At its core, a beehive operates as a superorganism with a remarkable ability to control its internal climate. Honey bees generate heat by vibrating their flight muscles in a tight cluster to survive the cold, and they cool the hive by fanning their wings over droplets of water to create evaporative cooling. Expanded Polystyrene (EPS) insulation simply makes this job easier, acting as a powerful thermal buffer that dramatically reduces the amount of energy the colony must expend to maintain its ideal temperature.

The central challenge for any bee colony is energy management. By minimizing the constant energy drain of fighting external temperatures, EPS insulation allows the bees to redirect their efforts from simple survival to vital tasks like raising brood, foraging, and producing honey.

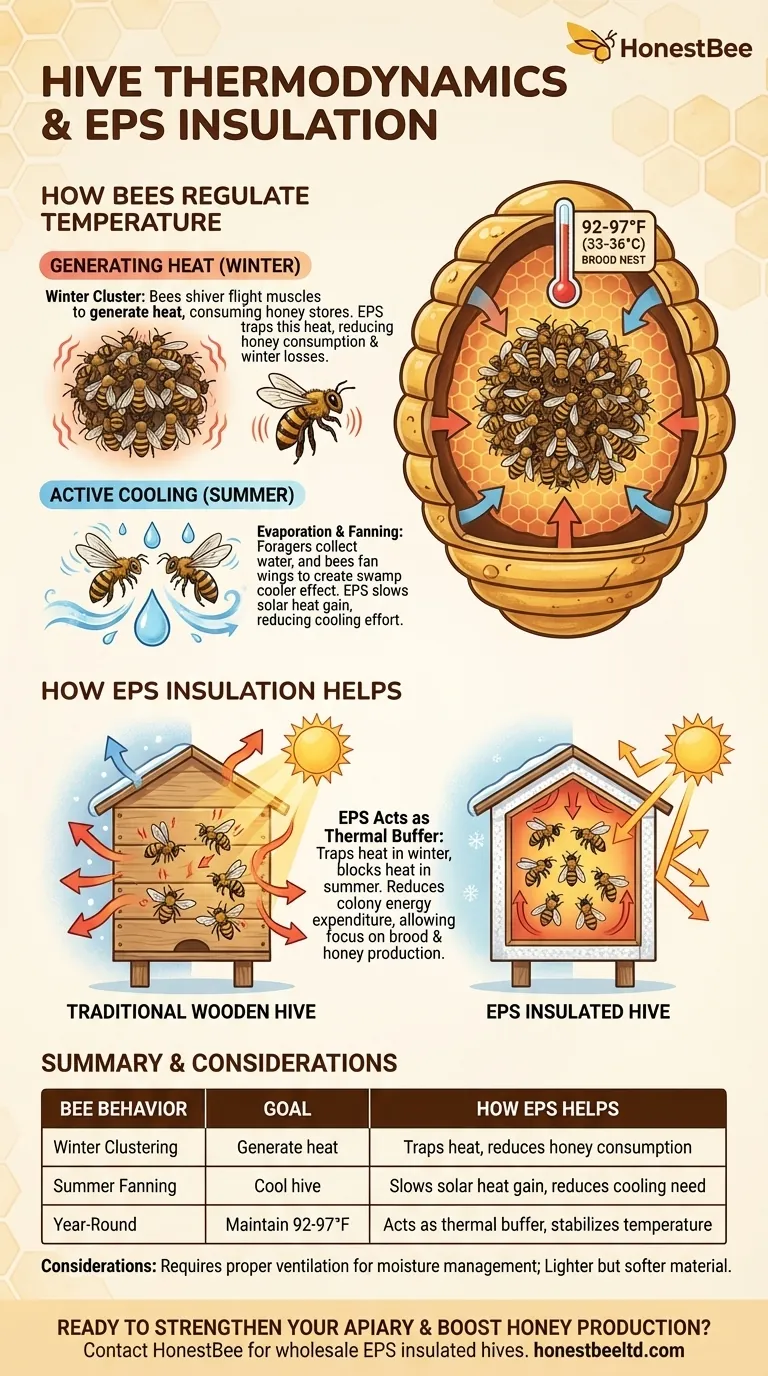

The Bee Colony's Internal Thermostat

A honey bee colony maintains the center of its brood nest at a stable 92-97°F (33-36°C), regardless of the weather outside. This precision is not incidental; it is a biological necessity for raising healthy young bees, and it comes at a significant energetic cost.

Generating Heat: The Winter Cluster

To survive the cold, bees form a dense "winter cluster." Bees on the inside of this cluster consume honey and then vibrate their powerful thoracic (flight) muscles without moving their wings. This coordinated shivering generates a tremendous amount of heat.

