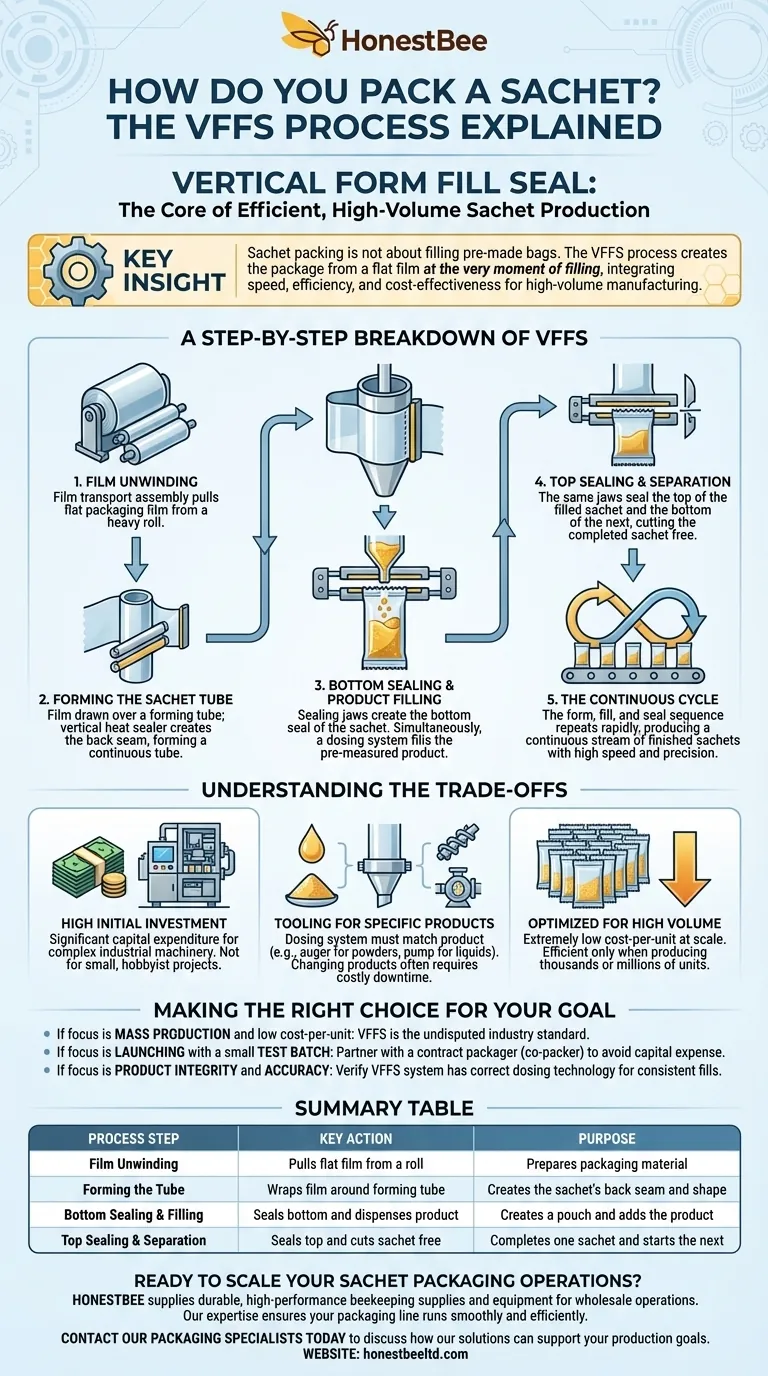

At the core of modern sachet production lies a highly efficient, automated method. Sachets are packed using a process called vertical form fill seal (VFFS), where a specialized machine transforms a flat roll of film into a finished, product-filled package in one continuous vertical motion.

The key insight is that sachet packing is not about filling pre-made bags. Instead, the VFFS process creates the package from a flat film at the very moment of filling, an integration that is fundamental to its speed, efficiency, and cost-effectiveness in high-volume manufacturing.

The VFFS Process: A Step-by-Step Breakdown

The vertical form fill seal machine appears complex, but it operates on a sequence of simple, linear steps. Understanding this flow demystifies how millions of sachets are produced with remarkable consistency.

Step 1: Film Unwinding

The process begins with a large, heavy roll of flat packaging film mounted at the back of the machine.

A system of rollers, known as the film transport assembly, carefully pulls the film off the roll and guides it toward the forming area.

Step 2: Forming the Sachet Tube

The flat film is drawn over a specially shaped funnel called a forming tube (or forming collar).

As the film wraps around this tube, it is converted from a flat sheet into a vertical tube of packaging. A vertical heat sealer then presses against the overlapping edges of the film, creating the back seam of the sachet.

Step 3: Bottom Sealing and Product Filling

A set of horizontal sealing jaws clamps shut below the forming tube. This action creates the bottom seal of the first sachet.

Simultaneously, a dosing system located above the forming tube dispenses a precise, pre-measured amount of product (be it a liquid, powder, or solid) down into the waiting, semi-formed sachet.

Step 4: Top Sealing and Separation

The film is then pulled downwards by a specific length—the height of one sachet.

The same horizontal sealing jaws clamp shut again. This single motion accomplishes two tasks at once: it seals the top of the just-filled sachet while also creating the bottom seal of the very next one. A blade inside the jaw assembly then cuts the completed sachet, which drops onto a conveyor or into a collection bin.

Step 5: The Continuous Cycle

This entire sequence—form, fill, and seal—repeats in a rapid, continuous cycle, producing a steady stream of finished sachets with high speed and precision.

Understanding the Trade-offs

While VFFS is the industry standard for sachets, it's essential to understand its operational context and limitations. It is a solution designed for a specific scale of production.

High Initial Investment

VFFS machines represent a significant capital expenditure. The machinery is complex and built for industrial use, making it unsuitable for small, hobbyist-level projects.

Tooling for Specific Products

The product dosing system (e.g., an auger filler for powders, a pump for liquids) must be matched to the product's characteristics. Switching between vastly different products, like from a liquid soap to a granular spice, often requires changing parts and recalibrating the machine, which involves cost and downtime.

Optimized for High Volume

The primary benefit of VFFS is its extremely low cost-per-unit at scale. The setup time and initial investment only become economical when producing thousands or millions of units. For very small batches, the process is inefficient.

Making the Right Choice for Your Goal

Understanding the VFFS process allows you to align your packaging strategy with your business objectives. Your decision should be based on your production volume, budget, and long-term goals.

- If your primary focus is mass production and low cost-per-unit: VFFS is the undisputed industry standard and the most efficient method for sachet packaging.

- If your primary focus is launching a product with a small test batch: Avoid the capital expense by partnering with a contract packager (co-packer) who already owns and operates VFFS equipment.

- If your primary focus is ensuring product integrity and accuracy: Verify that the VFFS system is equipped with the correct dosing technology for your specific product to guarantee consistent and accurate fills.

Ultimately, knowing how a sachet is made empowers you to make smarter decisions about manufacturing, partner selection, and capital investment.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| Film Unwinding | Pulls flat film from a roll | Prepares packaging material |

| Forming the Tube | Wraps film around a forming tube | Creates the sachet's back seam and shape |

| Bottom Sealing & Filling | Seals bottom and dispenses product | Creates a pouch and adds the product |

| Top Sealing & Separation | Seals top and cuts sachet free | Completes one sachet and starts the next |

Ready to scale your sachet packaging operations?

HONESTBEE supplies the durable, high-performance beekeeping supplies and equipment that commercial apiaries and distributors rely on for their wholesale-focused operations. Our expertise ensures your packaging line, much like a productive apiary, runs smoothly and efficiently.

Contact our packaging specialists today to discuss how our solutions can support your production goals.

Visual Guide

Related Products

- Professional Durable Customizable Blister Packing Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

People Also Ask

- What is the function of a sealing machine? Protect Product Integrity with Airtight Heat & Pressure Seals

- How do I choose a packing machine? A Guide to Strategic Investment and Seamless Integration

- What is the purpose of using modified sealing caps and industrial tape in bridging propagation? Boost Hive Acceptance

- What are the essential safety tips for operating a honey stick machine? Ensure Zero-Risk Production Efficiency

- What are the benefits of using packaging machines? Boost Efficiency, Cut Costs & Elevate Your Brand