A Seemingly Simple Task

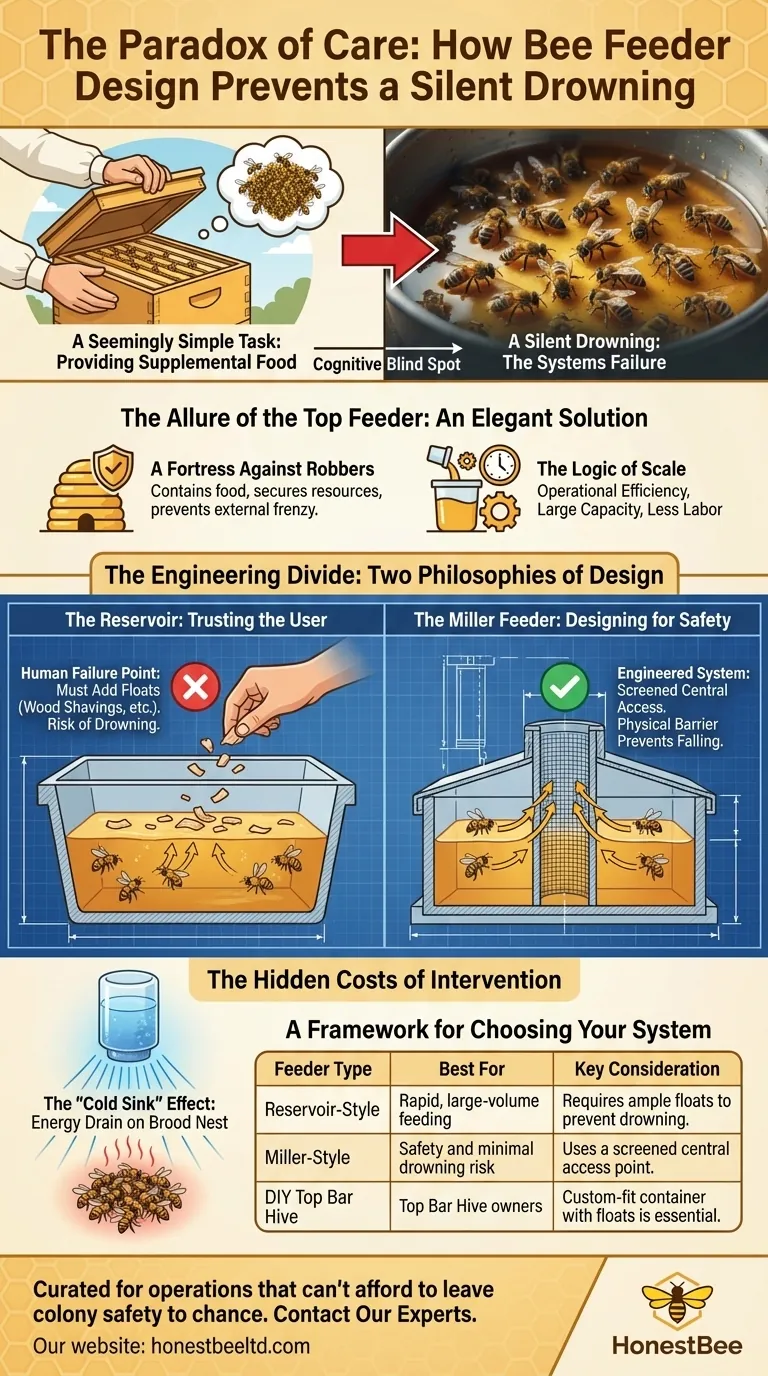

Imagine opening a hive to check on a colony you've been carefully nurturing. You’re providing supplemental food—sugar syrup—to help them through a nectar dearth. But instead of a thriving cluster of bees, you find a tragedy.

Thousands of them are dead, floating in the very syrup meant to save them.

This isn't a rare accident. It's a systems failure. It’s the result of a design choice that prioritizes one form of convenience while ignoring a catastrophic, hidden risk. We, as humans, are wired to optimize for the obvious—easy refills, large capacity—while underestimating the silent, cumulative dangers. In beekeeping, this cognitive blind spot can be lethal.

