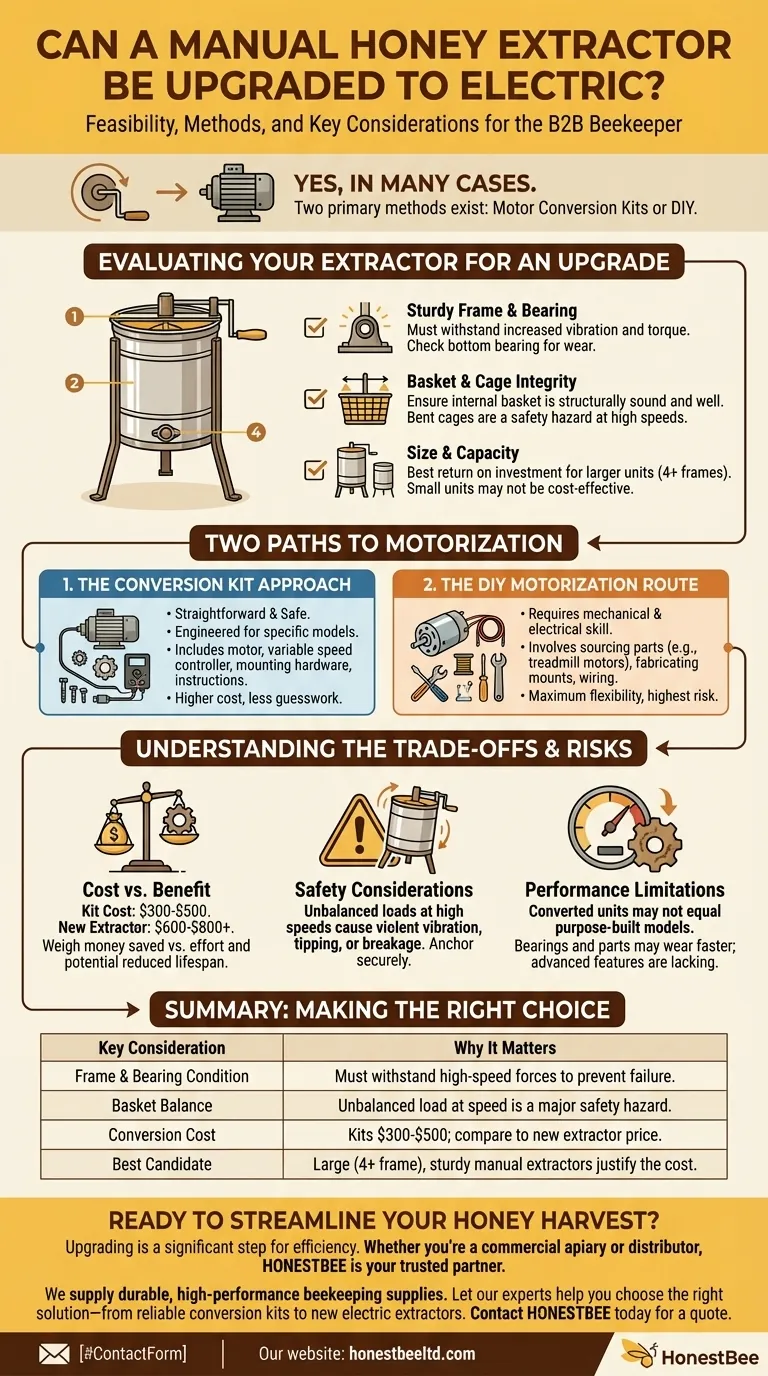

Yes, in many cases, a manual honey extractor can be upgraded to an electric one. This is typically achieved in one of two ways: by installing a purpose-built motor conversion kit designed for your specific model, or through a do-it-yourself (DIY) approach that involves sourcing and fitting a motor and speed controller. The feasibility and wisdom of this upgrade, however, depend heavily on the condition of your extractor and your technical comfort level.

While motorizing a manual extractor is a viable way to reduce physical labor, the core decision is not just about if you can, but if you should. You must weigh the cost and safety implications against the condition of your current equipment and the price of a new, purpose-built electric extractor.

Evaluating Your Extractor for an Upgrade

Before considering a motor, you must assess if your extractor's frame and mechanical parts can handle the increased speed and stress. An electric motor will push your equipment far beyond its original design limits.

The Importance of a Solid Frame and Bearing

A motor will introduce significant vibration and torque. Your extractor must have a sturdy, rigid frame and legs that can be securely anchored to prevent "walking" or tipping over during operation.

