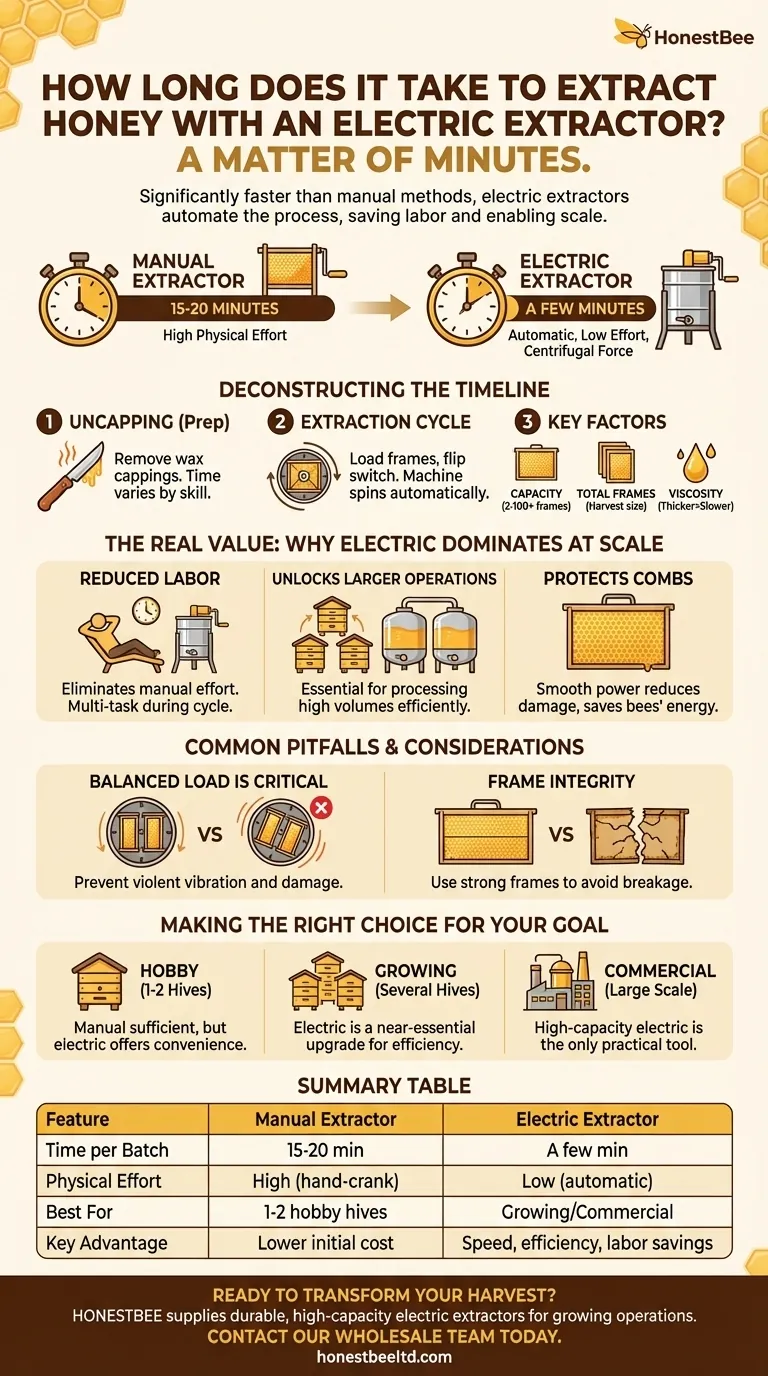

The short answer is a matter of minutes. While a manual, hand-cranked extractor can take 15 to 20 minutes to process a few frames, a comparable electric honey extractor completes the same task automatically in just a few minutes per batch. This significant speed increase is a primary reason beekeepers upgrade.

The true value of an electric extractor isn't just the minutes saved per cycle, but the dramatic reduction in physical labor and the ability to efficiently process large volumes of honey, making it an essential tool for any beekeeper with more than a few hives.

Deconstructing the Honey Extraction Timeline

The time it takes to spin honey is only one piece of the puzzle. Understanding the entire process reveals where the real efficiencies are gained.

Preparation: The Non-Negotiable First Step

Before any extraction begins, you must uncap the honeycomb. This involves using a heated knife or other tool to slice off the thin wax cappings that bees use to seal the filled honey cells. This step's duration depends entirely on your skill and tooling, not the extractor type.

