The Beekeeper's Dilemma

Imagine a warehouse filled with 5-gallon buckets of this past season's harvest. Hundreds of pounds of honey, pure and raw. But it’s not liquid gold anymore. It’s solid, opaque, and crystallized.

This isn't a sign of spoilage. It's the mark of authentic, unprocessed honey. But it's also a logistical nightmare. You can't bottle it, sell it, or use it.

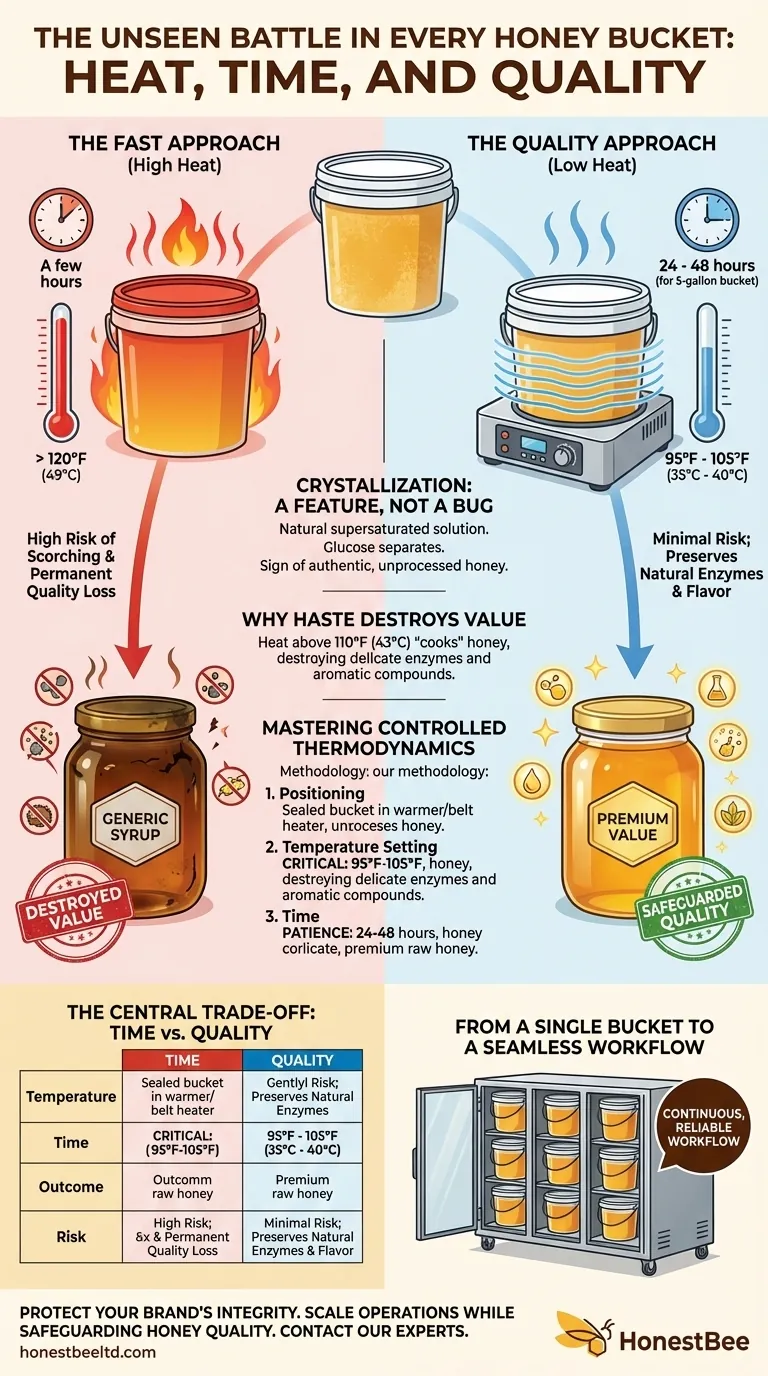

The immediate, human impulse is to solve the problem quickly. To apply high heat, melt the crystals fast, and get the production line moving. This temptation—to trade patience for speed—is the single greatest threat to your honey's quality.