The bees constantly rotate positions, moving from the cold outer layer of the cluster to the warm interior to eat and generate heat. This process is effective but burns through their winter honey stores at a rapid rate.

Active Cooling: Evaporation and Fanning

In intense summer heat, the opposite problem occurs. Forager bees switch from collecting nectar to collecting water. They spread this water on the surfaces of the honeycomb and at the hive entrance.

Simultaneously, other bees position themselves and fan their wings vigorously, creating a powerful airflow. This forced convection evaporates the water, creating a natural "swamp cooler" effect that lowers the internal temperature of the hive and protects the delicate wax comb from melting.

How EPS Insulation Rewrites the Energy Equation

An insulated hive does not create heat or cold; it simply slows down the transfer of heat between the inside and the outside. This small change has profound consequences for the colony's energy budget.

A Buffer Against the Cold

An EPS hive acts like a high-performance winter jacket. The heat generated by the winter cluster is trapped within the hive, drastically reducing the rate at which it escapes into the cold air.

This means the bees need to vibrate less and consume far less honey to maintain their core temperature. The result is lower winter losses and a stronger, more populous colony in the spring.

Mitigating Summer Heat

Insulation works both ways. On a hot, sunny day, an EPS hive slows the rate at which solar radiation heats the hive interior. This gives the bees a much larger buffer before the internal temperature rises to a dangerous level.

This reduces the frequency and intensity of cooling behaviors, freeing up foragers to collect nectar instead of water and conserving the colony's energy for more productive tasks.

Understanding the Trade-offs

While highly effective, EPS hives are not a universal solution without considerations. Objectivity requires acknowledging the complete picture.

Moisture Management

Superior insulation means the warm, moist air created by the bees is more likely to condense on cold inner surfaces. Without proper ventilation, this condensation can drip down onto the cluster, chilling the bees and promoting mold. Managing ventilation is therefore more critical in an EPS hive than in a draftier wooden one.

Durability and Handling

EPS is significantly lighter than wood, making it easier to lift. However, it is also softer and can be more easily damaged by hive tools or pests like wax moths if the colony is not strong enough to defend its space.

Making the Right Choice for Your Apiary

The decision between hive materials depends entirely on your climate and beekeeping goals. Understanding the energy dynamics is key to making an informed choice.

- If your primary focus is maximizing winter survival: EPS provides a clear and significant advantage by minimizing heat loss and reducing the colony's food consumption.

- If your primary focus is honey production: The energy saved by the bees on thermoregulation in both summer and winter can be directly converted into a larger honey surplus.

- If your primary focus is a low-cost, traditional setup: Well-managed wooden hives remain perfectly viable, but you must accept that the colony will expend more of its own resources to manage its environment.

By understanding the hive's energy economy, you are empowered to make the best decision for the long-term health and productivity of your colonies.

Summary Table:

| Bee Behavior | Goal | How EPS Insulation Helps |

|---|---|---|

| Winter Clustering | Generate heat to survive cold | Traps heat, reduces honey consumption, lowers winter losses |

| Summer Fanning | Cool hive via water evaporation | Slows solar heat gain, reduces need for cooling, frees up foragers |

| Year-Round | Maintain brood nest at 92-97°F (33-36°C) | Acts as a thermal buffer, stabilizing internal hive temperature |

Ready to strengthen your apiary and boost honey production?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-quality, wholesale-priced EPS insulated hives. By reducing your colonies' energy expenditure on temperature control, our equipment directly supports stronger spring populations and greater honey yields.

Contact our wholesale experts today to discuss how our insulated hive solutions can benefit your operation.

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Grade Foldable Beehive Handles

- HONESTBEE Classic Pry Bar Hive Tool with High Visibility Finish for Beekeeping

People Also Ask

- How does the integration of foam insulation layers contribute to the thermal stability of a solar-heated beehive?

- How do wall thickness and material selection influence the thermal stability of a beehive? Optimize Winter Survival

- How does the ventilation design in polyurethane beehives work? Optimize Colony Health with Precision Airflow

- How do high-insulation foam beehives contribute to colony productivity in extreme climates? Boost Honey Yields Today

- What are the maintenance requirements for polystyrene hives compared to wooden hives? Minimize Your Beekeeping Labor

- Is polystyrene bee hive better than wood? Superior Insulation for Healthier Bees & More Honey

- What is the function of foam plastic as an outer wall material in smart beehive construction? Maximize Thermal Efficiency

- What factors should beekeepers consider when choosing between wooden and polystyrene hives? Maximize Bee Health and Honey Production