The Extraction Cycle: How It Works

Once placed inside the extractor, the machine uses centrifugal force to sling the honey out of the uncapped cells. With an electric model, you simply load the frames, balance the machine, and flip a switch. The machine spins up to speed and completes the cycle automatically.

Key Factors Influencing Total Time

The "few minutes" per cycle can vary based on several factors:

- Extractor Capacity: Models range from holding just two frames to over 100 in large commercial operations.

- Total Number of Frames: The primary time determinant is your total harvest size. An electric model's efficiency becomes obvious when processing dozens of frames.

- Honey Viscosity: Thicker, cooler honey will take slightly longer to extract than warmer, more fluid honey.

The Real Value: Why Electric Dominates at Scale

Speed is an advantage, but the fundamental benefits of an electric extractor become clear as your beekeeping operation grows.

Drastically Reduced Physical Labor

The single greatest benefit is the elimination of manual effort. You are free to uncap the next batch of frames or handle other tasks while the machine does all the work. This massively reduces fatigue during a long harvest day.

Unlocking Larger Operations

Electric extractors are what make small, medium, and large-scale beekeeping feasible. Their ability to process a high volume of frames quickly is essential for anyone managing more than one or two backyard hives.

Protecting Your Combs

The smooth, controlled power of an electric motor can reduce the risk of damaging delicate honeycombs. This is crucial because it allows the bees to refill the undamaged frames immediately, saving them significant time and energy.

Common Pitfalls and Considerations

To ensure a smooth and successful extraction, you must be aware of the operational requirements.

The Critical Need for a Balanced Load

You must ensure the frames loaded into the extractor are of similar weight and placed opposite each other. An unbalanced extractor can vibrate violently, potentially damaging the machine, the frames, and creating a safety hazard.

Frame Integrity is Non-Negotiable

Only use frames with strong wire or plastic foundation. Older, unsupported frames are likely to break apart under the powerful centrifugal force of an electric extractor, creating a difficult mess to clean up.

The Initial Investment

The primary trade-off for the convenience and efficiency of an electric extractor is its cost. It represents a more significant financial investment compared to a manual model, which must be weighed against your operational scale.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on the scale of your beekeeping.

- If your primary focus is a hobby with 1-2 hives: A manual extractor is often sufficient, but an electric model offers significant convenience and saves physical effort.

- If your primary focus is a growing operation with several hives: An electric extractor is a near-essential upgrade that will save you hours of labor and dramatically improve your harvest day efficiency.

- If your primary focus is a commercial or large-scale operation: A high-capacity electric extractor is the only practical tool for processing the required volume in a timely manner.

Choosing the right tool for your specific needs transforms honey extraction from a laborious chore into an efficient and rewarding process.

Summary Table:

| Feature | Manual Extractor | Electric Extractor |

|---|---|---|

| Time per Batch | 15-20 minutes | A few minutes |

| Physical Effort | High (hand-cranking) | Low (automatic) |

| Best For | 1-2 hobby hives | Growing/Commercial operations |

| Key Advantage | Lower initial cost | Speed, efficiency, labor savings |

Ready to transform your harvest from a chore into an efficient process?

For commercial apiaries and beekeeping equipment distributors, the right electric extractor isn't a luxury—it's a necessity for profitability and scale. HONESTBEE supplies the durable, high-capacity electric extractors and equipment that growing operations rely on.

Contact our wholesale team today to discuss how our solutions can save you time, reduce labor, and increase your honey processing capacity.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the easiest way to extract honey? Master the Simple Crush-and-Strain Method

- What is the purpose of honey extraction in beekeeping? Maximize Hive Productivity & Honey Yield

- What are the core functions and advantages of using centrifugal honey extractors? Maximize Yield with Comb Preservation

- Does the type of extractor impact the honeycomb? Choose the Right Tool to Maximize Honey Yield

- How does a honey extractor work to harvest honey? Master the Centrifugal Force for Efficient Beekeeping

- How do professional honey extraction and filtration machines contribute to honey quality? Scale Your Apiary Success

- Why are industrial honey extractors necessary? Boost Efficiency for 300-500 Colony Commercial Apiaries

- What role do industrial honey extractors play for beekeepers with physical limitations? Maximize Yield & Ease