Crystallization: A Feature, Not a Bug

Honey is a supersaturated solution, packed with more sugar (mostly glucose and fructose) than its water content can technically hold indefinitely. Over time, glucose separates from the water, forming tiny crystals.

This process is completely natural. It's a sign that the honey hasn't been pasteurized or heavily processed. But reversing it requires a deep understanding of what you're trying to protect.

Why Haste Destroys Value

Within that thick, crystalline structure are delicate enzymes and volatile aromatic compounds. These are the elements that give honey its unique flavor profile, its health benefits, and its premium value.

High heat (anything above 110°F or 43°C) is a blunt instrument. It doesn't just melt the glucose crystals; it "cooks" the honey, destroying those beneficial enzymes and driving off the complex flavors. The result is a darker, often generic-tasting syrup. You've solved the logistical problem but destroyed the very essence of the product.

Mastering Controlled Thermodynamics

The goal is not simply to melt honey. It's to persuade the glucose crystals to dissolve back into the solution without collateral damage. This is a process governed not by force, but by finesse. A dedicated honey warmer is the tool designed for this precise negotiation.

The Principle of Gentle Persuasion

The methodology is one of controlled patience.

- Positioning: Place your sealed bucket or container into the warming unit. For belt-style heaters, wrap it securely around the container's midsection.

- Temperature Setting: This is the most critical step. Set the thermostat low, ideally between 95°F and 105°F (35°C to 40°C). This range is warm enough to encourage liquefaction but cool enough to protect the honey's integrity.

- Time: Walk away. A 5-gallon (60 lb) bucket can take 24 to 48 hours to liquefy completely. Resist the urge to crank up the heat. Patience is the primary ingredient.

The Dangers of Uncontrolled Heat—microwaves, stovetops, or boiling water—are that they create intense hot spots, scorching parts of the honey long before the center has even begun to melt.

The Central Trade-Off: Time vs. Quality

Every beekeeper must navigate this fundamental balance. Using a honey warmer is a conscious choice to prioritize quality over speed.

| Factor | The Fast Approach (High Heat) | The Quality Approach (Low Heat) |

|---|---|---|

| Temperature | > 120°F (49°C) | 95°F - 105°F (35°C - 40°C) |

| Time | A few hours | 24 - 48 hours for a 5-gallon bucket |

| Outcome | Liquefied honey with degraded enzymes, altered flavor, darker color. | Fully preserved raw honey with its natural enzymes and flavor. |

| Risk | High risk of scorching and permanent quality loss. | Minimal risk; safeguards the product's premium value. |

From a Single Bucket to a Seamless Workflow

For a hobbyist, managing one or two jars is simple. But for a commercial apiary or distributor, the challenge is scale. How do you apply this principle of patience to hundreds of buckets without creating a massive bottleneck?

This is where professional equipment becomes essential. A dedicated warming cabinet that holds multiple buckets allows you to create a continuous, reliable workflow. As one batch is being bottled, the next is already gently warming, ensuring you have a consistent supply of perfectly liquefied honey ready to go.

This isn't just about buying a heater; it's about investing in a system that protects the quality and reputation you've worked so hard to build. For operations focused on efficiency and scale, the durable, purpose-built equipment from HONESTBEE provides the consistency needed to manage large volumes without compromise.

Your product's integrity is your brand. Ensuring it's handled correctly from hive to bottle is the final, crucial step in your craft. If you're ready to scale your operations while safeguarding the quality of your honey, we can help. Contact Our Experts

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

Related Articles

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines

- Heat, Honey, and Haste: The Physics of Preserving Liquid Gold

- The Unseen Cost of Manual Honey Filling: A Case for Automation

- How to Optimize Steam Wax Melting for Higher Yields and Safer Operations

- How Honey Heating Tanks Preserve Quality and Efficiency in Modern Beekeeping