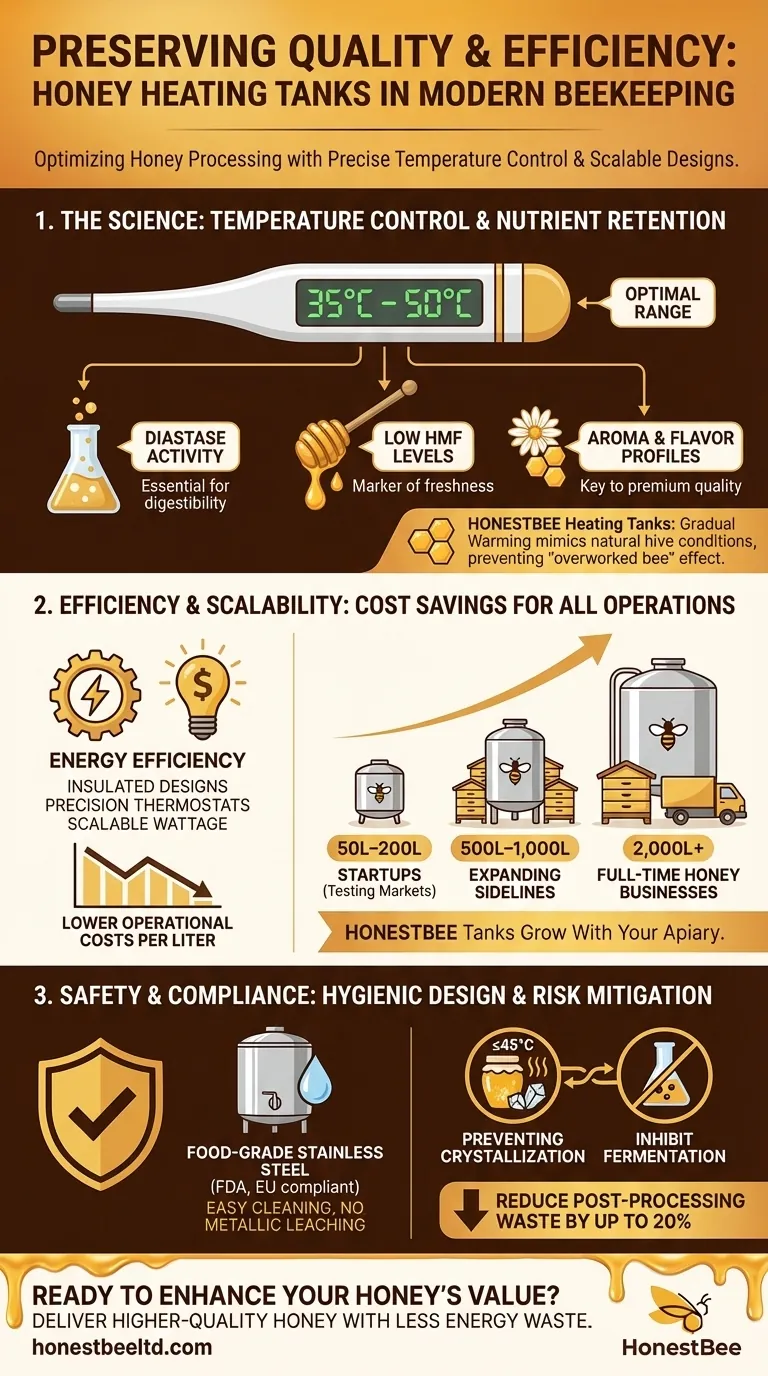

The Science Behind Temperature Control and Nutrient Retention

Honey’s delicate enzymes and beneficial compounds degrade under improper heating. Research shows that maintaining temperatures between 35°C–50°C (approximate range) preserves:

- Diastase activity, essential for honey’s digestibility

- Low HMF levels, a marker of freshness

- Aroma and flavor profiles, key to premium quality

Heating tanks from HONESTBEE use gradual warming to avoid thermal shock, mimicking natural hive conditions. This prevents the "overworked bee" effect, where colonies divert energy from production to hive cooling—a proven factor in yield reduction.

Energy Efficiency: Cost Savings for Small and Large Operations

Modern heating tanks reduce energy waste through:

- Insulated designs that retain heat longer

- Precision thermostats to avoid overheating cycles

- Scalable wattage options, matching tank size to need

For commercial apiaries, this translates to lower operational costs per liter of honey processed, while hobbyists benefit from reduced electricity bills.

Scalability: Adapting to Beekeeping Growth Demands

From hobbyist batches to industrial volumes, modular systems allow seamless upgrades:

- Small tanks (50L–200L): Ideal for startups testing markets

- Mid-range (500L–1,000L): Fits expanding sidelines

- Commercial (2,000L+): Supports full-time honey businesses

A HONESTBEE heating tank grows with your apiary, eliminating the need for costly replacements as production scales.

Ensuring Safety and Compliance in Honey Production

Hygienic Design and Regulatory Standards

Food-grade stainless steel construction ensures:

- Easy cleaning, preventing bacterial buildup

- Compliance with global food safety regulations (e.g., FDA, EU standards)

- No metallic leaching, preserving honey’s purity

Risk Mitigation: Preventing Crystallization and Fermentation

Controlled heating tackles two major honey spoilage risks:

- Crystallization: Gentle warming (≤45°C) dissolves sugar crystals without scorching.

- Fermentation: Consistent temperatures inhibit wild yeast activation.

By maintaining these parameters, beekeepers reduce post-processing waste by up to 20% (industry estimate), protecting profit margins.

Ready to Enhance Your Honey’s Value?

HONESTBEE’s heating tanks help beekeepers and distributors deliver higher-quality honey with less energy waste. Whether you’re bottling artisanal batches or supplying supermarkets, our scalable solutions protect your product—and your bottom line.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

Related Articles

- How Honey Processing Affects Nutrition: Science-Backed Insights for Healthier Choices

- How to Prevent and Manage Honey Crystallization in Flow Hives: A Beekeeper’s Guide

- The Unseen Battle in Every Honey Bucket: Heat, Time, and Quality

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines