At its core, a piston filling machine works for honey packaging by using a simple, highly precise mechanical action. A piston retracts within a cylinder to draw a specific volume of honey from a bulk container (hopper), and then extends to push that exact amount out through a nozzle and into your jar. This volumetric process is ideal for viscous liquids like honey, ensuring each container is filled accurately and consistently.

The real challenge in packaging honey isn't just filling a jar; it's controlling a thick, sticky, and temperature-sensitive product without waste or mess. A piston filler excels by providing mechanical precision that directly translates into consistent product volume, clean operation, and efficient production.

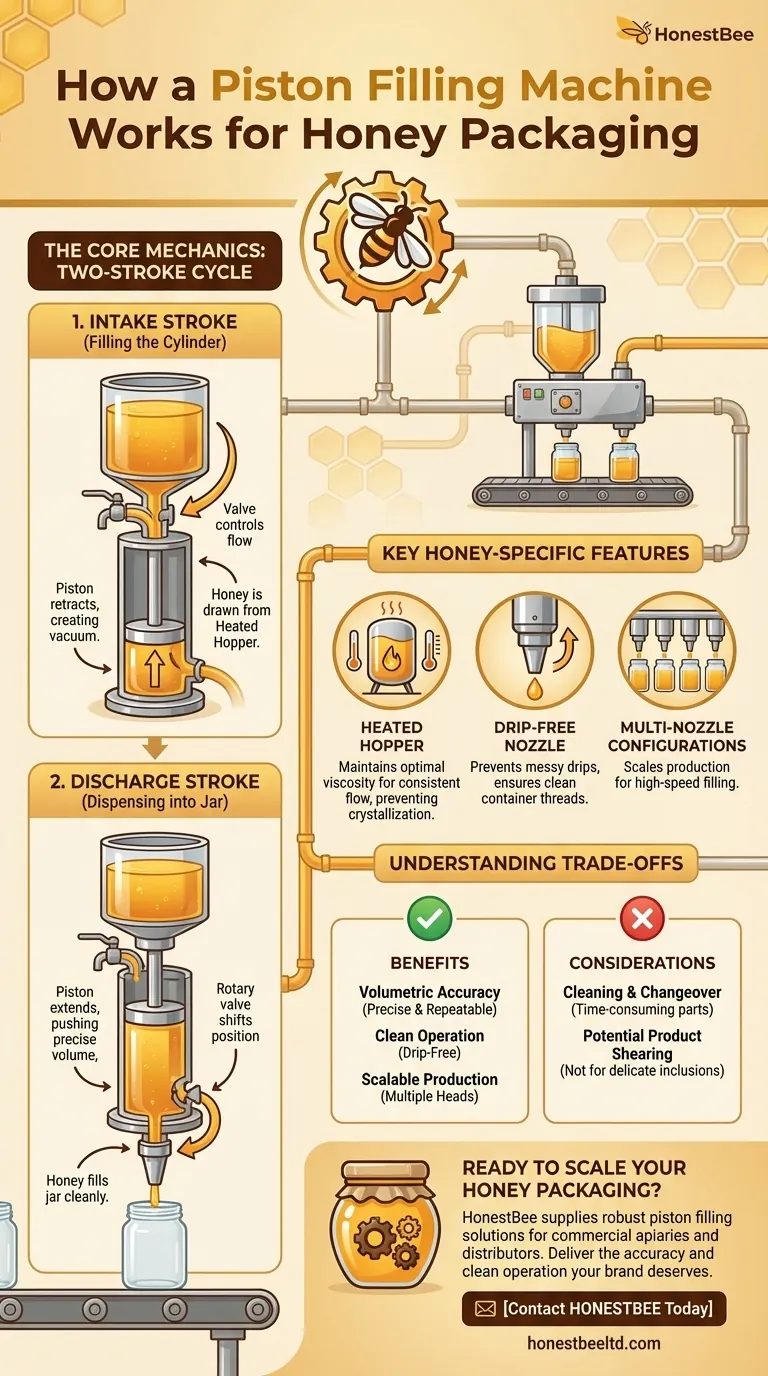

The Mechanics of a Piston Filler: A Step-by-Step Breakdown

To truly understand its value, we need to look at the two key phases of its operation: the intake and the discharge strokes. These are controlled by a valve that ensures honey only flows in the intended direction.

The Intake Stroke: Drawing Honey from the Hopper

The cycle begins when the piston pulls back within its cylinder. This retraction creates a vacuum, which siphons honey from the connected hopper into the cylinder. The volume of the cylinder, which can be adjusted, determines the exact amount of product that will be dispensed.