Critically, inspect the bottom bearing. This is the point of highest stress. If it is worn, corroded, or not designed for high speeds, it will fail quickly under motor power, potentially destroying the extractor.

Basket and Cage Integrity

The internal basket that holds the honey frames must be well-balanced and structurally sound. A weak or bent cage can easily deform or break apart at high RPMs, creating a serious safety hazard. Manually spinning a slightly unbalanced load is manageable; at electric speeds, it is not.

Extractor Size and Capacity

Consider if the capacity of your extractor justifies the expense. Investing several hundred dollars to motorize a small two or three-frame unit may not be cost-effective. The greatest return on investment comes from upgrading larger manual extractors (four frames and up).

Two Paths to Motorization

You have two primary options for converting your extractor, each with distinct advantages and requirements.

The Conversion Kit Approach

This is the most straightforward and safest method. Conversion kits are sold by beekeeping suppliers and are engineered for specific extractor models.

A typical kit includes the motor, a variable speed controller, mounting hardware, and instructions. While more expensive than a DIY solution, it removes the guesswork and ensures the components are properly matched.

The DIY Motorization Route

This path requires significant mechanical and electrical skill. It involves sourcing your own parts, fabricating mounts, and wiring the system correctly.

Commonly, beekeepers adapt DC motors (like those from old treadmills) and use a Pulse Width Modulation (PWM) controller to manage the speed. This offers maximum flexibility but also carries the highest risk if not executed with precision and a deep understanding of the forces involved.

Understanding the Trade-offs and Risks

Motorizing your extractor is not a simple upgrade. It introduces new costs and potential dangers that must be carefully considered.

Cost vs. Benefit

A motor conversion kit can cost between $300 and $500. A brand new, entry-level electric extractor might start around $600 to $800. You must ask if the money saved is worth the effort and the potential for reduced lifespan on a converted unit.

Safety Considerations

An extractor with an unbalanced load is the single biggest risk. At high speeds, this can cause the machine to vibrate violently, tip over, or even fly apart. Always ensure frames are evenly matched by weight and that the extractor is bolted to a heavy, stable platform.

Performance Limitations

A converted manual extractor will likely never perform as well as a purpose-built electric model. The bearings, shaft, and basket were not designed for sustained high-speed use and may wear out faster. You also won't have advanced features like pre-programmed extraction cycles.

Making the Right Choice for Your Operation

Deciding whether to upgrade or buy new depends entirely on your equipment, skills, and long-term goals.

- If your primary focus is saving labor on a sturdy, larger extractor: A well-matched conversion kit is an excellent and cost-effective solution for the hobbyist with a reliable machine.

- If your primary focus is long-term reliability and efficiency: Investing in a new, purpose-built electric extractor is the safer and more durable choice, especially if you plan to expand your operation.

- If your manual extractor is small, old, or shows any signs of wear: Do not attempt an upgrade; the risks and costs outweigh any potential benefit, and your money is better saved for a new machine.

By carefully evaluating your equipment and goals, you can make a confident decision that streamlines your harvest and protects your investment.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Frame & Bearing Condition | Must withstand high-speed vibration and torque to prevent failure. |

| Basket Balance | An unbalanced load at high speed is a major safety hazard. |

| Conversion Cost | Kits cost $300-$500; weigh this against the price of a new electric extractor. |

| Best Candidate | Large (4+ frame), sturdy manual extractors justify the upgrade cost. |

Ready to Streamline Your Honey Harvest?

Upgrading your extraction process is a significant step toward greater efficiency. Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE is your trusted partner.

We supply durable, high-performance beekeeping supplies and equipment through wholesale-focused operations. Let our experts help you choose the right solution—from reliable conversion kits to new, purpose-built electric extractors—that will save you time and labor for seasons to come.

Contact HONESTBEE today to discuss your needs and get a quote. Let's build a more productive operation together.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- Why Is Efficient Centrifugal Extraction Technology Necessary for Evaluating Pesticide Impact on Honeybee Life Cycles?

- What role does a centrifugal honey extractor play? Boost Yield and Protect Your Bees

- Why is specialized suction extraction equipment necessary for harvesting stingless bee honey? Protect Hives & Purity

- What is a fun and easy alternative to using a honey extractor for harvesting honey? Try the Crush and Strain Method

- How can a beekeeper perform a manual test to check if uncapped honey is ready for harvest? Master the Shake Test

- What are the advantages of a stainless steel honey extractor? Ensure Honey Purity & Long-Term Value

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- What is the importance of using a high-power stainless steel honey extractor? Boost Professional Apiary Efficiency