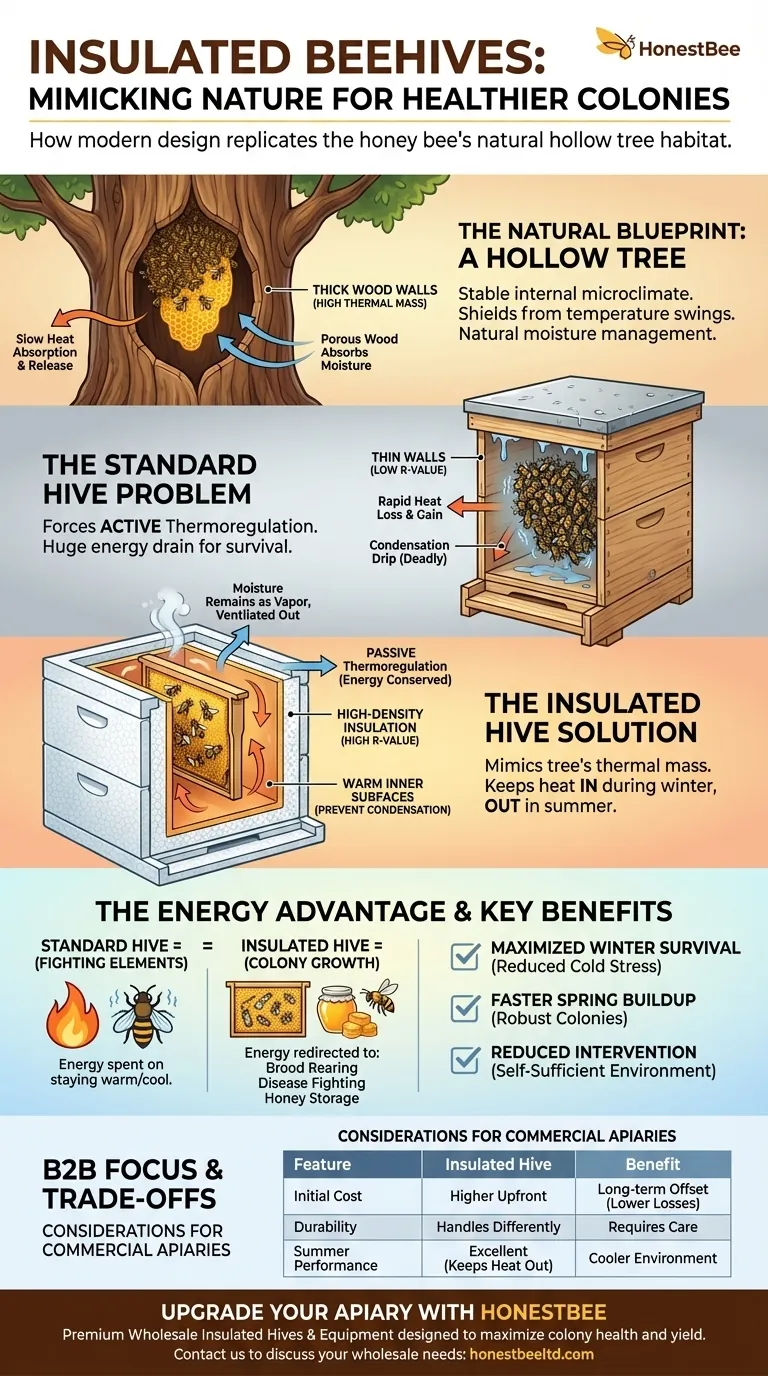

Insulated beehives fundamentally mimic a honey bee's natural habitat by replicating the thick, thermally stable walls of a hollow tree. This design creates a stable internal microclimate that shields the colony from extreme temperature swings and, crucially, helps manage the dangerous moisture that bees produce. It allows the hive to function less like a thin-walled box and more like the natural log cavity bees evolved to inhabit over millions of years.

The core problem with standard, thin-walled wooden hives is that they force bees to expend enormous energy simply surviving the environment. Insulation gives that energy back to the bees, allowing them to redirect it from temperature control to critical tasks like raising brood, fighting disease, and storing honey.

The Natural Blueprint: A Hollow Tree

To understand insulated hives, we must first look to the honey bee's preferred natural dwelling: a cavity in a large, living tree. This environment provides several key survival advantages.

Superior Thermal Mass

A hollow tree possesses thick walls of wood, which have significant thermal mass. This means the wood absorbs and releases heat very slowly. It acts as a massive buffer, protecting the bee cluster from rapid daily temperature fluctuations and the brutal cold of winter nights.

Natural Moisture Management

The porous wood of a tree wall can absorb excess water vapor from the bees' respiration, acting like a natural dehumidifier. This prevents moisture from condensing into liquid water on cold surfaces and dripping down onto the winter cluster—a common cause of colony death.

The Energy Conservation Equation

In a stable, well-insulated home, the bee cluster needs to burn far less honey to generate the heat required to keep the queen and brood at their critical temperature (around 95°F / 35°C). This conserved energy is the colony's most valuable resource.

How Insulated Hives Replicate Nature

Modern insulated hives are engineered to provide the benefits of a tree hollow without the weight and impracticality. They achieve this by focusing on the same core principles of thermal stability and moisture control.

Mimicking Thermal Mass with Modern Materials

Insulated hives, often made from high-density expanded polystyrene (EPS), replicate the high R-value (a measure of thermal resistance) of a thick tree trunk. While a standard 3/4-inch pine box has an R-value of about R-1, a typical insulated hive wall can be R-6 to R-8 or even higher.

This insulation dramatically slows heat transfer. In winter, it keeps the colony's warmth inside, and in summer, it keeps the sun's intense heat outside.

Passive vs. Active Temperature Regulation

A thin wooden hive forces the bees into a state of active thermoregulation. They must constantly and rapidly generate heat in winter or fan furiously to cool the hive in summer, burning through vital resources.

An insulated hive creates a system of passive thermoregulation. The hive itself does most of the work of buffering against the external environment, freeing up the bees' energy for other tasks.

Solving the Condensation Problem

Condensation is a major killer of wintering colonies. It occurs when warm, moist air from the bee cluster hits a cold inner surface of the hive, turning vapor into liquid water.

Because insulation keeps the hive's inner walls warmer, their surface temperature stays above the dew point. Moisture remains as vapor, which can then be properly ventilated out of the hive, keeping the cluster dry and healthy.

Understanding the Trade-offs

While insulation offers significant biological advantages for the bees, it's important to consider the practical trade-offs for the beekeeper.

The Initial Cost Factor

Insulated hives typically have a higher upfront cost than standard wooden Langstroth equipment. However, this cost can be offset over time through lower winter losses and potentially less need for supplemental feeding.

Material Durability and Handling

Polystyrene is lighter than wood but can be damaged by hive tools if the beekeeper is not careful. While durable, it does not have the same resilience to scraping and prying as a wooden box.

The Myth of Overheating

A common misconception is that insulation will cause the hive to overheat in the summer. In reality, insulation works both ways: it is just as effective at keeping heat out as it is at keeping heat in. Paired with a properly ventilated top, an insulated hive provides a much cooler and less stressful environment during a heatwave.

Making the Right Choice for Your Apiary

Choosing hive equipment means aligning your management style with the biological needs of your bees. An insulated hive is a powerful tool for achieving that alignment.

- If your primary focus is maximizing winter survival: Insulation is a decisive advantage, directly reducing the two biggest threats: cold stress and condensation.

- If your primary focus is colony health and buildup: By conserving energy, bees in insulated hives often build up brood populations faster in the spring, leading to more robust and resilient colonies.

- If your primary focus is reducing intervention: Insulated hives create a more self-sufficient environment that requires less emergency feeding and moisture management from the beekeeper.

Ultimately, choosing an insulated hive is a decision to work with the honey bee's natural biology, not against it.

Summary Table:

| Feature | Natural Hollow Tree | Insulated Beehive | Benefit to Bees |

|---|---|---|---|

| Thermal Stability | Thick wood walls (high thermal mass) | High R-value insulation (e.g., EPS) | Reduces energy spent on temperature control |

| Moisture Management | Porous wood absorbs vapor | Warmer inner walls prevent condensation | Prevents deadly moisture drip on winter cluster |

| Energy Conservation | Stable environment conserves bee energy | Passive thermoregulation | More energy for brood rearing, disease fighting, and honey storage |

| Seasonal Adaptation | Protects from summer heat and winter cold | Insulation buffers against external extremes | Less stress, faster spring buildup, higher survival rates |

Ready to work with your bees' natural biology?

Upgrade your apiary with HONESTBEE's premium insulated beehives and equipment. We supply commercial apiaries and beekeeping equipment distributors with wholesale-focused solutions designed to maximize colony health, winter survival, and honey production. By reducing energy expenditure on climate control, our insulated hives help your bees thrive, leading to stronger colonies and better yields.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can transform your beekeeping operation.

Visual Guide

Related Products

- Professional Insulated Winter Hive Wrap for Beekeeping

- Professional Insulated Plastic Bee Hives

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

People Also Ask

- How do insulation wraps and hive wraps protect bee colonies during winter? Maximize Survival & Honey Reserves

- What key factors should a beekeeper consider before wrapping a beehive? 3 Essentials for Winter Survival

- Is it always necessary to insulate beehives? A Guide to Winter Survival & Colony Health

- Why is it important to insulate beehives during winter? Boost Your Colony's Survival Rate

- How does insulation help bee hives in severely cold weather? Conserve Energy & Ensure Colony Survival