The Discharge Stroke: Dispensing into the Container

Once the cylinder is full, a rotary valve shifts position. The piston then moves forward, pushing the captured honey out of the cylinder and through a dispensing nozzle. Because the volume is pre-set, the fill level is extremely repeatable from one container to the next.

The Role of Valves and Nozzles

The entire process is governed by a valve system that directs the flow. During intake, it connects the hopper to the cylinder. During discharge, it connects the cylinder to the nozzle. This prevents any backflow and ensures a clean, one-way path for the honey.

Key Machine Features for Honey Packaging

Standard piston fillers are effective, but models designed specifically for honey incorporate features that address the unique challenges of the product.

Managing Viscosity with Heated Hoppers

Honey's thickness (viscosity) changes dramatically with temperature. The "double-layer insulated barrel" mentioned in high-quality machines is a heated or jacketed hopper. This feature keeps the honey at a consistent, optimal temperature, ensuring it flows smoothly and evenly throughout the packaging run.

Ensuring Accuracy and Preventing Drips

The primary benefit of a piston filler is its volumetric accuracy. However, dealing with a sticky product like honey requires another feature: a drip-free nozzle. Many machines include a "suck-back" function or a positive shut-off nozzle that pulls the last string of honey back after the fill, preventing messy drips on the container threads and conveyor.

Scaling Production with Multiple Nozzles

For growing operations, single-head fillers can become a bottleneck. Piston filling systems can be built with multiple pistons and nozzles that operate in parallel. This allows you to fill two, four, six, or more jars simultaneously, dramatically increasing your production speed.

Understanding the Trade-offs

While piston fillers are a powerful tool, they are not without operational considerations. Objectivity requires acknowledging their limitations.

Cleaning and Product Changeover

The precision of a piston filler comes from its components: the piston, cylinder, seals, and valves. These parts all come into direct contact with the honey. Cleaning them thoroughly can be more time-consuming than with simpler filling methods, which is a key factor if you frequently switch between different honey varietals.

Potential for Product Shearing

The tight tolerances and movement within the cylinder can "shear" the product. For pure, liquid honey, this is not an issue. However, if you are packaging honey with delicate inclusions like pieces of comb, the piston's action could potentially cause damage to those particulates.

Is a Piston Filler Right for Your Honey Operation?

Choosing the right equipment depends entirely on your production goals, product type, and operational scale.

- If your primary focus is consistency and a premium brand image: The high accuracy and clean, drip-free operation of a piston filler are essential for a professional-looking product.

- If your primary focus is scaling production from manual filling: A piston filler is the logical next step, offering a significant boost in speed and efficiency, especially with multi-nozzle configurations.

- If your primary focus is packaging many small, diverse batches: Carefully evaluate the cleaning and changeover time, as this downtime may impact the overall efficiency of your operation.

By understanding both the mechanics and the practical implications, you can make an informed decision that aligns with your specific business needs.

Summary Table:

| Feature | Benefit for Honey Packaging |

|---|---|

| Volumetric Piston Action | Ensures precise, repeatable fill levels for every jar. |

| Heated/Jacketed Hopper | Maintains optimal honey viscosity for smooth, consistent flow. |

| Drip-Free Nozzle | Prevents messy drips, ensuring clean container threads and packaging. |

| Multi-Nozzle Configurations | Scales production to fill multiple jars simultaneously. |

Ready to scale your honey packaging with precision and efficiency?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused piston filling solutions. Our machines are designed to handle the unique challenges of honey, delivering the accuracy and clean operation your brand deserves.

Contact HONESTBEE today to discuss the ideal piston filler for your operation and request a quote.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- How do automated honey-filling and labeling machines prevent honey laundering? Secure Your Global Supply Chain Integrity

- How does a weighing filling machine operate? Achieve Precise, Consistent Product Filling

- Why is a high-precision honey filling machine essential for rapidly crystallizing honey? Optimize Your Packaging Process

- Which type of honey is best suited for a gravity filling machine? Expert Guide to Low-Viscosity Filling

- How do industrial quantitative packaging machines contribute to the automated production of bee candy? Efficiency Guide

- How do honey filtration and automated filling equipment contribute to commercial value? Boost Your Brand & ROI

- What is a key feature of the new generation of the honey filling machine? The Advanced Electronic Control Unit

- What are the primary advantages of using automated honey-filling machines? Boost Efficiency and Product Quality