The Allure of the Top Feeder: An Elegant Solution

There’s a reason top hive feeders are a cornerstone of modern apiary management. When designed correctly, they solve fundamental problems with an elegant efficiency.

A Fortress Against Robbers

The sweet scent of sugar syrup is an open invitation to chaos. It attracts robbing bees from neighboring colonies, wasps, and ants, igniting a war right at the hive’s entrance. By containing the food source entirely within the hive, a top feeder acts as a fortress. It keeps the colony’s resources secure and prevents the frenzy that external feeders can trigger.

The Logic of Scale

For a commercial operation, labor is cost. Top feeders, with their large one-to-three-gallon capacities, are built for operational efficiency. They allow for rapid, large-volume feeding, ensuring a consistent food supply without requiring daily visits. You can service dozens of hives with minimal disruption to the colony's critical brood-rearing activities below.

The Engineering Divide: Two Philosophies of Design

The central challenge of a top feeder is simple: give bees access to liquid food without letting them drown in it. The way a feeder solves this problem reveals its core design philosophy.

The Reservoir: Trusting the User

The simplest design is a large, open tray, like a basin, that sits atop the hive. It’s efficient and holds a massive volume of syrup.

But its design is fundamentally incomplete. Its safety rests entirely on the beekeeper’s shoulders. To prevent drowning, you must add floats—wood shavings, pine needles, corks, or custom screens—to give the bees a safe place to stand. This system has a critical human failure point. If the floats are forgotten, insufficient, or become waterlogged and sink, the feeder becomes a death trap.

The Miller Feeder: Designing for Safety

A Miller-style feeder represents a different philosophy. It is an engineered system that removes the risk by design.

Instead of a single open pool, the syrup is held in channels. Bees access it by climbing up a central, screen-covered "chimney." They can drink through the mesh, but a physical barrier makes it impossible for them to fall into the main reservoir. It’s an elegant solution that anticipates failure and designs it out of the system. It doesn’t just trust the user to be perfect; it makes the system inherently safe.

The Hidden Costs of Intervention

Even the best-designed tools have trade-offs. Understanding them is key to effective management.

The most significant cost, of course, is the drowning hazard in poorly designed or managed feeders. A single oversight can wipe out thousands of foragers, crippling a colony's ability to recover.

But there's a more subtle risk: the "cold sink" effect. Placing a large volume of cold syrup directly above the bee cluster, especially in the cooler weather of spring or fall, is like putting an ice pack on the roof of a nursery. It forces the colony to expend precious energy just to maintain the critical temperature of the brood nest below.

A Framework for Choosing Your System

The right feeder isn’t a matter of "good" or "bad," but of aligning your equipment with your operational goals and risk tolerance. Your choice is a strategic one.

| Feeder Type | Best For | Key Consideration |

|---|---|---|

| Reservoir-Style | Rapid, large-volume feeding | Requires ample floats (e.g., wood shavings) to prevent drowning. |

| Miller-Style | Safety and minimal drowning risk | Uses a screened central access point for safe bee access. |

| DIY Top Bar Hive | Top Bar Hive owners | A custom-fit container with plenty of floats is essential. |

For commercial apiaries, where efficiency and colony health are paramount, choosing a feeding system is not a trivial decision. It's an investment in operational stability and risk management.

At HONESTBEE, we understand this balance between elegant design and practical reliability. Our wholesale supplies are curated for operations that can't afford to leave colony safety to chance. If you're looking to implement feeding systems that protect your colonies and your bottom line, Contact Our Experts.

Visual Guide

Related Products

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Professional Hive Front Entrance Bee Feeder

- HONESTBEE Round Hive Top Bee Feeder for Syrup

- HONESTBEE Professional Entrance Bee Feeder Hive Nutrition Solution

- Boardman Entrance Bee Feeder Durable Galvanized Steel and Wood Construction for Beekeeping

Related Articles

- The Winter Fortress: Engineering Colony Survival with the Hive Top Feeder

- The Benevolent Trap: Why Your Bee Feeder's Design is a Matter of Life and Death

- The Slippery Wall Problem: A Fatal Design Flaw in Bee Feeders

- The Paradox of Plenty: Why Warm Winters Are a Silent Threat to Bee Colonies

- Hive Security: Why Bee Feeder Placement is a Matter of Life and Death